Allow us to make a big giant generalization: building a dedicated drag race engine is pretty cut and dry. Since the aim is to cover a quarter-mile of straight asphalt in the quickest amount of time, you want an engine that makes its power at wide open throttle, all the time.

But build a multi-purpose engine using that formula and you’ll be building yourself a dog. When you build an engine that will see street or autocross duty as well as quarter-mile use, you want it to have a broad, flexible power curve, not one that comes alive only when the go pedal is on the floor.

That was the situation faced by Al Noe. Al’s 1967 Chevy Camaro is a fair-weather daily driver that also spends time on the autocross circuit and the drag strip. The F-body has a 388-cubic-inch stroker small block that specs out as follows:

- 350 four-bolt block bored .060 inches over

- 3.75-inch stroke Summit Racing forged crank, 5.7-inch Summit Racing H-beam rods

- 10.4:1 Wiseco flat top pistons

- COMP Cams Xtreme Energy hydraulic roller cam (230-degree/236-degree duration @ .050, .510/.520-inch lift)

- Trick Flow Super 23™ Street/Strip Aluminum Heads (72cc chambers milled to 70cc, 195cc intake/72cc exhaust runners, 1.460-inch dual valve springs)

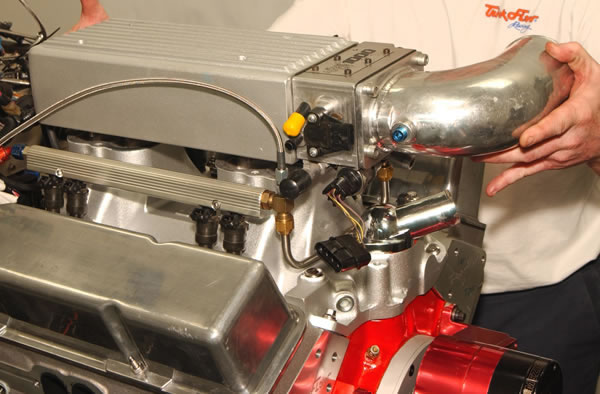

- Holley Stealth Ram Intake Manifold with 1,000 cfm ACCEL throttle body, DFI Gen7 controller, and owner-fabricated cold air intake

- Mallory 81 Series Dual-Magnetic Pickup Distributor, ACCEL 300 Digital Ignition Box

On Trick Flow’s Superflow dyno, the 388 made a respectable 484 horsepower at 6,000 rpm and 464 ft.-lbs. of torque at 4,800 rpm. Those are nice numbers for a dual-use small block—but not enough for Mr. Noe.

The Plan

Al wanted to update the 388 to be more competitive on the autocross circuit while staying as streetable as possible. He came up with three specific goals:

• Add approximately 50 to 60 peak horsepower

• Ability to rev up to 6,800-7000 rpm to allow autocrossing in second gear (few to

no upshifts to third gear)

• Reduce low end torque for better low-speed exits from the corners

The basic short block was updated with a Trick Flow Track Max™ Hydraulic Roller Cam (246-degree/254-degree duration @ .050, .588-inch lift). The idea of the bigger cam was to build more high-rpm power and bleed off some low-end torque. The Holley/ACCEL EFI system would remain as well (though its limitations would be revealed in testing, as you will soon see).

The big star in the makeover is Trick Flow’s Gen 1 small block Chevy cylinder head, the Super 23 Race CNC. Here are the specifications:

- CNC-ported 230cc intake/78cc exhaust runners

- CNC-profiled 70cc combustion chambers

- 2.080/1.600-inch stainless steel valves

- 1.530-inch dual valve springs rated to .680 inches of valve lift

- Assembled with 10 degree locks and titanium retainers, ARP 7/16-inch rocker arm studs, and guideplates

At first glance, the Super 23 Race CNCs look like overkill for the 388. In fact, Trick Flow recommends the heads for engines over 400 cubic inches and pushing 600 horsepower. But remember the plan—more power upstairs, less low-speed torque. The combination of fewer cubic inches, a big cam, and high-flow cylinder heads should meet the criteria quite well.

Test One: Holley Stealth Ram/ACCEL EFI

The 388 was assembled at Trick Flow world headquarters in Tallmadge, OH, then strapped to one of the company’s Superflow dynos for testing. The engine cranked out 533 horsepower at 6,500 rpm; torque was up by 12 to 476 ft.-lbs. at 5,200 rpm. Also, peak power levels shifted up about 500 rpm.

Even before the test, Trick Flow engineers knew they were leaving horsepower on the table. The Holley Stealth Ram was restricting airflow—its port openings are shorter than the ports on the Super 23 Race CNC heads.

“The height of the (Stealth Ram’s) port is limited because of how Holley cast the fuel injector bung into the port,” said Trick Flow’s Todd Hodges. “We attempted to port-match the intake manifold to the heads by making the intake’s ports as tall as possible, but they still hung down over the cylinder head ports by about 3/16 of an inch. That is not optimal for making maximum power.”

Test Two: Edelbrock Super Victor Intake/Holley HP 750 Carburetor

To help the 388 breathe better, Trick Flow replaced the fuel injection with an Edelbrock Super Victor Single Plane Intake Manifold and a Holley HP Series 750 cfm Carburetor. Designed to build power through 8,500 rpm, the Super Victor’s runners extend into the plenum area, increasing the manifold’s total volume. That means the Super Victor can handle lots of airflow. Trick Flow port-matched the manifold to the 2.110 x 1.25-inch intake openings on the Super 23 Race CNC Cylinder Heads.

After completing the intake swap, Trick Flow put the hammer down on the 388. The reward was even more power—565 horsepower at 6,800 rpm, a gain of over five percent with a simple induction change. Torque was up a tick to 485 ft.-lbs. at 5,200 rpm, with a flatter curve overall. Low rpm torque dropped as expected; it was down roughly 18 ft-lbs. from 3,500-4,000 rpm.

So the 388 works on the dyno—how does it perform in the car? Even with the Holley/ACCEL EFI reinstalled, Al says the engine “pulls like a freight train!” While he hasn’t taken the car to the track since the upgrade, Al expects the reborn stroker to shave ETs around 3/10s to a half-second and boost top speed by approximately four to five miles per hour. That extra top end power will come in handy in the twisty stuff as well.

Before you get all worked up about Al leaving horsepower on the table, be assured that he will be replacing the restrictive induction system with the Edelbrock Super Victor manifold and a four-barrel style throttle body EFI setup. Those 32 extra horsepower will sure help if someone ever gives Al a triple-dog dare.

Comments