Chevy fan or not, you can’t deny the performance potential of GM’s LS series engines. They share most internal and external components with each other and fit in nearly any place a Gen I Chevy small block can fit. When you see Mustang folks run LS engines, you know GM hit a home run.

We set out to assemble a 500-ish horsepower, high-torque LS engine for one of our projects, a 1971 Buick GS. We wanted a minimum 6.0 liters (366 CID) of displacement and an iron block for strength. There are several iron-block 6.0 liter LS engines from the factory. Most notable are the LQ4 and LQ9 Vortec, used in the GM’s 1500 and 2500HD series trucks (Gen III/IV LS truck engines are all Vortec).

The LQ4 has 9.4:1 compression and the LQ9 clocks in at 10.0:1 compression. We might use a power adder down the road, so we went looking for an LQ4. It’s a regular inhabitant of most salvage yards, typically with 150-200,000 miles on it. It’s also a sought-after engine with a price tag to match. We could not find one with less than 200,000 miles for less than $1,500 locally.

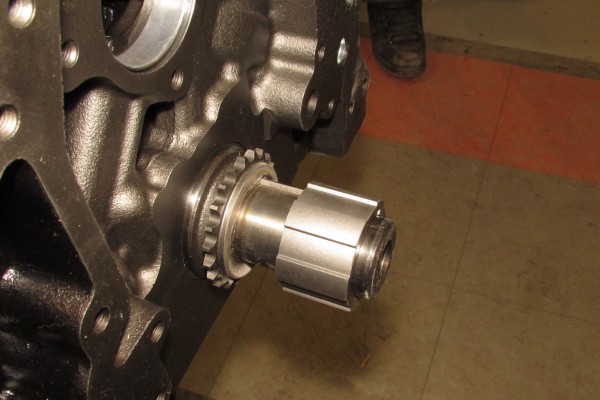

That is when we started looking at rebuilt short blocks. Summit Racing offers an ATK LQ4 6.0L short block for around $2,000. Considering we will be upgrading the heads, cam, intake, and other components, this is about as perfect a deal as we could have hoped for.

Browsing the Summit Racing website for our upgrade parts, we opted for a set of Trick Flow GenX® 220 aluminum cylinder heads. These LS2-style heads feature as-cast 220cc intake runners and CNC-machined 65cc combustion chambers with 2.055 inch intake/1.57 inch exhaust valves. Even with the as-cast runners (Trick Flow calls them Fast As Cast®), the heads flow some impressive numbers. With no porting, the GenX 220s flow 306 cfm at .550 inches of lift. The real story is the mid-lift airflow numbers, which range from 133 cfm at .200 inches of lift to 297 cfm at .500 inches. That beats stock LS2 heads, especially above .200 inches of lift.

Camshaft selection was kept conservative as we were looking for low- and mid-range torque as opposed to top-end horsepower. Our Comp Cams XFI RPM hydraulic roller cam has 212 degrees duration @ .050 inch and .558 inches of valve lift on a 115 degree lobe separation—ideal for our LQ4. We can swap in a bigger cam down the road if so inclined.

Induction is handled by a FAST LSXR composite intake and a 104mm throttle body. We picked up a Holley Performance LS swap oil pan for a Camaro, which will work on our A-body GS with little modification.

One of the biggest lessons we learned from this build is that there are about a bajillion little sensors, special bolts, and covers that you need to complete an LS build. We highly suggest picking up a high-mileage core from a salvage yard if you plan on building your own. The couple of hundred dollars you spend on a core could easily save you a few hundred more in the small parts.

We put the long block together in the Red Dirt Rodz shop. Like most projects, it’s the little parts that get you. Fortunately, Summit Racing carries the bits and pieces needed so you don’t have to scrounge the yards or pay big money at the dealer. Using this article as a guide, you can have those parts in hand before you start building.

How much did it cost all up? What are the power figures? If you had it to do again would you have just refreshed a junkyard engine so you didn’t have to chase parts?

What are the part numbers for the $2000 LS ATK Short block and the Comp Cam used in the build? Can’t seem to find a match anywhere on the Summit website.

When that engine was first started, we used HPE-S19, but we think that is now unavailable. This Blueprint Engines short block is the closest comparable:

https://www.summitracing.com/search/brand/blueprint-engines/part-type/short-block-engines/make/chevrolet/engine-size/6-0l-364/engine-family/chevy-small-block-gen-iii-iv-ls-based-engines

The cam is a CCA-54-424-11.

You mentioned comp push rods in the write up, curious what length and type used?

I dunno about pushrod length and pt.no. but you shouldn’tjust throw pushrods in a build without measuring to get the geometry correct. People do, but that doesn’t make it right. You should get a checking pushrod or two to properly measure your own build. I bought a bunch of different types and lengths from a company that begins with a “C” and offers stainless shaft mount rockers as a specialty. Try the clearance section.

I’m putting an LQ4 in my 05 GTO, with the LS2 in it originally. And I’m so confused on these sensor, and where to find sensor adapters. Where do y’all find those and what y’all do about the knock sensors and oil pressure sensor?