Marc Sorger is a diehard racer. At age 13, he and his dad built a 1957 Chevy with a tunnel-rammed 301 small block and 5.13 gears (“I won a bunch of races and money with that car,” Marc recalled). He is licensed in NHRA’s Motorcycle, Super Street, Super Gas, Super Comp, Top Dragster, Advanced ET, Comp, and Funny Car classes; his quickest and fastest quarter-mile pass is 5.04 seconds at 304 miles-per-hour in CLASS.

Then there’s Marc’s road racing gig.

He has a National Auto Sport Association (NASA) competition license that also allows him to compete at Sport Car Club of America (SCCA) and International Race Drivers Club (IRDC) events. His playground of choice is NASA’s American Iron Series, where he runs a 2008 Mustang with support from The Mustang Shop of Kent, WA.

Designed to be an affordable way for amateur road racers to compete and have a genuine shot at winning races and national championships, the American Iron Racing Series may be the ultimate Ford Mustang vs. Chevy Camaro battleground.

The Series consists of three classes:

• American Iron (AI) is limited by a power-to-weight ratio and other factors to keep the cars on an even playing field. The class is open to any American pony car made since 1960 running four, six, and V8 engines.

• American Iron Extreme (AIX) has more liberal build rules than AI. It’s pretty much an unrestricted class with no power-to-weight ratios or spec tires.

• American Iron Spec Iron (SI) is a spec class for 2005-2010 Mustang GTs. Cars can be modified with Ford Racing parts and performance packages and must use a spec Toyo tire.

Marc competed in the AIX class. He upgraded the Mustang’s 4.6L with all-forged internals and a centrifugal supercharger cranking out 20 psi of boost. That engine made 743 horsepower at the rear wheels, but had cooling issues that led Marc to search for another engine.

“The supercharged engine proved reliable, but I had issues keeping the coolant temperatures under control during long stretches at wide open throttle,” Marc said. “After fighting that problem for a year, I sold the engine and got a 358-cubic-nch engine and transmission that was raced in Mark Martin’s Roush/Yates Ford in 2003. We swapped the flat tappet cam for a custom Crane Cams mechanical roller cam with the same specs. We also installed a 950 cfm Quick Fuel carburetor, and I made a set of equal length stepped headers for it. That engine made 680 horsepower at the wheels, which is roughly 840 at the flywheel.”

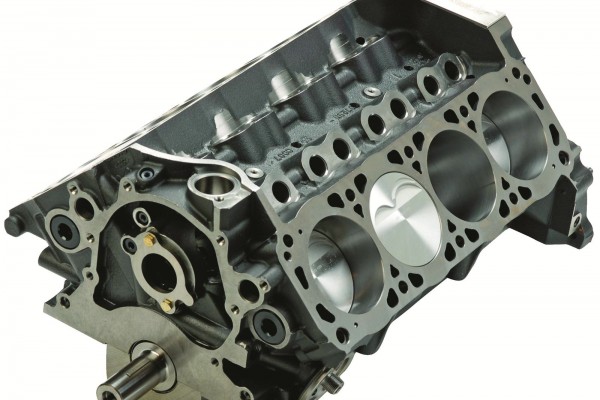

While Marc did well in American Iron Extreme, he also wanted to be able to run in the American Iron class as well to improve his chances of winning a championship in 2014. Since American Iron is governed by power-to-weight ratio rules, he had to build yet another engine to meet the criteria. He went with a Ford Racing 363 Boss short block assembly with a COMP Cams Xtreme Energy solid roller cam and a pair of Edelbrock Victor Jr. aluminum heads. Topping the long block is an Edelbrock Victor Jr. intake with a 750 Holley double pumper.

The 363 made 482 rear wheel horsepower on the dyno and will make even more once the carburetor jetting is sorted (it was very lean during testing).

“It’s making more horsepower than I thought it would, and way more than American Iron power-to-weight ratio rules allow,” Marc said. “I will have to put a restrictor plate on the engine to make the car legal for competition.”

Marc recently sold his Mustang to a fellow American Iron competitor who will campaign the car in 2015. Marc will be handling the crew chief duties.

“The person that bought the car is a long time customer of mine and The Mustang Shop,” Marc said. “He has been road racing a stock Mustang Cobra and drives both a new supercharged Ford Raptor and a GT500, so he knows his way around horsepower. I will be crew chief on the car and setting up the chassis to suit his driving style. He will do well in American Iron.”

But that doesn’t mean Marc will be without a fun ride of his own. He loves the Mustang’s 363 power and manners so much, he’s building another one for a 1984 Bronco pre-runner truck that he will take off-road racing. It’s hard to keep a good racer out of the driver’s seat.

Check out the slideshow above as we show you the highlights from the Iron Man 363 build. Then, watch the video below to hear what all those cubic inches sound like. You too can build a rip-snorting, overpowered 363 just like Marc’s. He sourced all of the parts from Summit Racing, and the company has put together American Iron Mustang Combos so you can duplicate the build.

[…] Download Image More @ http://www.onallcylinders.com […]