Carburetor spacers have two main tasks: insulate the carburetor from engine heat to keep the incoming air and fuel cooler, and act as a tuning aid to produce more power. There are many carb spacer options to accomplish those goals–wood, aluminum, and more–so the the question becomes:

Which carb spacer is best for your application and its intended use?

Spacer Materials

Let’s start with a spacer’s insulation properties. These are largely determined by the material a spacer is made from. There are four typical types of spacer material: wood, phenolic resin, polymer (plastic), and aluminum. Each has a different thermal conductivity (heat transfer) rating that tells you how well the material insulates against heat. The lower the rating number, the better the material insulates. Let’s look at each type:

Aluminum is the worst insulating material of the bunch, with a thermal conductivity rating of 1,665.1. An aluminum spacer does offer three advantages—it’s very durable, is easily altered to help tune the intake charge, and is the only spacer material allowed by many racing sanctioning bodies.

Wood is the best insulating material, with a thermal conductivity rating of 1.02. It’s also cheap and easy to shape. However, a wood carburetor spacer is the least resistant to gasoline and chemicals. It soaks up liquid easily, causing the spacer to warp, become porous (causing vacuum leaks), and break down faster. If you use wood spacers, inspect them regularly and replace if necessary.

Phenolic Resin has a thermal conductivity rating of 2.01. While not as good an insulator as wood, it is far more resistant to fuel and chemicals, making a resin spacer more durable.

Polymer is less expensive than phenolic resin. But with a thermal conductivity rating of 3.90, it does not insulate as well. Some polymers have been developed that insulate nearly as well as phenolic resin, so it pays to do your homework before you buy.

Spacers as Tuning Devices

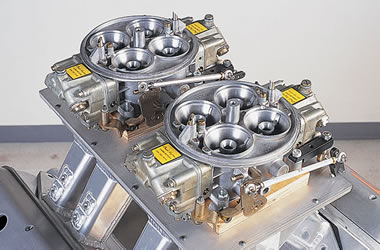

Spacers often fall into one of two categories. Open plenum spacers increase the total area of the intake manifold, which helps build mid-range and high-rpm horsepower. That makes them ideal for racing. Wood and aluminum are the better material choices for racers who reshape or stack spacers. Phenolic resin and polymer are good choices for spacers that won’t be altered. Sanctioning body rules often dictate the type of spacer material you can use.

Four-hole plenum spacers are designed to increase the velocity of the air/fuel charge, which helps build low and mid-range torque. Spacers made from phenolic or polymer are ideal for street cars and trucks, providing the best balance of insulation and durability.

Spacer designers and racers often play with spacer configuration to get specific tuning effects at certain points in the engine’s rpm range. Aluminum and wood spacers are ideal for this as their openings are easy to reshape with a die grinder.

Another tuning trick is to stack open plenum spacers. This increases the spacers’ insulation factor and creates a mini-tunnel ram effect by giving the incoming air and fuel a taller, straighter shot into the manifold. Aluminum, wood, and phenolic resin spacers can be stacked.

Now that you know some of the basics concerning carburetor spacers, you should have a better idea of which type fits your needs.

I bet you can coat the wood in fiberglass resin so it won’t soak up the fuel

What about runners on EFI cars such as Ford? You know, between upper and lower intake.

Machine an aluminum insert to line inner oak spacer.

lol, 100$ of work on a 50 cent spacer

with a highrise manifold on a big block ford, do I need a spacer ? thanks for more info

How about HVH spacer ?