Drag racers can be a discontented bunch. If a car is quick, it’s still not quick enough. Running five miles-per-hour faster is cool, but a couple more would be cooler yet. Cut a .010 reaction time? Gotta be a .005 next round.

That urge to do better naturally extends to horsepower. Things like reliability and cost are important factors, of course, but it’s horsepower and torque that get bracket heroes and Pro Stockers alike all jazzed up.

Summit Racing Equipment noticed there was a place for an engine package that would meet the power, durability, and affordability needs of bracket and sportsman-class racers. The company enlisted two-time IHRA Top Sportsman champion Marco Abruzzi to help spec out the combination.

Why 565?

Since the big block Chevy is used in more classes than any other (including its small block brother), engine choice was a no-brainer. Marco and Summit Racing’s Kirk Heinbuch, a longtime drag racer, settled on a 565-cubic-inch setup (4.600-inch bore, 4.250-inch stroke, 6.385-inch rod). They listed several good reasons for their choice:

• Familiar combination to racers

• Readily available components with minimal machine work required

• Large enough to make serious horsepower and torque

• Adaptable to many classes

Marco and Kirk focused attention on durability and ease of assembly.

“Horsepower is useless if the engine is always breaking parts,” Heinbuch said. “We built a lot of durability into our 565. For example, we used Crower stainless steel shaft rocker arms. They cost more than stud-mount rockers, but they provide rock-solid valve control and will probably outlast the rest of the engine.

“Another thing that we took into account is machine shop work. With our 565, the machining is already done—the block is final honed and decked, and the reciprocating assembly is avalable already balanced for the recommended JE pistons. Other than fitting pistons on the rods, file-fitting the piston rings, and normal prep, you can begin assembling our 565 the day you get the parts.”

Let’s take a look at the basic components in Summit Racing’s 565:

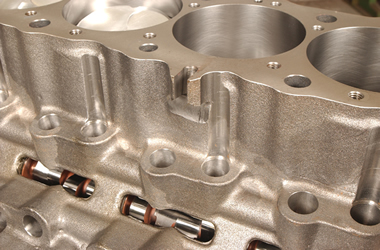

Block

• Dart Sportsman iron block, 9.800-inch deck height

• Fully machined and ready for assembly

• Cam bearings and freeze plugs installed

Reciprocating Assembly

• Eagle Specialties 4340 forged steel crankshaft, 4.250-inch stroke

• Eagle Specialties 4340 steel H-beam connecting rods with ARP 2000 bolts

• JE forged pistons, dome with two valve reliefs, gas-ported

Camshaft

• COMP Cams Drag Race series mechanical roller

• Duration: .277 degrees/.292 degress @ .050-inch

• Lift: .800 inch

• Cam ground for a 1-8-7-3-6-5-4-2 firing order (swaps cylinders four and seven) for extra high-rpm horsepower and reduced crankshaft harmonics

Cylinder Heads and Valvetrain

• Dart Pro 1 aluminum, rectangular port, fully assembled

• CNC-machined 119cc combustion chambers

• CNC-machined 355cc intake/138cc exhaust runners

• 2.300/1.880-inch valves, 1.625-inch dual valve springs

• Crower stainless steel shaft mount rocker arms, 1.7 ratio

• Crower Severe Duty .903-inch roller lifters, Trick Flow heavy-wall chromemoly pushrods

Oiling System

• Milodon Drag Race oil pan

• Moroso billet oil pump with pickup

• Moroso vacuum pump, ARP oil pump driveshaft

Air and Fuel

• Dart single-plane intake manifold, CNC port-matched to Pro 1 cylinder heads

• Quick Fuel QFX Series carburetor, 1,250 cfm, Dominator flange

• Aeromotive fuel pressure regulator

Ignition

• MSD Pro-Billet distributor

• MSD Flying Magnet crank trigger

• Moroso Ultra 40 Race ignition wires

• Autolite Racing spark plugs

Other Items

• TCI Rattler harmonic damper

• Cloyes Hex-A-Just timing set

• ARP fasteners, Fel-Pro and Cometic gaskets

• Clevite bearings

On the Dyno

Marco assembled the prototype 565 in his home shop; he added a CSR electric water pump, starter, and flexplate before hauling the engine to Ross Racing Engines in Niles, OH for dyno testing.

