Think all fasteners are created equal?

Of course not. If you’re an engine builder, you know the importance of using good-quality fasteners. And you’re probably also familiar with the torque-to-yield, or TTY, fasteners that have become more common on today’s engines. There’s a big difference between these fasteners and traditional bolts that make torque-to-yield the factory choice for modern platforms like the GM LS series.

For DIYers, though, there’s still a lot of mystery surrounding torque to yield bolts. Because the LS platform is one of the most popular among hot rodders, we thought we’d cover the basics of TTY fasteners and they apply to LS engines.

What is Torque to Yield?

TTY head bolts are common on engines using aluminum heads and/or multi-layer steel head gaskets. While all bolts experience some amount of stretch during torquing, TTY bolts are engineered to stretch within a controlled “yield zone.” Once they reach this zone, they spring back to provide a precise level of clamping force over the entire area of the gasket. This stabilizes the load for a head gasket when the engine is both cold and then as it warms up. This is key with aluminum heads where the expansion rate of the material can stretch typical bolts past their yield point and cause them to snap.

Once the torque-to-yield fasteners are torqued, go through different heat cycles, and are subjected to stretching due to material expansion, they never return to their original length.

For this reason, you should never reuse a TTY head bolt.

This video from Fel-Pro illustrates TTY bolt stretch and why you can’t reuse a torque-to-yield cylinder head bolt.

Which LS Fasteners are TTY?

On a GM LS engine, the cylinder head bolts are TTY and cannot be re-used.

The connecting rod bolts are also TTY, but can be tightened up to three times for bearing checking.

The balancer bolt is also a torque-to-yield fastener.

The intake manifold, rocker arm, and rear cover bolts can be reused.

The vertical main bolts can also be re-used, but the side bolts are often replaced because they have sealant on them. These can be re-used if sealant is re-applied.

How to Install a Torque-to-Yield Fastener

It is important for TTY bolts to reach their controlled yield zone for the most consistent clamping force, so the installation procedure becomes critical. Torque-to-yield bolts require extra steps—and extra care—to achieve proper installation.

To get the TTY bolts into the proper yield zone, you need to tighten them to a certain torque spec, and then turn them an additional number of degrees. You should use a torque-angle gauge to ensure that you turn the bolt the exact, specified amount of degrees. Of course, if you upgrade to aftermarket bolts like ARP bolts, then that torque-angle spec cannot be used since the ARP’s fasteners are made from a much stronger steel. ARP supplies a specific torque to use instead.

When installing TTY-style bolts, follow the proper torque sequence and specifications as follows:

First pass all M11 bolts (1-10) in sequence: 22 ft.-lbs.

Second pass all M11 bolts (1-10) in sequence: 90 degrees.

Final pass all M11 bolts (1-10) (2004 and later blocks): 70 degrees

Final pass all M11 excluding medium bolts (1-8) at front and rear of each head (pre-2004 blocks): 90 degrees

Final pass all M11 medium length bolts (9-10) at front and rear of each head (pre-2004 blocks): 50 degrees

M8 inner bolts (11-15): 22 ft.-lbs.

Before you install the bolts, always clean the threads where the bolts pass through, since any corrosion will create added friction. This can yield a false torque reading and prevent you from reaching optimum clamping force.

