Anyone who has ever spun a 9/16-inch wrench on a hot rod knows the engine block is where it all begins. There are lots of options available—new and used, iron and aluminum, OEM and aftermarket.

We’re going to examine a typical V8 engine block—in this case a Chevrolet Performance Bowtie iron block for big Chevy engines (part number NAL-19212195 from Summit Racing) to show you what goes into a modern engine block, and what to look for when buying a used block or getting a block prepped at the local machine shop. The information presented applies to other OE and aftermarket blocks as well.

This Chevrolet Performance Bowtie big block Chevy iron block is a fine example of a modern performance block. It is a tall deck style (10.200-inch), four-bolt main block that features 8620 steel main caps, blind head and accessory mounting bolt holes, and a deck configuration that accepts any big block Chevy cylinder head. You can safely bore the cylinders out to 4.600 inches in diameter while maintaining a .250-inch minimum cylinder wall thickness. It’s one stout block.

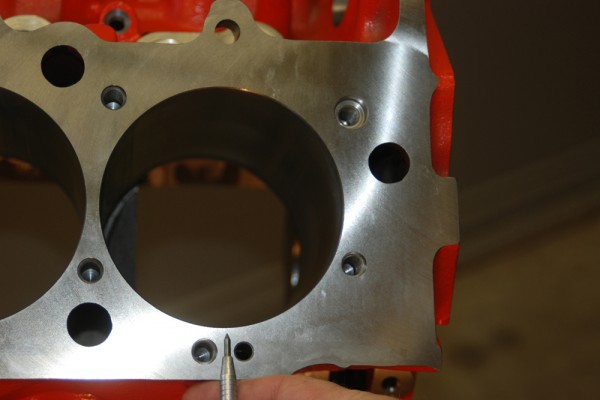

During the power stroke, the pistons exert considerable force on the major thrust surfaces of the block as they push down on the connecting rods. Pistons on the driver’s side of the engine wear against the inside (lifter valley side) bore surface, while pistons on the passenger’s side of the engine wear against the outside (exhaust manifold side) bore surface as shown in the photo. This force can create egg-shaped cylinders in used blocks.

Some cylinder bores end up thinner in critical locations due to core shift during the casting process. This is particularly important to know when overboring a block. Chevrolet Performance uses an ultrasonic testing device to measure cylinder wall thickness, and includes a sonic test check sheet with many of its high performance blocks. It tests the blocks at two points: 1.75 inches down the bore and 3 inches down the bore. The corner cylinders like the one shown are also tested along the outboard edges. For a naturally aspirated engine, a wall thickness of 0.250-inch on the major thrust side and 0.200-inch on the opposite side is desirable. This Bowtie block sonic-checks out at 0.302-inch minimum and 0.395-inch maximum thickness on the major thrust surface—and that’s with a big 4.560-inch cylinder bore.

Camshaft bores can be misaligned or the wrong size from the factory. For our Bowtie block, Chevrolet Performance has a tolerance dimension between 2.1209 and 2.1198 inches (a range of 0.0011-inch). If the bore dimension tolerances vary by 0.0005 inch either way, camshaft problems can develop. Cam bores are usually measured at four points—12:00, 3:00, 6:00, and 9:00 o’clock. Measuring in more than one position determines how out-of-round a bore is. Since a cam bore doesn’t have caps, the only way to correct cam bore alignment is to overbore the holes and install oversize camshaft bearings.

Diameter and alignment influence the shape of the main bearing bores. Both must be close to ideal in order to avoid bearing failures. The tolerance dimension for our Bowtie block is between 2.9378 and 2.9373 inches (with caps in place and torqued to spec). The bores are measured at 12:00 and 6:00 o’clock, 10:00 and 4:00 o’clock, and 2:00 and 8:00 o’clock. If any bore is out of alignment by 0.003-inch or more, the block should be align honed.