On the initial power pull, the 565 made 866 peak horsepower and 682 ft.-lbs. of peak torque. Ross Racing owners Ross and Tony Lombardi knew power was left on the table. They progressively richened the jetting on the Quick Fuel carburetor, eventually settling on #97 jets all around (equal jetting on primary and secondary sides). That did the trick—peak horsepower climbed to 920 at 7,500 rpm, with peak torque coming in at 726 ft.-lbs. at 6,300 rpm.

Kirk then added a new wrinkle—a 1,250 cfm Holley Dominator from Willy’s Carburetors. Well known for its circle track and NASCAR-spec carbs and fuel systems, Willy’s also does the Dominators for Summit Racing-sponsored Pro Stock drivers Greg Anderson and Jason Line. The company wanted to test a prototype of a new drag race carburetor it had developed, and Kirk volunteered the 565 as a guinea pig.

Swapping the Willy’s carb for the Quick Fuel air/fuel mixer produced results—942 horsepower at 7,200 rpm and 746 ft.-lbs. of torque at 6,200 rpm. The only tuning needed was setting the metering block valves two clicks richer.

At the Track

After the dyno sessions, the 565 (with the Willy’s carburetor) went into Marco’s Undercover Chassis Top Dragster for some real-world track testing. On his first outing, Marco won class in IHRA-sanctioned Quaker City Raceway’s Saturday night program. During a test and tune session at Summit Racing Equipment Motorsports Park in Norwalk, OH, the 565 rewarded Marco with a 7.48-second/176.60-mile per hour pass.

Summit Racing has all the parts you need to build this very engine on its shelves right now You buy the components separately, or in combos for the cylinder heads, valvetrain, and induction/ignition. That means you can build an engine just like this one, freshen an existing engine, or piece together a different combination. Considering the dyno and track results, though, it’ll be pretty tough to outdo Summit Racing’s 565 To Go.

Special Thanks To

• Ross Racing Engines, Niles, OH (216) 544-4466

• Abruzzi Racing Transmissions, Warren, OH (330) 369-1707

• Crower

• Dart

• Eagle Specialty Products

• JE Pistons

• Quick Fuel

• Willy’s Carburetors

Los motores Big Block son la mejor opciòn!

HOW MUCH DOES ONE OF THESE THINGS RUN FOR?

Hi Marc,

Summit Racing currently does not offer the engine as a complete package; however, they do offer parts combos based on this particular engine so you can build one in stages. Check out their website or give them a call for their current pricing. Thanks for reading!

ONALLCYLINDERS WEB PAGE OR SUMMITS WEB PAGE?

Marc Douglas Horak You’ll have a tough time finding any engine parts around here! Please visit http://www.summitracing.com, or call their fantastic customer service line at (330)-630-0230.

I Would Love to have This Engine in A Outlaw Nova Or Camaro.. :-)….

hell yes!

942 naturally aspirated horses. In love!

Nice build! Love the Willy’s carbs, very nice work.

[…] love engine builds—especially big cube engine builds. 565 to Go showed how to get 942 horsepower out of a 565 big block Chevy. Check out the step-by-step build for […]

How would someone order this engine? Is there a consolidated SKU for these components?

Save me a lot of clicks, what is the parts price total?

I’m building 565, 14.8.1, 357 afr, supper victor 2 ,cam 309/323. 377/291 .810/.810, 112 LC ,4600-7800 rpm up to 14.5.1 .what size carb and hp this eng should b making

need to know what size carb.need for this combo.

I now have this motor and it is now topped with a profiler sniper tunnel ram and an enderle injector. Upgraded from a timing chain to a baseline belt drive. Follow bam sports drag racing youtube for updates next racing season.