As the powerplant of choice for the 2006-2013 Corvette Z06 and 2014-2015 Camaro Z/28, GM’s LS7 is a 427-cubic-inch, 500-plus horsepower monster. It was the first production engine to use forged titanium connecting rods and titanium intake valves, and the only production V8 built by GM with fully CNC’d heads and a 7,100 rpm rev limit. The LS7 officially made 505 horsepower, but output was closer to 512 in 2011, the first year for the X-pipe exhaust and the last year for dual cats.

All is not sunshine and rainbows with the LS7, though. One big issue is prematurely worn valve guides. The problem is caused by non-concentric valve guide and valve seat centerlines, thought to be a result of machining errors made by the supplier which manufactured LS7 cylinder heads for GM’s Powertrain Division. The non-concentricity causes excessive side loading of the valve stems, which in turn wears out the valve guides.

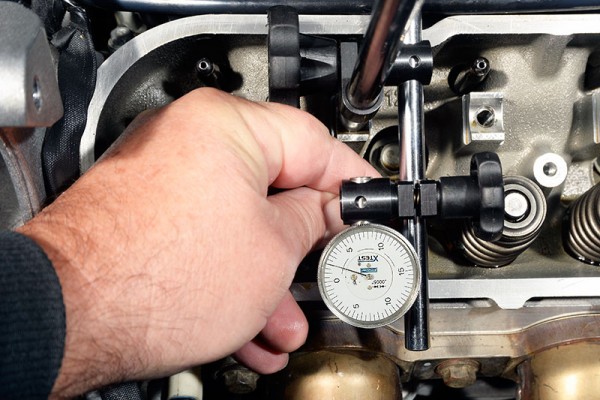

The valve guide problem does not affect all LS7 cylinder heads. The Corvette Action Center web site has a good article by Hib Halverson on how to properly perform the GM-specified field test for valve guide wear. Dubbed the “wiggle test” by the DIY Corvette community, the procedure measures the valve-stem-to-guide clearance.

The test can be done with the engine installed in the car if you use a valve spring compressor that can remove the springs without removing the heads. Fortunately, Summit Racing offers that exact style of valve spring compressor. Made by valvetrain tool specialist LSM Racing Products, this compressor is designed specifically for use on the LS7 and its offset intake rocker arms. The tool can also be used on other Gen 3 and Gen 4 LS engines. You can learn more about it in this in-depth product review of the LSM Racing valve spring compressor.

The Corvette Action Center also has a very in-depth article on the LS7 and its valve guide wear issues. Once you read it, you’ll be the All-Knowing LS7 Guru of your neighborhood!

What is the fix for the LS7 vale problem?