Lifter bores are important too—you want smooth bores that allow the lifters to move easily without binding. In a Chevy, the size of the bore is very important because oil pressure is provided to the lifter by way of holes that connect to the lifter oil galleries. If the lifter-to-bore clearance is too tight, there’s a chance the lifters will bind. If they’re too loose, excess oil will bleed around the lifters and reduce engine oil pressure. Chevrolet Performance specifies a lifter bore diameter of between 0.8442- and 0.8432-inch. On our Bowtie block, each bore measured 0.8439-inch, well inside the tolerance range.

Obviously, cylinder bores should be round. To achieve that, all race blocks and many high performance street blocks are bored and then honed with torque plates installed. These plates simulate the stresses the cylinder heads place on the block—they actually distort the block when bolted down. Chevrolet Performance CNC-machines the bores of its Bowtie blocks, then hones them with torque plates installed. After machining, each bore is measured parallel with the block, 90 degrees to parallel, at the top of the bore, in the middle of the bore, and at the bottom of the bore. The entire process is repeated twice—once with torque plates and once without. With the torque plates installed, our bores measured from 4.5603 to 4.5606 inches in diameter—almost perfectly round with no taper.

Since the main bearing bores are machined with the caps in place, the caps are numbered to insure the right cap goes with the right main bore saddle. Mixing up the caps can lead to out-of-round bores and possible crank damage due to binding or bearing failure. The arrows on the caps should all point forward.

One thing you should check on any block, new or used, is the oil galleries. We’ve seen some blocks where the galleries weren’t finished and one block with a piece of drill tooling broken off in it. Chevrolet Performance does inspect all Bowtie blocks to ensure all oil holes are properly drilled. Our block has all oil holes drilled and accounted for.

Another consideration is block deck height. This is the distance between the main bearing bore (crankshaft) centerline and the top of the block. Standard small block Chevy deck height is 9.025 inches. Passenger car big block deck height is 9.800 inches, and “tall deck” truck big blocks measure 10.200 inches. To accommodate large cubic inch displacements, many aftermarket racing and performance big Chevy blocks like our Bowtie are tall deck.

Late model Mark V and most Mark VI production-based Chevy big blocks do not have provisions for a mechanical fuel pump. Mark IV production blocks and Chevrolet Performance Bowtie blocks do have a fuel pump boss. When inspecting blocks with pumps bosses, make sure the pushrod hole is actually drilled. We’ve seen some blocks where the hole is either missing or not completely bored.

All three center main caps have outer bolts that are splayed (angled) 16 degrees. Splayed caps provide more clamping power, so they are stronger than conventional straight bolt caps. Our Bowtie block is equipped with nodular iron caps that can handle up to 800 horsepower. Past that point, you should consider a block with billet steel caps. Chevrolet Performance installs 8620 steel caps on its Bowtie race blocks and 4140 steel caps on DRCE drag race blocks.

[…] the first installment of Block Talk, we told you why a modern CNC-machined block is a great foundation for a high performance engine. […]

[…] of course, but you may only find out if/when you try to increase the bore (See photo 3 of 12):- https://www.onallcylinders.com/2013/0…-engine-block/ Reply Reply With […]

I’m confused. The BBC bore spacing is 4.84″. If you bore the cylinders out to 4.60″, the thickest the walls can be is the centerpoint of the 2 cylinders, which is 4.72″, which would make the cylinder wall thickness 0.12″, not 0.25″. Where am I going wrong?

Jon K Do your math again.One half of 4.6 is 2.3 same for the next cylinder 2.3 + 2.3 = 4.60 4.84-4.60 = .24 wall thickness between the two cylinders

Didn’t know the ,the numbers thanks a lot will try to remember thanks a lot

how much u want for that block i have a bowtie motor break a rod mess the block up need a goog use tall deck had 598 cubic in motor want to build it back please give me a call 803 565 1997 clarence mitchell or 803 774 4900 work

What to look for when buying a block v8 for my Holden ute 2007 mod start from scratch is my guess it’s my dream

[…] Download Image More @ http://www.onallcylinders.com […]

Great information but can we have more info on ‘what to look for when buying a used engine’. Also, love to read more about a long block and a short block engine. Thank You!