Debuting at the 2014 SEMA Show, United Pacific’s Company Coupe is as fresh as the day it rolled out of Roy Brizio’s shop. The ’32 five-window was built for Major Lin, founder of United Pacific and a fanatic for all things early Ford. (Image/United Pacific)

Roy Brizio has built a deuce coupe or two in his time. So when hot rod parts manufacturer United Pacific wanted to build a ’32 five-window using the company’s all-steel body and other components, Brizio Street Rods was the obvious choice.

Based on a concept by Thom Taylor, the ’32—dubbed the Company Coupe—is the fifth car built by Brizio using a United Pacific body. The first was the Edelbrock 75th Anniversary coupe, built in 2013 using the very first body out of the stamping press.

“We’ve built three highboys and one full-fendered car using United Pacific bodies,” Brizio said. “We’ve had people stand back and take a good look to see if they could tell if they had original Ford bodies, and most couldn’t. The quality of the United Pacific bodies is outstanding, and with finding original cars becoming more and more difficult, these bodies make our job so much easier.”

Built for display at the 2014 SEMA Show, the 1932 Ford Company Coupe is based on body shell Number 32. Officially licensed by Ford Motor Co., the body’s panels are stamped out of 18-gauge steel on hand-built, permanent steel dies to duplicate every detail of Henry Ford’s original.

The body is TIG-welded on a dedicated jig in a process that takes about 12 hours. The body has a stock height roof and comes assembled with the hardwood inner structure, doors with latches, and a trunk-style hinged deck lid. It’s the real deal—check out this Rod Authority article on the development of the UP body.

Ford built just 56,000 five window coupes in 1932, but it built a whopping 200,000 trucks. United Pacific is now making steel cabs and other body parts to restore a ’32 truck or to use as the base for a rod build. The truck components are made to the same exact OEM specifications as United Pacific’s coupe parts and are also licensed by Ford. (Image/United Pacific)

The coupe’s foundation is a custom frame from Pomona, CA-based Walden Speed Shop.

It has a buggy spring front suspension with a Super Bell four-inch drop I-beam axle and Pete & Jakes hairpin radius rods, spindles, and tubular shocks. Out back is a 3.70-geared Currie Enterprises Ford nine-inch axle with a Pete & Jakes four-link/buggy spring suspension. The brakes are Wilwood four-wheel disc brakes. The shiny chrome was done by Sherm’s Custom Plating in Sacramento, CA.

The drivetrain is pretty cool too—an Edelbrock Performer RPM 347 Ford crate engine upgraded with throttle body EFI and backed by a Bowler Transmission 700R-4 four-speed automatic.

The body, suspension, and drivetrain were trial-fitted at Brizio’s Street Rods before the car was disassembled and sent out for body prep and paint. Bill Ganahl at South City Rod & Custom in Hayward, CA chopped the roof two inches and prepped the body for paint. The body and frame were sprayed House of Kolor Pacific Blue by Joe Compani at Compani Color, also in Hayward.

Final assembly was done at Brizio’s shop.

Other parts used in the Company Coupe build include:

- Custom exhaust system by Flowmaster

- Flaming River steering box, linkage, and column

- Vintage Air climate control

- Classic Instruments gauges

- 16-inch Coker hotrod steel wheels and Excelsior radial tires

- Dan Fink grille shell and insert

United Pacific provided photos of the Company Coupe build, which you can see here:

Body Number 32 sitting on the Waldan’s Speed Shop frame at Brizio’s Street Rods. Officially licensed by Ford Motor Company, the body’s panels are stamped out of 18 gauge steel on hand-built, permanent steel dies to duplicate every detail of Henry’s original. The body is bucked in a dedicated fixture, then riveted and spot-welded just like the factory did 85 years ago. Another 12 hours are devoted to TIG-welding the seams, and another day or so doing final assembly. The body has a stock height roof and comes assembled with the hardwood inner structure, doors with latches, and a trunk-style hinged deck lid. All of the body components are available separately for folks restoring or rodding an original ’32. (Image/United Pacific)

