I just bought a new, digital timing light to replace my old original light. When I push the button, the timing moves but I’m not sure I know exactly what’s really going on here. There’s probably an easy answer but it escapes me! Thanks

D.L.

Jeff Smith: What you are using is what is commonly referred to as a dial-back timing light. A normal timing light flashes the instant the Number One spark plug fires. This works great as long as you are only setting initial timing and only if you can line up the marks from the timing tab on the engine to the TDC mark on the balancer. A typical timing tab offers numbers up to 14 to 16 degrees Before Top Dead Center (BTDC). But if you need to set your initial timing at a figure greater than what is offered on the timing tab, you have to guess, which is never good. The simplest way to compensate is to use an MSD timing tape. These are adhesive tapes that adhere to the balancer and offer accurate timing numbers so that you can use a standard timing light to check maximum advance. There are several tapes on one sheet based on the diameter of the balancer.

But if you work on multiple cars/engines, it is time-consuming and cumbersome to attach a timing tape to each engine. A dial-back light is far more useful. The original dial-back lights employed a simple dial on the back of the light. In this case, you rev the engine to maximum advance and use the dial to line up the TDC mark with 0 (zero) timing on the tab. The dial on the light then indicated the total amount of advance.

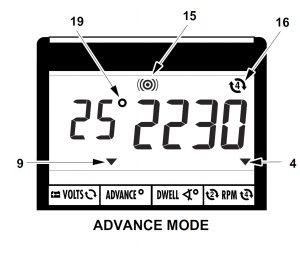

The modern version is a digital dial-back light. Instead of a dial, these lights generally use a digital display screen with not just the amount of timing dialed back but also all kinds of other information. Instead of a traditional knob, these digital lights generally use up or down arrows to adjust the timing mark. You use these lights exactly the same way as the traditional dial-back lights, but the display and the options can be somewhat confusing. With the engine revved to full advance, the technique is the same — adjust the crank TDC mark until it lines up with the zero (TDC) mark on the indicator tab and the number on the back of the light will indicate the amount of total timing.

For example, the Innova digital timing lights that Summit Racing sells offer a display that will show system voltage (it uses power from the battery to run the light, so volts is accessed), dwell (if your engine is equipped with points), rpm, and the amount of timing the light has been delayed. The light that we referenced (PN INO-5568) is pretty sophisticated, but Innova does offer others that are less expensive.

For example, the Innova digital timing lights that Summit Racing sells offer a display that will show system voltage (it uses power from the battery to run the light, so volts is accessed), dwell (if your engine is equipped with points), rpm, and the amount of timing the light has been delayed. The light that we referenced (PN INO-5568) is pretty sophisticated, but Innova does offer others that are less expensive.

What’s interesting is that the modern distributorless ignition systems (DIS) employed on all late model engines don’t require a timing light and don’t even offer a TDC mark on the balancer. It’s a new digital world out there.

What’s modern distributors less ignition don’t require? It is help diagnose accurately some one fault found.I’m fallow use diagnose scanner and timing light.

So does it allow you to set the timing at engine speeds greater than idle?

I use a timing light on a number one spark plug in my 1984 Ford F-150 truck V6 5.8 and are you just like Amy on the number one spark plug and all the sudden I forgot to Market and I did not see the city Mark so I put the light down into the mark on the number one spark plug and now they’re not have any power what did I need to do

I understand how to use dial back timing lights. But I don’t understand how they work. How does it advance the flash exactly the number you want without knowing rpm (in some cases)? I’ve searched the interwebs and found nothing but how to use one.

Dial-back lights actually work by delaying the signal. Let’s say that with the dial-back at zero, the timing is actually 10 degrees Before Top Dead Center (BTDC). Some lights use a dial while digital units use a button with a digital display screen. Now if you move the dial or hit the button until the light reads zero on the harmonic balancer, the display will read 10 degrees. It has nothing to do with rpm. When the engine advance triggers the light, it flashes. All the dial does is delay it so you can “zero” the mark and then read the timing on the display. Does that make sense?

Makes perfect sense. In my mind the light was having to advance the flash. Thanks

So if I set the dial on 10 degrees, then turn the distributor so the pulley TDC Mark aligns with the TDC on the crankcase it is then set to 10 degrees yes?

The timing should be 10 degrees on my car, so I tried this theory Jeff.

I set the dial on zero just to test and it read correctly on the crank marks.

When I set the dial to 10 degrees, the mark on the pulley moved away from original setting..

Is the idea to then adjust the distributor to realign that ‘zero’ mark and then timing will be 10 degrees ?

Thank you

Ian

When you dialed the timing light to 10 degrees, the mark on the balancer moves to 0 (zero) on the timing tab on your engine. The point of this exercise is to rev the engine up to where maximum timing occurs and use the dial back feature to check because all factory tags stop well shy of total advance timing. This way you can check your mechanical advance to check the total timing. Always check total advance with vacuum advance unhooked. So if your total timing is 34 degrees (24 dgrees + 10 degrees initial) then set your light at 34 and rev the engine to just above maximum advance and see if the mark lines up with 0. If it does not, then depending upon which side of 0 the mark lies, you will know what the total timing is. If it reads 4 degrees advanced then the actual timing is really 32 degrees total timing. If it reads 2 degrees retarded – then the timing is really 36 degrees – re-adjust the light until the timing reads zero to verify.

I guess the real question is “How does the timing light know how much delay 10 degrees should be?” Does it calculate differently for a 4, 6, or 8 cylinder engine, or just estimate by RPM??

Cn I use an old dwell meter to check RPM on my solids state Harley?