Mike Petralia, owner and chief bottle washer at Hardcore Horsepower & Dyno in Franklin, TN, is no stranger to hot small block Ford builds. So when it came time to do another one, he wanted to zig where everyone else had zagged. The goal was big power and big cubic inches from a high compression, naturally aspirated combination.

Short Block

The foundation was a 4.125-inch bore Dart SHP iron block and a 4.100-inch stroke Scat forged steel crankshaft. The longer stroke also required long rods, so Mike went with 6.200-inch Scat H-beam rods designed for small block Chevy rods. The reason for the mouse rods is due to the Scat crank’s 2.100-inch diameter rod journals, which are the correct size for small block Chevy rods. That allowed Mike to choose from a much larger pool of connecting rods. The block/crank/rod combination yields 438 cubic inches—a bunch for a small block Ford.

Mike dove into the JE Racing catalog and found a set of forged pistons for the build. They had an advertised +6.5cc dome, 1/16-1/16-3/16-inch ring lands, and a .927-inch pin bore that matches the small Chevy rods. The other important factor was the 1.230-inch compression height. If the Dart block was milled down to a 9.480-inch deck height, the pistons would be very close to a true “zero” deck (piston top even with the cylinder bore opening), which is great for making naturally aspirated horsepower. Total Seal Maxseal piston rings sealed the deal. The file-fit rings feature a ductile-iron gapless top ring, 1-piece Napier-style second ring, and reduced-tension oil scrapers that would work well with the vacuum pump Mike planned to run.

Cylinder Heads and Valvetrain

Mike wanted the 438 to be a true “Windsor.” That meant no cheating by using a set of Ford Cleveland-style heads. Trick Flow had exactly what was needed with its CNC-ported High Port® 240 aluminum heads. The High Ports are designed for large cubic inch engines or smaller engines running lots of nitrous or boost. The heads have 240cc intake and 95cc exhaust runners finished off with Trick Flow’s high resolution CNC Competition Port work for maximum flow and velocity. Mike had the heads flat-milled to reduce the 67cc combustion chambers down to 62cc. With the JE pistons, compression came out to 13.90:1.

Mike found a nice solid roller cam with specs that looked really good on paper. But when he test-fitted the cam in the 438, there was literally zero piston-to-valve clearance. He turned to Comp Cams for a custom grind. Hardcore Horsepower has worked closely with Comp engineers many times trying new ideas and making big power, but this one turned out to be a tough challenge. Comp had to build a cam with lobes that would meet the power and rpm goals, and it had to fit in the engine as-built.

The result was a solid roller with over .740 inches of valve lift. The cam had .017-inch less intake and .020-inch less exhaust lift at Top Dead Center overlap—the critical point for piston-to-valve clearance—but had the same .050-inch duration and more total exhaust valve lift on the exhaust side than that first “paper” grind! You can read more about the importance of lobe lift at TDC overlap at the end of the story.

The 460 lbs./in. valve springs installed on the Trick Flow High Port heads were rated to .680-inch max valve lift, but Mike wanted something a bit stiffer to control the gnarlier Comp Cams bumpstick. He swapped the spring for a set of stiffer 640 lbs./in. Crower springs. Considering the heads’ large 2.10-inch intake valves and the faster acting 1.7:1 Jesel shaft rockers used, the Crower springs provide better valvetrain stability at higher rpms.

Mike also got a set of Comp Cams Hi Tech pushrods. The 3/8-inch diameter, .135-inch wall pushrods offer a lot more stiffness to complement the Crower springs, but also needed a lot more clearance to run. The pushrod holes in the Trick Flow were milled to get the proper clearance.

Oiling System

The Milodon Racing oil pan is designed to fit the common Fox-body chassis. Mike found some spots that needed extra clearance, like around the Dart block’s large billet steel main caps. The oil pan’s extra-wide passenger side kickout limited starter clearance, even when using a Powermaster high torque mini starter that can be clocked to clear most headers and oil pans. The pan was massaged to fit.

