Big cars need big brakes.

While a common drag car might weigh 2,400-2,800 pounds, today’s street-strip machines can easily weigh more than 3,500 pounds. Often these heavy, fast cars tax the rotors, and the thin drag race-only pieces can become cracked or warped due to excess heat. Plus, the small, drag race-style calipers can flex at the mounts because of the heavy load.

The reality is, the latest wave of heavy, fast street machines require something different from typical drag racing brakes. Street-strip cars require the largest possible brake package that can still fit within the confines of a skinny drag race wheel. They also need a vented rotor—something that can dissipate heat on the street and also perform back-to-back runs down the quarter-mile.

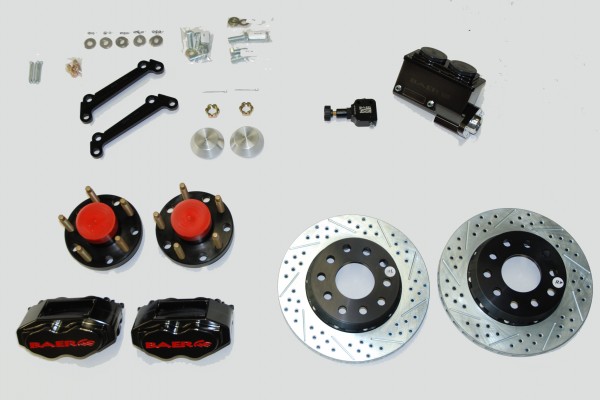

The Baer Deep SS4+ Deep Stage Drag Race Disc Brake kit is the perfect starting point.

Large Directional Vane Brake Rotors

Baer based this kit on its existing SS4+ package, but reworked it with an eye toward drag racing. It includes the largest 11-inch diameter, two-piece rotors that will work with skinny 15-inch wheels. The high silicone cast iron rotors are 1-inch thick and have a directional vane configuration, which cools the brake while rotating. You can have the rotors drilled, slotted, drilled and zinc plated—or all of the above. The rotors are directional (sided to the car), and they have what is called a “reverse slot” or a “reverse slot and drill” pattern. Although it looks “backwards,” it’s actually correct. This setup lowers the potential for “carbon smearing” or transfer from the pad material to the trailing side of the slots on the rotor. Carbon build up on the rotor can translate into shake you can actually feel while braking.

Because Baer’s Deep Stage package is based upon a two-piece rotor, it’s easy to replace the rotors when necessary. Deep Stage rotor hats are machined from 6061-T billet aluminum and then anodized black. The hardware does not directly screw into the aluminum hats; instead, they incorporate ten NAS stainless steel bolts and mechanical lock nuts to affix the rotor to the hat. A step machined into the rotor allows the hat to recess flat, lowering the weight of the iron rotor/aluminum hat configuration without compromising strength.

The package also includes hard anodized 6061-T6-billet aluminum hubs. The hubs come pre-fit and pre-assembled, and the bearings are pre-packed using American-sourced races, bearings, seals (typically Timken or SKF hardware), and synthetic grease. The hubs come double drilled with a 5 on 4.5-inch pattern as well as a 5 on 4.75-inch bolt pattern. The wheel studs are press-in ARP ½-20-inch drag race components with a quick start nose.

With any high performance brake system, the mounting system must be robust. Baer’s Deep Stage bracket is machined from billet aluminum and black anodized. It’s a beefy piece and is held in place by with high-strength bolts. Some kits include a special intermediate bracket that mounts the caliper to the base bracket. The one- and two-piece bracket systems are both engineered to allow for caliper shimming to ensure the caliper is centered atop the rotor. The shims compensate for OEM production line machining tolerances in the factory spindle.

[story continues below slideshow]

Four-Piston Brake Calipers

The Deep Stage kit incorporates heavy-duty four-piston brake calipers. These calipers are physically deeper than many you’ll find on a drag race-only setup, because they include road-going dust seals. They’re sufficiently deep so that they never come in contact with the backside of the brake pad. The seals are square shoulder configurations. By producing the maximum amount of retraction, this type of seal provides the least amount of brake drag and simultaneously eliminates the need for a pair of inline residual pressure valves.

A deeper-than-normal caliper also allows for longer pistons. A longer piston is far less prone to cocking in the bore. When the pads are completely removed, the piston remains in the bore. This is in contrast to many drag race calipers where the piston tends to fall out of the bore when the pad is removed. Each of the pistons is hard-anodized aluminum, and each caliper half is fastened by four 10-mm cross bolts for maximum caliper stiffness.

There are no external fluid lines from each half of the caliper. Typical of OEM calipers, the Baer S4 caliper design accepts a banjo fitting with crush washer on the inlet side. The thread is a 10mm design that is compatible with any number of late model brake hoses. Baer also includes a 10mm to -3AN conversion fitting with the brakes. That means you can use a common Teflon lined AN brake hose.

The brake pads are loaded from the bottom of the caliper. They’re designed so that the pad cannot exit through the top. Baer also incorporates stainless steel abutment plates to eliminate wear on the aluminum caliper body. These plates minimize pad migration as well as excess pad noise.

Each caliper for the Deep Stage series is engineered to a specific rotor thickness. Baer notes they do not use spacers between the caliper halves to make up for a thicker rotor. Typically, the Deep Stage kits are designed for use with 1.-inch thick rotors. The front calipers weigh 4.10 pounds; rear set calipers are slightly lighter at 3.78 pounds.

When it comes time to order a Deep Stage brake kit, you have a lot of caliper options. There are more than a dozen color choices, and Baer can even provide you with a wide range of custom colors. Several of the calipers shown in the accompanying photos are custom colored in “Black Ice”.

Application-Specific Master Cylinder

You’ll also need a quality master cylinder. Baer also has a cool master cylinder named “Remaster.” This is a fully machined, billet aluminum piece that is built specifically for each application. That means you can specify on which side of the master the outlets are located. The Baer Brakes Remaster master cylinder has a short, compact design that fits both power booster and manual brake applications. The 15/16-inch bore option has an overall length of 6.050-inches. It’s just under 5 inches tall to the filler cap and it’s 3 inches wide. One-inch bore Remasters are the same overall size; however, the 1-1/8-inch bore design is slightly larger.

GM and Ford applications can make use of the same master cylinder—the firewall mount is engineered to fit both. For long pushrod applications, Baer also includes a special insert adapter. And Baer designed the master with a removable mount block, which allows you can take the master cylinder with you if you change cars. Also of note: all Baer Remasters have the ability to bolt a proportioning valve block to the bottom of the master cylinder. You don’t need a special bracket to mount the prop valve, plus it simplifies the brake line routing. In addition, if you already have a Baer proportioning valve, then it’s a simple matter of specifying your master cylinder to accept it.

You will need a brake proportioning valve. Keep in mind that most cars we’re addressing have had the original factory distribution and proportioning valves eliminated. These OEM valves were often called “combination valves.” They included a brake pressure warning light sender along with a fixed rear brake proportioning valve. While we don’t have room to go in-depth here, a front disc/rear drum setup will allow too much brake pressure to be applied to the drums without a proportioning valve. Adding taller tires on the rear will also upset the brake balance because the taller tire provides more leverage when you hit the brakes. With these variables on cars, you need a properly adjusted proportioning valve to reduce the brake line pressure to the back wheels.

As you can see below, Baer covers all the pieces you need to safely bring a heavy street-strip car to a grinding halt.

pity they don’t list these for Plymouths