…

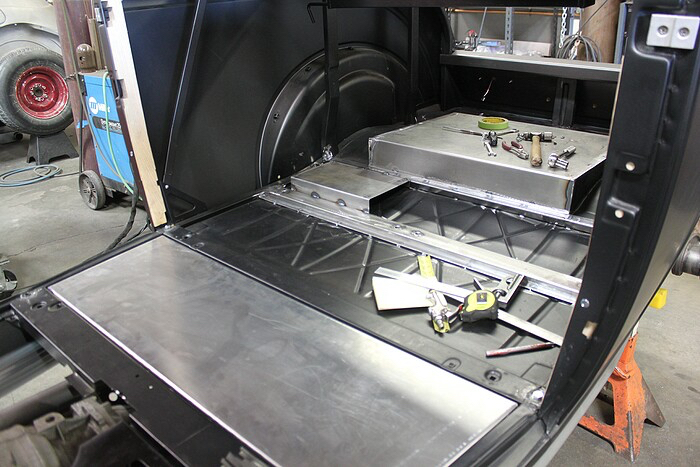

Some of the floor was made from 16-gauge steel to accommodate the 700R-4 transmission, the pumpkin of the Currie Enterprises 9-inch rear axle, and the custom bench seat. (Image/United Pacific)

…

The drivetrain, exhaust system, and suspension components mocked up on the frame. Note the Wilwood master cylinder sitting in the stock underfloor location, and the transmission cooler mounted on the passenger side frame rail. The driveshaft from Driveline Service is only 29.75 inches long yoke to yoke. That’s thanks to the big GM 700R-4 transmission, set up with an adapter plate to fit the Edelbrock 347 Ford crate engine. (Image/United Pacific)

…

The body was also assembled on the chassis to check for proper fitment and make any adjustments before blowing everything apart for painting. The United Pacific body shell comes with a rust-resistant EDP coating, which will be removed during body prep at the paint shop. (Image/United Pacific)

…

Back from body and paint. Bill Ganahl at South City Rod & Custom in Hayward, CA chopped the roof two inches and prepped the body for paint. The body and frame were sprayed House of Kolor Pacific Blue by Joe Compani of Compani Color, also in Haywood. Pacific Blue is a Ford Washington Blue tinted a half-shade lighter with some pearl mixed in. Brizio’s Street Rods handled the final assembly. (Image/United Pacific)

…

This photo gives you a good look at the Edelbrock 347 cubic inch Ford crate engine. Based on a Ford Racing Boss 347 short block assembly, the engine gets a set of Edelbrock Performer RPM aluminum cylinder heads, a hydraulic roller camshaft, a Performer RPM Air Gap intake manifold with a Thunder AVS carburetor, oil pan, distributor, valve covers, water pump, and harmonic damper. The carburetor was swapped for throttle body EFI. The front accessory drive is from Vintage Air. (Image/United Pacific)

…

This shot gives you a great look at the United Pacific body’s wood substructure. It’s all solid ash hardwood with the mounting holes drilled in the factory locations. Even the mounting screws are recessed exactly as Ford did it. A generous layer of Dynamat sound and heat insulation was added make the car more comfortable to drive. (Image/United Pacific)

…

Legendary interior stitcher Sid Chavez did the Company Coupe’s door panels and seat in Oxblood Red leather with matching carpet. Classic Instruments supplied the gauges, the shifter is from Lokar, and the steering column is a Flaming River unit. (Image/United Pacific)

…

One United Pacific five-window coupe, ready for wheels, tires, and a driver. (Image/United Pacific)

…

The underside of the ’32 is just as nice as topside. Anything chromed or polished was done by Sherm’s Custom Plating in Sacramento, CA.

…

One more look at the finished vehicle. (Image/United Pacific)

Do you sell these kits? Can’t find on website.

Do you have a link to buy these kits?