Whether it’s in your bathroom or on your race machine, car plumbing can be an exercise in frustration—especially when you finish the job, turn on the faucet or switch on the pump, and discover you have more leaks than flow.

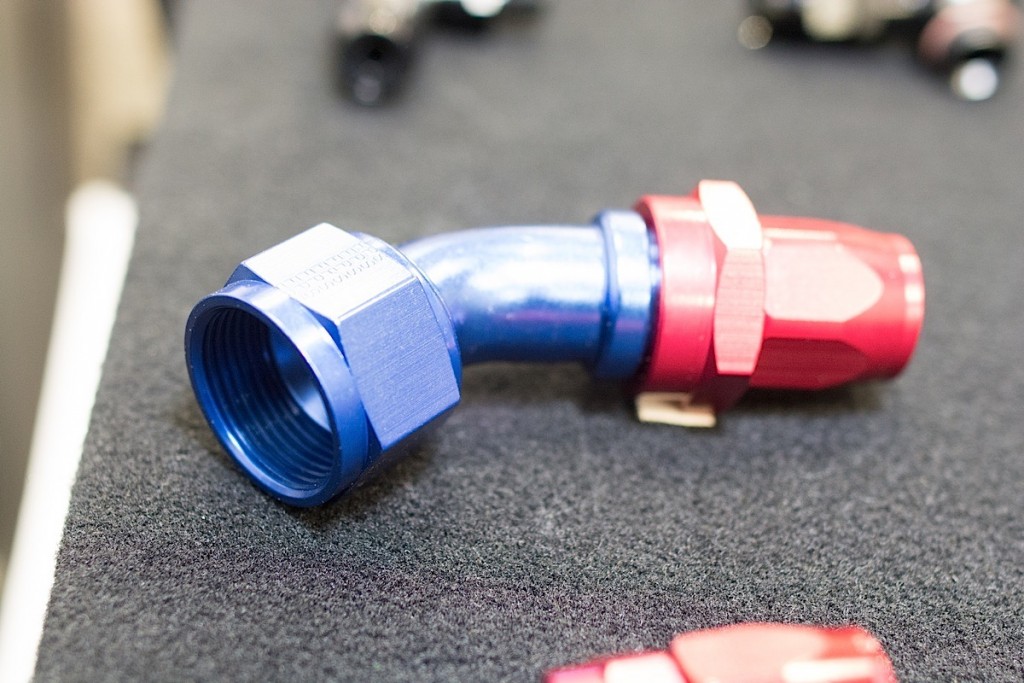

While we can’t really help you with your bathroom, we can show you how to assemble leak-free hose and fittings for your car, with a little help from the plumbing guys at Earl’s. We’ll be plumbing a Holley “blue” electric fuel pump using Earl’s Swivel-Seal AN fittings, Perform-O-Flex braided hose, and Summit Racing 3/8-inch steel hard line.

The basic assembly procedures we’ll use in our example apply to most automotive plumbing. We also have a list of tools that will help you do a first-class plumbing job, plus some general tricks and tips to make you the AN Plumbing Master of the Universe. Well, at least of your neighborhood.

Hose and Fitting Tips

1. You’ve probably heard this one before, but AN stands for Army-Navy. Established many years ago by the U.S. military as a common measurement for hose and fittings, it designates the outside diameter (o.d.) of the rigid metal tube that is compatible with each size fitting. These dash sizes are expressed as the numerator of the fraction, with the denominator always being 16. For example, a –04 port is 4/16, or 1/4 inch.

Here’s a list of common AN to fractional equivalents:

-02 AN = 1/8 inch

-03 AN = 3/16 inch

-04 AN = 1/4 inch

-05 AN = 5/16 inch

-06 AN = 3/8 inch

-08 AN = 1/2 inch

-10 AN = 5/8 inch

-12 AN = 3/4 inch

-14 AN = 7/8 inch

-16 AN = 1 inch

-20 AN = 1 1/4 inches

-24 AN = 1 1/2 inches

-32 AN = 2 inches

2. Over-tightening is one of the most common ways to destroy an aluminum fitting. It can distort a fitting’s seat or cone, making it prone to leaks. Dirt and debris on the sealing surface can also cause a fitting to leak. Make sure to clean out a hose/fitting assembly with solvent after putting it together to remove shavings or other debris.

3. Believe it or not, vacuum hoses take more abuse than any other type. It is important to match the hose to the vacuum rating of your application. If a hose is installed beyond the minimum bend radius, or has been kinked or damaged, its vacuum rating will be reduced. For severe vacuum applications, such as dry sump oiling systems, an internal support coil may be needed. Earl’s has these coils in various inside diameters.

4. Abrasion is one of the leading causes of hose failure, hence the popularity of hose like Earl’s Perform-O-Flex hose with tough stainless steel braided covers. For racers looking for less weight, Earl’s Pro-Lite 350 hose has a braided nylon cover and weighs far less than steel braid-covered hose. No matter which type of hose you use, make sure to route it to avoid sources of heat and contact with other components. Use support clamps to keep the hose from flopping around and rubbing against frame rails, headers, and other stuff.

5. When cutting braided hose, clean up any burrs and ragged edges on the end of the hose. This helps to ensure a secure, leak-free seal between the hose and the fitting. Wrap the end with electrical tape before cutting to help minimize burrs and ragged edges.

Parts List

Earl’s Five-Inch Vise Jaw Liners (EAR-005ERL)

Earl’s Hose Assembly Lube, Eight-ounce bottle (EAR-184004ERL)

Summit Double-End AN Wrench Set (-3 to -20 AN) (SUM-900125)

Summit 37 Degree Flaring Tool Kit (SUM-900311)

Summit Tubing Cutter (SUM-900500)

Summit AN Hose Cutter (SUM-900040)

I ordered Earl’s braided stainless brake hoses for my 98′ GMC Sonoma pick up. When they arrived the fitting looked ok (I ordered -3AN with banjo ends and after some measuring it looks like the right size. But, I measures the hose end outlet size and it came out to 3/32”. Is this the proper size for my application or did I make a mistake somewhere? I don’t want to restrict the flow of fluid to the calipers as it looks smaller that the hard lines inside diameter.

Mark, that particular truck is plumbed with ¼” hard line throughout, which is equivalent to -4AN braided line.

Do I have to run .020 orifice on return line for nos