As is true with the selection of almost any automotive part, how you’re going to use the part you’re shopping for means everything.

Brake rotors are no different.

A good brake system is an important piece of the ultimate-stopping-power puzzle, but it’s not the most important part. Always remember that your brakes don’t stop your vehicle. Your tires do.

Ultimately, your brake system is only as good as your tires and suspension allow it to be. Upgrading your tires and shocks is an ideal first step to achieving the brake performance you seek.

As for brake rotors, you have a lot of options. We’ll cover many of them, highlighting the pros and cons of each. There are many types, most of which are differentiated by the type of cuts on the rotor surface—slots, dimples, holes, etc. The surface cuts allow more air to reach the rotor surface, more effectively dissipating heat which allows your brakes to run cooler.

The downside to the cuts is that by reducing the rotor’s surface area, you’re also eliminating some braking force. Which is why when selecting brake rotors, application is everything.

Solid surface rotors

Solid surface rotors

Solid, or smooth-surface, brake rotors are typically made of solid cast iron, and are most often found in standard OE applications on non-performance vehicles. The upside of solid surface brake rotors is that they typically have a longer life than brake rotors with cut surfaces. They are relatively quiet and don’t produce much dust compared to other rotor types.

Choose a solid surface rotor if you’re simply looking for an OE replacement option for your daily driver.

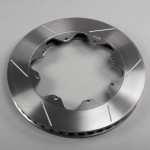

Slotted surface rotors

Slotted surface rotors

Slotted rotors provide higher friction levels than solid surface or smooth brake rotors, making them a popular choice among competition drivers and heavy truck operators. The extra bite provides enhanced stopping power for trucks towing heavy loads. On the downside, brake pad life will be slightly less and hard braking at higher speeds will emit some pedal flutter.

Choose a slotted surface rotor if you drive a truck or SUV, do a lot of towing, or are a performance race car driver who prefers the durability of slotted rotors to drilled rotors.

Cross-drilled surface rotors

Cross-drilled surface rotors

Cross-drilled brake rotors offer even more friction and stopping power than slotted rotors. Uneven rotor wear is one of the primary concerns. More serious is the risk of stress cracks forming from rigorous racing conditions. Racers should consider other options unless drilled rotors are required as part of the rules of a particular racing league.

Choose drilled brake rotors if you drive in lots of rainy conditions. Drilled rotors provide the best bite in wet conditions. Also, if you’re looking for lightweight rotors, drilled rotors typically weigh about 20 percent less than their non-drilled counterparts.

Cross-drilled and slotted surface rotors

Cross-drilled and slotted surface rotors

And somewhere in the middle lie these rotors, featuring both types of surface cuts. They offer something of a performance compromise between drilled and slotted rotors. Rotors that are both drilled and slotted are best for street applications.

Choose cross-drilled and slotted rotors if you’re looking for long brake life and good stopping performance in street driving. These rotors do a great job dissipating heat. However, heavily drilled rotors will overheat and experience premature fade under repeatedly aggressive racing conditions.

Slotted and dimpled surface rotors

The addition of dimples offers a popular alternative to those looking for the aesthetics of drilled rotors with the stress-crack resistance of non-drilled rotors.

Choose slotted and dimpled rotors if you love the drilled look but need the toughness of a non-drilled rotor for vigorous braking in high performance racing applications.

By following these basic guidelines, combined with the right set of tires and well-tuned suspension, you’ll be obliterating the competition in no time.

[…] pad material and helps guide you in your brake pad shopping. Also, be sure to check out our post How to Choose Aftermarket Brake Rotors after watching this […]

[…] According to Baer, “This condition is the reason for reverse slotting or cross drilling rotors, as it allows a pathway for the gasses to escape.” Read about how to choose aftermarket brake rotors here. […]

[…] Where bedding your brake pads is about properly transferring pad material to your rotors and cooking out resins used in the brake pad manufacturing process, seasoning your brake rotors is about burning machine oils from the rotor surface and establishing a wear pattern between the pad and rotor. Most importantly, seasoning your rotors is about relieving internal stresses within the metal that makes up your rotor. (Read How to Choose Aftermarket Brake Rotors here.) […]

[…] with Drilled rotors. to support my opinion: slotted vs. cross drilled rotors? – AnandTech Forums How to choose the correct brake rotors __________________ "First they ignore you, then they laugh at you, then they fight you, […]

There’s likely a good reason behind why OEMs use solid rotors.

[…] How to Choose Brake Rotors […]