Welcome to Part Six of Project Thunderbolt, our LS Miata swapfest.

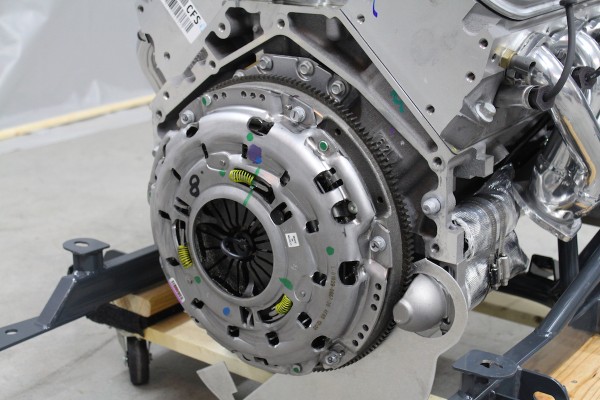

In this update, we’re ready to mate the Chevrolet Performance LS376/525 engine with the Tremec T56 Magnum six-speed for good. But before we could join them in mechanical matrimony, we needed a clutch that combines excellent holding power with great drivability. Summit Racing came to the rescue (again!) with a Chevrolet Performance T56 Magnum Transmission Installation Kit. From the bellhousing to the dust covers, this OEM quality kit includes everything needed to get this important job done right.

Once the engine and transmission were bolted together, we lowered the whole assembly into our Miata for the final test fit. This step was necessary to locate our transmission crossmember and frame rails, and to make sure all of our chassis modifications have been done properly. All of that checked out, so we removed the engine assembly and welded together the modified firewall area, transmission tunnel, and interior.

Now we’re getting somewhere!

ENGINEER, you should visit with Chip Foose!!! This is quite the hot rod project you or whoever has chosen, but you are definitely up to the chore. You are young and have great skills. I am impressed!!! Keep up the great work. Larry

WOW! That’s one awesome engine swap for such a small car. I know it will be one wild and exciting ride on a short wheel based Mazda Miata.