To build engines, you have to have tools.

To build an engine properly, you need the proper tools.

If you’re new to the high performance game and are building your first engine, we’ve compiled a list of twelve tools from our personal toolbox that ought to be in yours. None of these pieces are earth-shattering technology, but they do make engine building easier—with the final result being a powerful, reliable engine.

Tapered Ring Compressor:

A tapered ring compressor is the absolute best and easiest way to install piston and connecting rod assemblies. The tool gently squeezes the piston rings and actually funnels the piston/ring assembly directly into the cylinder bore without damaging or breaking the rings. This particular compressor body is milled for extra grip. These ring compressors are not universal—each is designed to fit a specific size cylinder bore. Summit Racing offers tapered ring compressors for just about every cylinder bore size.

Piston Ring Squaring Tool:

This tool is designed to square the piston ring in the cylinder bore so you can accurately measure ring end gap. In the old days, engine builders would use an inverted piston to set the rings in the bore, then measure down from the block deck to the ring to square the ring for measurement. The squaring tool pushes the ring 0.500 inch down evenly into the cylinder bore. The open configuration allows you reach through the tool and pull up on the ring to square it to the deck. That makes it much simpler to get an accurate end gap measurement. Piston ring squaring tools are available in various bore sizes.

Piston Ring Filer:

While many OE-replacement piston ring sets are available with pre-gapped top (compression) rings, most race-oriented ring sets have top rings designed to be hand-fit. That means ring end gap is measured and the ring is filed to fit its specific cylinder bore. A piston ring filing tool like this vintage Speed Pro tool makes the job much easier. The tool clamps or bolts to a workbench or in a vise and has a hand crank to turn the carbide filing wheel. You hold the ring against the stops and turn the crank to file one end of the ring. The carbide wheel makes quick work of piston rings, so be cautious when using it. Turn the crank slowly and use a “file, fit, file some more” procedure. You can find ring filing tools at Summit Racing, including fancy electric powered ones that are ideal if you do a lot of piston ring fitting.

Crank Socket:

Sooner or later, you’re going to be turning an engine over—when degreeing a camshaft, for example. One of the best ways to spin the crank is with this simple crank socket. It fits on the end of the crankshaft and accepts a half-inch drive ratchet or breaker bar so you can easily rotate the reciprocating assembly. There are crank sockets available for most common high performance engines.

Engine Brushes:

Remember what Mom said about cleanliness? It goes double when assembling an engine. Most professional engine builders clean an engine block multiple times, then wipe it clean with white towels to detect any traces of dirt and other residue. Engine brushes like the ones in this set from Summit Racing are a must-have to clean out engine oil galleries and other hard to reach spots. This set includes heavy-duty oil galley brushes, cam and lifter bore brushes, and a bolt-hole brush. If you build engines on a regular basis, be sure to replace your brushes periodically.

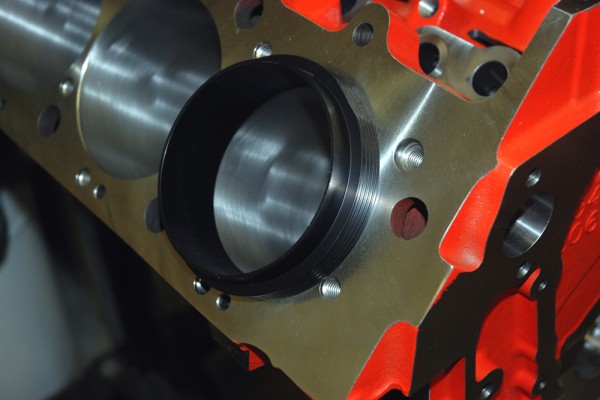

Harmonic Damper (Balancer) Installation Tool:

Installing a harmonic damper can be a pain in the you-know-where. You can’t hammer the thing into place—it has to be pressed on with an installation tool like one of these shown here. The tool screws into the threaded nose of the crank; it has a thrust bearing that gently squeezes the harmonic balancer onto the crank snout with no worries about damaging either the crank or the damper.

