Call it a weakness, an obsession—whatever. But there’s something about the smell of assembly lube that makes us come a runnin’. For example, when our buddy Don Lower decided to build a 440 to swap into his old Barracuda project, he just couldn’t keep us (or our cameras) away.

The goal for the 440 was twofold: 1) Build an engine capable of taking Don into the 10.5-second quarter mile range at the track. 2) Use as many pieces from Mopar Performance as possible.

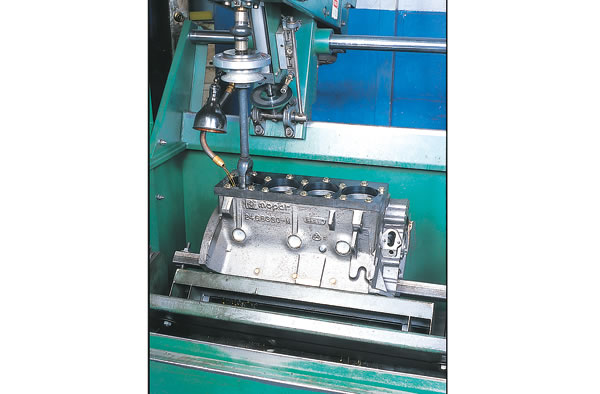

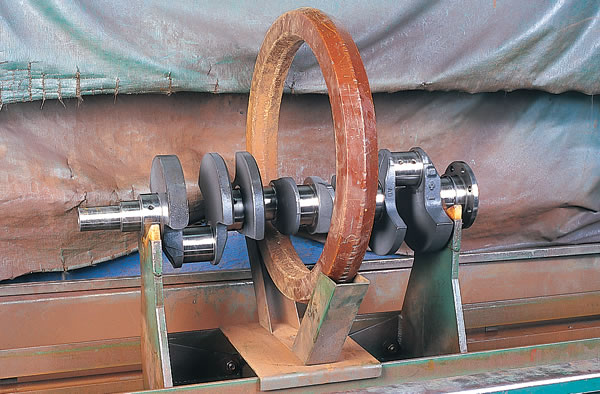

While browsing the Mopar Performance catalog, we found a cross-bolted, siamesed bore engine block, a 4.15-inch stroke race crankshaft, forged connecting rods, a .557-inch lift mechanical cam, and Stage VI cylinder heads. We followed the recommendations in the catalog’s High Performance Tips section and went with an M1 aluminum intake manifold and a 830 cfm Holley double pumper carburetor. Ignition is MP’s excellent electronic setup.

About the only things that weren’t acquired from Mopar Performance were the Crane roller rockers, ARP fasteners, Fluidampr harmonic damper, and the CSR electric water pump.The 440 will be backed by a 727 Torqueflite with an MP manual valve body and a Dana 60 rear axle with 4.56 gears.

We showed you how Trick Flow Specialties built a GM 440 LSX in an earlier post—now check out the slide show gallery to see how the Mopar guys assemble 440 cubic inches!

That camshaft is completely streetable! That is as long as your pistons aren’t to far down in the cyl’s giving you an actual low comp ratio “not 10.5:1”. I have the 590 version installed in mine, and also use 1.6:1 rockers. My heads flow a bit more and have a better shaped combustion chamber, but all things aside, if mine can be street driven yours will certainly handle the task!

440s have a 4.32 bore not a 4.25

Thank you, Mike. Correction made.

[…] had a much larger engine and greater horsepower. The Charger had a big-block 440 cu. in while the Mustang had a medium-block 390 cu. in. The Charger’s horsepower? 375 against the […]

What psi , gph electronic fuel pump do you use?

Hey i have a built 440 with 727 trans will trade or sell lots done to engine and trans will snap drive shaft in a heart beat under 200 miles on all power train have 15000. invested trade or Please call for more info and radiator too Thanks maybe you can use one there getting hard to find Robert call 661 300 1733 Hey and I am not a scammer all on the up and up Thanks Robert

U still have radiator for sell how much

I have a 440 40 over and notched pistons for the valves releaf I have 906 heads with 214 and 181 vavle

what kind of compression do I have

I think the block or the heads have been machined cuz the vavles are touching the heads