Induction

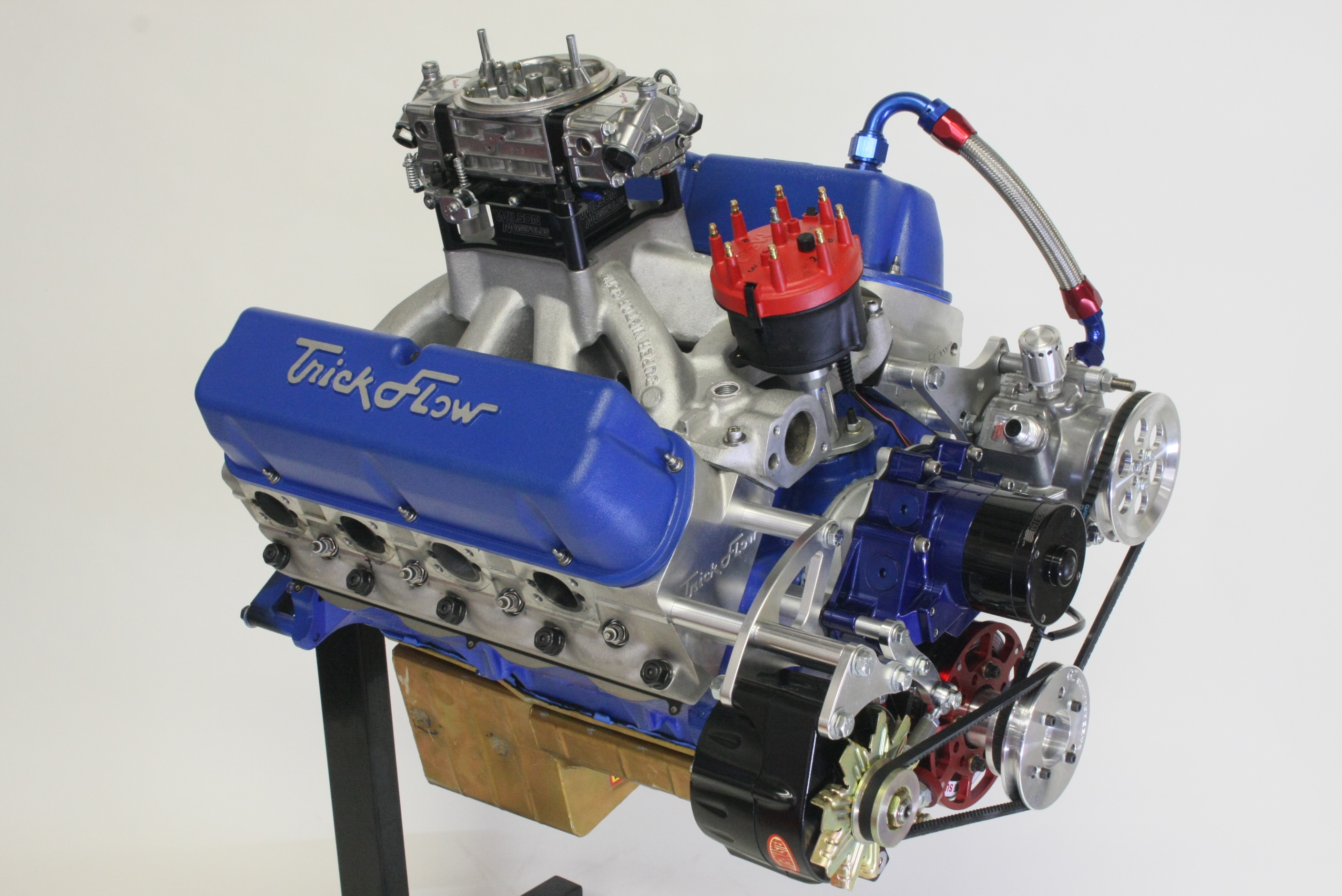

Mike used a Trick Flow R-Series intake manifold and a 950 cfm Trick Flow by Quick Fuel double-pumper carburetor. The manifold was port-matched to the High Port heads; the carburetor was run right out of the box.

Other Items

Mike had to machine custom spacers to properly mate the front engine accessories—a Powermaster alternator, MSD crank trigger, GZ Motorsports vacuum pump, and a Meziere Enterprises billet electric water pump. Luckily, the water pump had dual-side inlets allowing the lower radiator hose to mount on the driver’s side of the engine. Otherwise, you’d never be able to see the timing pointer.

To really set this build apart, the Trick Flow cast valve covers were painted to match the engine block’s classic VHT Ford Light Blue color.

Dyno Results

During the dyno session, Mike found some power with carburetor jetting and air-bleed modifications and some timing adjustments. Best peak power (735 horsepower) was found using a two-inch tall HVH Super Sucker carb spacer. Mike also tried a 1 7/8-inch tall Wilson Manifolds open spacer that sacrificed about four horsepower at the top end, but added 12 ft.-lbs. more peak torque (621 total). Either spacer combined with the already-tall Trick Flow intake put the carburetor pretty high above the engine. If you run this engine in a car, a giant hood scoop is definitely in order!

Summit Racing put together special engine combos to help you duplicate the build.