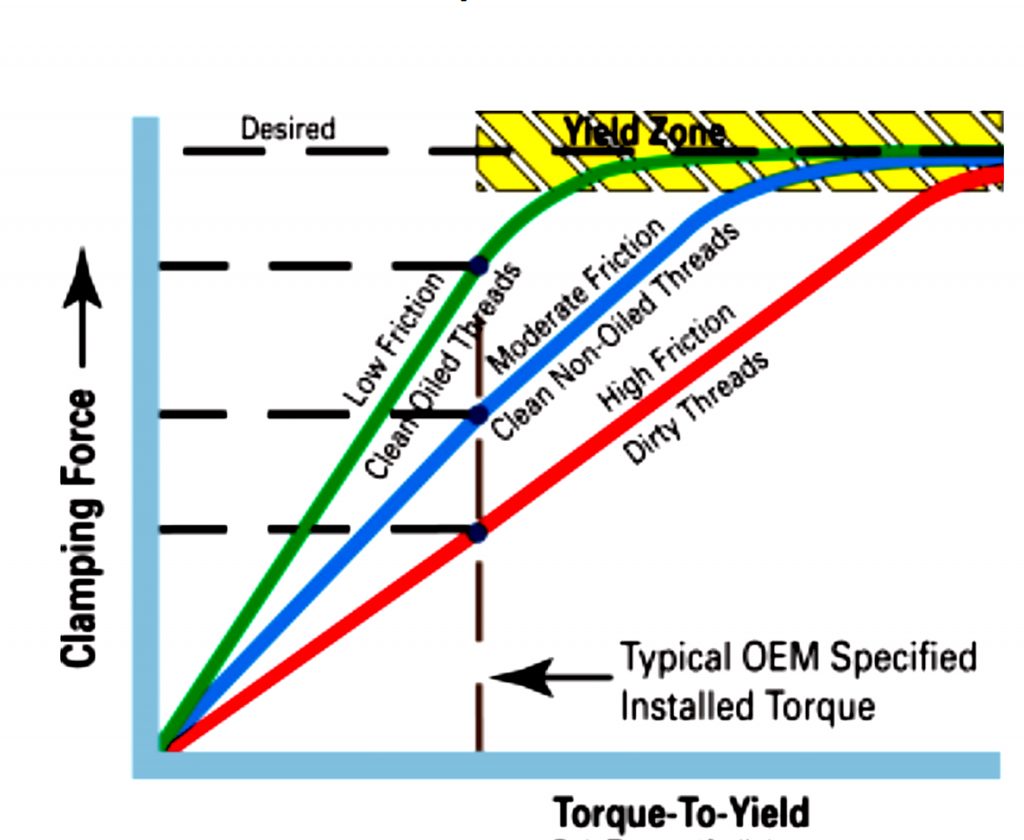

This graph illustrates the importance of reducing friction.

Fel-Pro recommends lightly oiling the threads and under the heads to prevent binding, but warns against over-oiling the bolts.

By following the proper torque specs and sequence and adhering to the tips above, you’ll ensure maximum performance from your TTY bolts.

This article is false. I tried to reuse the main bearing cap bolts and the rod cap bolts and they broke on me.

Chad Long, If they broke then you did something wrong.

LS main cap and connecting rod bolts are not torque-to-yield (TTY) but do use the torque angle (TA) specification.

Where did you get the information that those were tty bolts?

I was just looking for this info for a while. After 6 hours of continuous Googleing, at last I got it in your web site. I wonder what is the lack of Google strategy that don’t rank this kind of informative sites in top of the list. Usually the top web sites are full of garbage.

My understanding is that the LS (In my case LS3). TTY head bolts require no oil on threads or head of the bolt. Can you confirm? This is the first I’m hearing to put oil on the head or threads. The head I could see. But the threads? The factory bolts already have a sealant on them.

Is there room for error on the number of degrees you rotate? I tightened all bolts until they were 22ft/lbs. It took about 3 passes to achieve that goal. Ï then tightened the M11’s an additional 70 degrees. Can I now torque them an additional 90 degrees or should I start over, hopefully re-using the new bolts?

I have a 1998 Buick regal LS is that the engine that you were talking about here? I am scouring the internet trying to find out if I can reuse the rocker arm bolts and a lot of people are telling me I can’t even though the manual says nothing about replacing them with new ones. so can I use them? and would I torque them to the 11-ft pounds then the 90-degree turn that the manual says?

sounds like I cant tell the difference between tty bolts & tta technique(apparently for regular & tty bolts)

I think this is misleading information, and it makes sense that the first commenter broke his bolts.

The video you include shows that the TTY method is torquing the bolts to the point that they’re beginning to yield, which means they are permanently stretched and will not spring back to their original length. If you re-use an already-stretched bolt and apply the factory-spec TTY method a second time, you will be stretching the bolt again, basically doubling the stretch, which will probably take the bolt to or near failure.

No TTY bolt should ever be re-torqued using the original TTY method.

Theoretically, a TTY bolt that’s already stretched could be safely re-used if torqued to a value that would approach the original clamping force without causing the bolt to yield any further. But GM doesn’t provide such a specification (that I’ve seen). It could be determined with some experimentation and spare bolts, but it’s something for a highly-skilled mechanic.

If a bolt, like the GM rod bolts, can be re-torqued to factory spec several times, then they’re not TTY bolts, and shouldn’t be called such. The problem is knowing for sure which bolts are TTY and which aren’t. I haven’t ever seen a definitive source on this question.

The bottom line is that if an engine bolt yields during the factory-spec torque procedure, then the same torque spec should never be used on that bolt a second time. Causing a bolt to yield twice is asking for failure. A stretched bolt can only be used again safely if the torque procedure is modified to stop short of a second yielding.