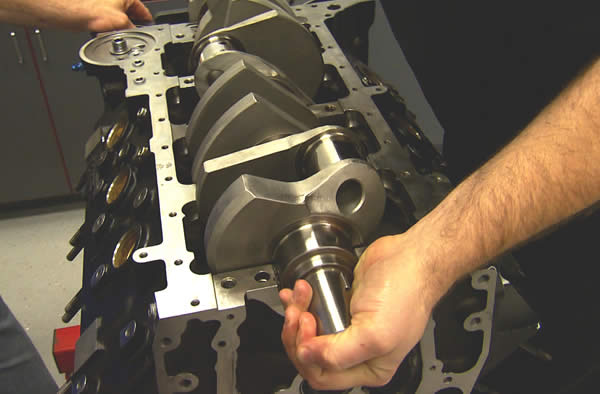

The crankshaft is the backbone of any Mouse or Rat.

Without a good, strong crankshaft, your high performance Chevy engine (or any engine, for that matter) risks catastrophic injury. Whether you’re building a small or big block from the ground up, or adding serious modifications to your existing mill, it’s important that you match your crankshaft to your application and performance expectations. That’s why we turned to the experts in the Summit Racing technical department for the lowdown on how to choose the right Chevy crankshaft.

Matching Crankshaft to Engine

We’re focusing on Chevrolet engines here, so let’s start with some basic specifications you should know when choosing a crankshaft for your engine:

Bore and Stroke for Common Chevy Engine Displacements

| Cubic Inches | Stroke (inches) | Bore (inches) |

|---|---|---|

| 302 | 3.000 | 4.000 |

| 327 | 3.250 | 4.000 |

| 346 | 3.620 | 3.900 |

| 350 | 3.480 | 4.000 |

| 364 | 3.620 | 4.000 |

| 377 | 3.480 | 4.155 |

| 383 | 3.800 | 4.000 |

| 383 | 3.750 | 4.030 |

| 396 | 3.760 | 4.096 |

| 402 | 3.760 | 4.125 |

| 427 | 3.760 | 4.250 |

| 454 | 4.000 | 4.250 |

| 502 | 4.000 | 4.466 |

| 540 | 4.250 | 4.500 |

| 632 | 4.750 | 4.600 |

Whereas stock engine configurations bolt together with factory specs, stroker combinations often require special measures to ensure that the crankshaft and connecting rod combo fit within the given space. This could mean custom rod lengths, crankshaft strokes, and additional engine clearancing.

That’s a topic for a whole ‘nother post.

For now, let’s focus on finding the right crankshaft for your stock-configuration Chevrolet engine.

Crankshaft Materials

This first thing to consider is crankshaft material and how it relates to your specific application. There are four main types for material used for crankshaft construction: cast or nodular iron, cast steel, forged steel, and billet.

Cast and nodular iron crankshafts are what typically come from the OE manufacturer. Most cast iron crankshafts have a tensile strength in the 65,000-80,000 psi range. Some companies, including Scat, will mix in graphite with its cast iron cranks to improved fatigue resistance. Nodular iron crankshafts raise the bar slightly, offering a tensile strength closer to the 100,000 psi range.

If you’ve got a stock or mildly modified street application, cast or nodular iron cranks are an affordable way to go. According to Carl Pritts, an adviser in Summit Racing’s technical department, these crankshafts are usually good for 300 to 400 horsepower reliably and can withstand some occasional weekend track usage.

Cast steel crankshafts are the next step up from iron. Cast steel begins life as a liquid and is then poured into a mold before cooling. This is a relatively inexpensive manufacturing process, but the steel construction makes these crankshafts much stronger than OE designs. According to Pritts, cast steel crankshafts are ideal for applications up to 500 horsepower reliably.

“Cast crankshafts are ideal for street applications running pump gas with good driving manners,” Pritts said.

Pritts says these cranks are best used with 327 to 383 cubic-inch engines with 8.5:1 to 10:1 compression ratio, mild cam, and possibly a mild power adder like low-horsepower nitrous kit. For larger cube engines with 11:1 to 14:1 compression and major upgrades—large-port aluminum heads, big camshaft, large headers, and even a power adder—he recommends going with a forged crankshaft.