Piston-to-Valve Clearance: It’s Not About Maximum Lift

When inexperienced engine builders talk about piston-to-valve clearance (PTVC), they always think it’s about maximum valve lift. That’s not the case at all as the pistons are never anywhere near the valves at maximum lift. The clearance issue happens when the piston is at or near Top-Dead-Center, with both valves still open during the overlap cycle of the cam. The amount of valve opening at this point is critical, and can be affected greatly by the cam’s Lobe Separation Angle (LSA). A wider LSA (114°-118°+) will keep the valves a bit further away from the pistons at TDC-overlap. A tight LSA (110°-104° or less) will put the valves closer to the pistons at TDC-overlap. Advancing or retarding the cam can change piston to valve clearance as well.

How much would this build cost?

Using a aluminium Dart block, 4 bolt main caps and the same components what would the cost run out at

might this engine produce same hp and torgue with Borla 351 cross ram induction

I got the same block/bore, but I’m using a much milder, solid lifter cam, Cleveland heads and Comp cams valve train. I haven’t finished it yet but it’s specd for 2500-6500 rpm. Comp cams software predicted out put is 630 HP at 6450RPM. Max torque is at 498 at 4000 RPM.

I’m putting it in a 4 speed, daily driver ’65 Mustang Shelby Clone

How would valve to valve clearance be an issue on a wedge head?

There is none…

This my engine built by Mike. The first 1/4 mile pass in my 88 GT Fox yielded a 9.62 @ 140 mph with a 3800 rpm footbrake launch on Hoosier 30 x 9″ radial slicks. It is a beast. Nice job, Mike…Thanks, Rod in TX

Could you post the Cam info? Like a part number? I am building the same short block and i’m having p-v clearance issues with the cam I am using too. Thanks!

Rod how much does your 88 GT weigh? Good runs!

You know I really don’t get the mention of Chevy so often. Those parts aren’t Chevy at all. Not even in a basic forge. The Center to center dimensions and even forging dimensions are all not GM. 1 Hole is related and could be anyone Else’s. Its like giving them credit where its not due!!!!

Just the connection rod was used with a chevy crank pin. He had ordered so he could regrind the (Ford Scat stroker crank rod journal) or just order It with the Chevy size. (Very common to make special one off builds easier and less $.) ( much cheaper than . . . Too special order a one off custom built set of ford rods at a special length) This way its possible to choose from the millions of Chevrolet connecting rods available off the shelf . So now it was posible to set his own piston to deck hight. This was done because of the dome top pistons he used to arrive at a specific hight he needed. That is the only thing Chevrolet related to the build. And it’s just a journal dimension. Purley just a Part No. That’s all.

It’s listed as a Chevrolet part number. Why buy a set of custom one off set of rods for a Ford when there are readily available rods for a small block Chevrolet that are the correct dimensions? I’ve got 6.5″ billet steel rods in my 434 and guess what? Howards lists them from 5.7″ to 6.5″ in .100″ increments for a Small Block Chevrolet.

What’s the total cost of build ?

Do u build engines for other people if so how much for same exact building I just read about

This build needs a bigger intake , a ported 2828 or a chi forsure , would like to see some custom headers on this build as well , i made 714 hp with a smaller cam 672 solid and less compression 12.1 with my 434 and 240s , i like that camshaft alot , nice build man , highport 240s love big racing intakes ,

[…] Download Image More @ http://www.onallcylinders.com […]

Do you sell the same motor to the public turn key crate engine if so how much would it be ?

if you gota ask how much it costs then you cant afford it … believe me i know … stupid poor guy that wants big power !

That’s not very nice calling someone stupid. Very bad form. Wanting to get the best bang for your buck is not stupid, it’s smart.

I could easily afford just about any engine in the world and I would ask the same question…

A real good read, I built a 438 and just ran it on a chassie dyno 1990 mustang c4 it made 579.64 hp at the wheels at 6900 and 475 # torque. On the track 1/8 mile it went 5.80 at 119 on E85 on motor. I did build it for spray..

Are these motors available for purchase in a crate motor package

I’ll build u it 25k

I have a 1966 cobra with a 351:427 stroker motor. I want more horse power. I like what I see in your engine and the power is what I’m looking for. What is the price for a long block minus valve covers, oil pan ?

Don’t waste your money, just build a 454 or 460 Windsor, 4.125 or 4.155 bore, 4.25″ stroke. You’ll spend the same, make more power everywhere and be faster.

How much for this exact motor delivered to Sydney Australia

Hi Team

What is the price for this engine landed in nz

What about using a stock block stroked to 427 12:1,comp a 980 carb 680 lift cam.Can it be built.