Degree Wheel:

Degreeing a camshaft and checking valvetrain clearances are critical procedures when building a performance engine. You’ll need a degree wheel to perform those tasks. When it comes to degree wheels, three things are important: size, visibility, and adjustability. This big 14 inch diameter wheel has easy to read silver graduations, plus a two-piece bushing arrangement that lets you adjust the wheel without removing it. Similar degree wheels are available at Summit Racing.

Dial Bore Gauge:

Every engine builder should own a dial bore gauge. It’s not as expensive as you think and is ideal for determining the size, straightness or taper of main bearings, rod bearings, and cylinder bores. This economy model is accurate to within 0.0005 inch. Once you’ve used a dial bore gauge, you’ll put away your snap gauges forever.

Pushrod Length Checker:

Pushrod length in an overhead valve engine is critical, particularly from a valvetrain geometry perspective. If you deck the block, mill the cylinder heads, or do something else to change the effective distance between the rocker arm cup and the lifter seat, you’ll need to measure pushrod length to keep valvetrain geometry correct. Adjustable pushrod length checkers like these from Crane for a big block Chevy (one tool is for the intake side, the other for the exhaust) are what you need. Simply insert the tool in place of a pushrod and adjust it until the correct length and geometry are found. Measure the length of the tool with a caliper and order the proper length pushrods for the application.

Oil Pump Primer:

You know how important it is to prime the oil pump before starting up a newly rebuilt engine, right? If you don’t prime the pump, you run the risk of firing up a fresh engine without having oil between the moving parts. The result could be scuffed parts from metal-to-metal contact—or worse. An oil pump primer prevents all that. It has a drive tip that fits a standard electric drill; the bottom end fits the oil pump’s drive tang. Simply spin the oil pump with the drill and watch the oil pressure gauge. When the engine has oil pressure, remove the tool and install the pump drive shaft and the distributor. The engine is now primed and ready to fire. This well-used pump primer is from Moroso.

Valve Spring Height Micrometer:

You need to determine the installed height of your valve springs so you can make sure they are properly matched to your camshaft and deliver maximum pressure without coil binding. A spring height micrometer is by far the quickest and most accurate way to measure valve spring installed height. You install the height micrometer just like you would a valve spring, then expand the tool until it has seated the valve, the valve locks, and the valve spring retainer. This simulated seat pressure allows ultra precise readings. This Crane tool is accurate to 0.001 inch.

Engine Storage Cradle:

Even a good quality engine stand can be a wee bit tipsy, particularly with a heavy, iron head big block bolted to it. Once your engine build is complete, it’s a good idea to install it in the car or put it on a dedicated storage cradle like this one. These cradles typically have easy-to-access mounting points—one end bolts to the bell housing flange while the other end has mounts that match the engine block’s side mounts. Summit Racing has engine cradles for virtually every popular V8 engine.

Shopping List

Harmonic Damper Installation Tool

Valve Spring Height Micrometer

Only things I dont have are a valve spring mic and a pushrod checker.

They are on the list. I just check everything when it comes back from the machine shop

Good list. Since you have a micrometer for valve spring installed height, I think I would add a valve spring pressure gauge to the list as well.

why does everyone think chevy, when high performance is talked about? they are historically the weakest car designer in America

If you really think that you have no idea how to build an engine!

Thank you I appreciate this post I would like to hear what your lists would for large diesel engines

Good engines, terrible cars

Torque wrench should be on that list. Number stamps, good straight edge. The list should be at least 30 toolsi would think.no valve springs would be installed without a valve spring compressor tool.

Seen a sbc take 600hp no problems. Try and put that through a windsor and you will have a pile of mashed potatoes and a short day at the track. Also cheaper to extract hp and torque out of a sbc than any other make. Period.

I have all of these except for the ring square. Which by the way can easily be accomplished by using one piston with a ring in the second groove. Install ring 1/4-inch in cylinder, insert the piston upside-down until the installed ring contacts the deck, remove piston, wha-la.

[…] Tool Guide: The 12 Tools Every Engine Builder Should Own … […]