Forged steel crankshafts are ideal for highly modified engines and most race applications. During the forging process, a singular chunk of molten steel is compressed and essentially squeezed into its final state using heavy-duty presses and dies. This manufacturing process, along with the type of steel used, makes forged crankshafts very sturdy when installed properly.

Crankshafts are typically made from one of these high-strength steels:

- 1053: carbon steel with tensile strength around the 110,000 psi range

- 5140: chromium steel with tensile strength around the 115,000 psi range

- 4130/4140: chromoly steel with tensile strength at about 120,000-125,000 psi

- 4340: nickel chromoly with about 140,000 psi tensile strength

There are also two types of forging processes: twist and non-twist. In the simpler twist method, the dies are arranged in a single plane, but the raw forging must be twisted to create the offset journals in the crankshaft. The non-twist forging process, which is now used by most aftermarket crankshaft manufacturers, uses more complex dies to simultaneously forge all four crank throws. In theory, this causes less internal stresses in the forging than the twist method.

Depending on the type of steel and manufacturing process, Pritts says forged crankshafts can handle between 600 and 1,000 horsepower reliably.

At the very top of the food chain are billet steel crankshafts. These cranks start as a solid bar of high-grade steel and are then carved and machined into the final crankshaft shape. Because of the machining process, these are considered by many as the strongest crankshafts and are often not given rated power limits. However, that same machining process also makes billet crankshafts the most expensive. They are typically used in higher-end, ultra high-horsepower race vehicles.

Internal vs. External Balance

According to Pritts, one of the most common mistakes is not having the crankshaft properly balanced. All crankshafts must be balanced to your piston and connecting rod combination, and usually the crankshaft manufacturer will list how its product is intended to be balanced.

Internally balanced crankshafts can use the counterweights alone to balance the crankshaft. Externally balanced cranks often require external items to be properly balanced. This can be added at the harmonic damper and/or flywheel. According to Eagle Specialties, Chevy 305 and 350 engines are typically internally balanced applications. Chevy 400 and 454 are often externally balanced.

Regardless, you should always send your rotating assembly out to a properly equipped machine shop to have the final balance done.

Other Considerations

Crankshafts may be manufactured with a variety of additional process to improve fatigue resistance or lighten the overall mass. For example, many steel crankshafts can be induction hardened, shot peened, or cryogenically treated for added strength. You can learn more about those processes here. Crankshafts may also have radiused journal fillets, which place added material where the journals meet the crank cheeks—a typical weak point. To lighten the overall weight, crankshafts may also be gun-drilled or come with slotted counterweights.

5 Common Pitfalls

Pritts says there are five common mistakes people make when choosing a crankshaft:

- Shopping at swap meet: “Parts here are generally worn out or broke,” Pritts said.

- Budget building and expecting the crankshaft to last.

- Not having the assembly properly balanced.

- Not properly considering clearances on strokers.

- Using incorrect bearings on a forged crank.

By doing your homework and avoiding the common pitfalls, you’ll find the right Chevy crankshaft for your engine.

Great article presented in layman terms that us non professionals can comprehend.

How is “Cast Steel” allowed to be marketed, since it’s nothing but a fancy name for cast iron.

Steel has less than about 2% of carbon. Cast iron has considerably more. Eagle is on record as saying their “cast steel” has even more carbon than “nodular iron”, which is a high grade of cast iron.

Therefore, “cast steel” is a lie, it’s deceptive advertising, and the only purpose is to mislead the customer into paying more money.

What is the size of st crank shaft I have bought one and I need to if it is actually st or something else

Arma-steel vs cast steel might be a good topic for explanation as they possibly have a little deception in common. There are a good quantity of old iron cranks around from GM sporting the Arma steel logo. They were superceded by cranks marked with an N I believe for “Nodular” possibly another name for “pearlitic malleable iron” also a GM possibly other makes crank material. Would be nice to have the 4 compared by elasticity hardness and tensile strength as the various grades of steel all are in Machinery’s Handbook.