I recently bought a FiTech Go EFI fuel injection system for my big-block Chevelle. The engine is a 468ci big-block with a mild hydraulic roller cam, a TH400, a warmed-over converter, and 3.55:1 gears in the 12-bolt. I used to run an 850 Holley. It ran great but always was rich. We installed the system and it runs pretty good except that the engine idles too fast, like 1,025 rpm instead of the 850 rpm we put in. We tried lowering the idle rpm on the hand-held but it really didn’t do much and it should idle where we tell it to, right? Can you help?

B.L.

Jeff Smith: We’ve seen this issue on several self-learning throttle body EFI systems and from what we’re reading on many of the forums, this is a common problem. The good news is there is an easy fix. If you’ve been reading my column for any length of time, you know that we always start with the basics, so here goes…

Before we even get into how to tune the idle speed correctly, we have to also first look at the mechanical side of the engine to make sure there are no vacuum leaks. An engine with a vacuum leak can run at a higher than commanded idle speed and will tend to idle erratically. So make sure all of the intake manifold and throttle body bolts are tight and there is no uncovered vacuum port. It might also be worthwhile to spray a little brake clean or carburetor cleaner around the intake with the engine idling as a test for vacuum leaks. This is a very common problem and any leak must be eliminated before proper idle speed tuning can be accomplished.

When any of the EFI companies build a product like a self-learning TBI system, they are forced to design it to accommodate an incredibly broad range of engine sizes and combinations. Your Go EFI FiTech is designed to control fuel for engines that make up to 600 horsepower. That’s a bunch of power but it also could be called upon to control a very mild engine. This is where the variables begin to stack up. Typically, a large displacement engine will demand more air than a small displacement engine. It’s also important that the engine start and run the first time you turn the key. So the EFI companies dial in a tune that is guaranteed (assuming you set all the initial inputs properly) to run the first time.

Now let’s talk about one of the crucial systems on any EFI system: the idle air control (IAC) motor. This is a small stepper motor that controls the amount of air that is by-passed around the throttle blades. This is done to control idle speed electronically. With a carburetor, if you need more idle speed you just turn the curb idle screw clockwise and this opens the throttle blades to allow more air into the engine. That’s simple and very effective.

But an EFI system also must be able to control the idle speed with different load dumps like dropping the engine into gear with an automatic or when you switch on the air conditioning compressor. An EFI system controls idle speed by using a combination of the air allowed past the mechanical curb idle setting combined with a measured amount of air bypassed by the IAC. The ideal combination is where the throttle blades flow a majority of the idle air with a small contribution from the IAC motor setting.

The ECU establishes the final commanded idle speed by opening or closing the bypass air using the IAC motor. The amount of bypassed air is determined by a tapered cone positioned by the IAC motor. It operates by turning a screw that positions the tapered cone. These are sometimes referred to as steps and one complete revolution of the screw is referred to as one step. The ECU then uses rpm feedback to position the IAC.

If the engine idle speed needs to increase, the IAC will open a few steps, allowing more air into the engine. Or, the IAC motor will move close to fully closed if the idle speed is too high. With any aftermarket EFI throttle body system, the first thing that must be done is to ensure that the throttle position sensor (TPS) actually reads 0 with the throttle at curb idle. Other EFI systems require you to perform certain steps to make this happen, but the FiTech does this electronically. So if you change the position of the throttle plates with the curb idle screw, all you have to do is cycle the key off – wait a few seconds for the numbers on the display to disappear from the screen and then turn the key back on and the TPS will reset to zero.

Now that we know how this system operates, you may be able to see how some engines might not experience accurate idle speeds given that the factory must establish a given position and that may not be perfect for all engines. So with a big block Chevy that idles too fast, the solution is to follow a simple procedure. This should only be attempted with the engine at normal operating temperature – which for the FiTech is above 160 degrees F.

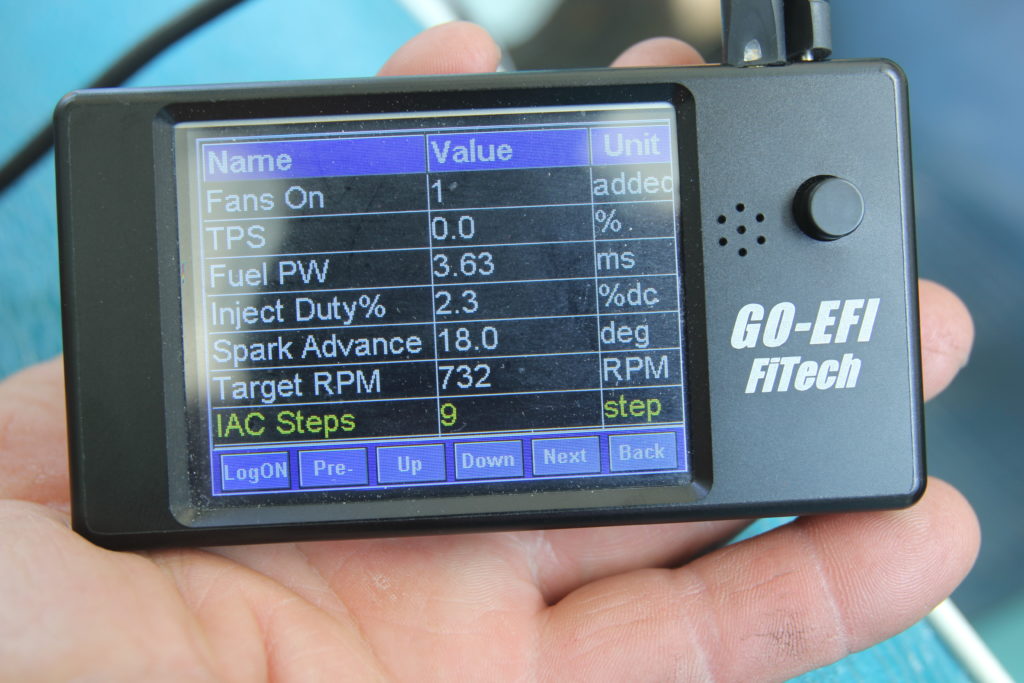

The first step is to ensure the TPS reads 0 with the key on and engine idling. The TPS position is found on the dashboard screen. With that established, we need to find what FiTech calls IAC steps. This can also be found on the main dashboard by scrolling down roughly about a third of the way. With the engine idling, monitor both the IAC steps and idle speed. In the case of this big block Chevy, it appears that the throttle blades are open too far which means the IAC steps will be a very low number – perhaps 0. In order to reduce the engine speed, the first thing we need to do is to close the curb idle position of the butterflies. Do this by slightly by turning the primary idle speed screw out (counter-clockwise) about a half turn. This should slow the engine down. Then shut the engine off long enough for the TPS to reset. Restarting the engine should reveal an increase in the IAC steps to perhaps around 8-10. If the IAC steps are more than this, you will need to turn the curb idle speed screw in slightly and then repeat the shut-down procedure.

This is the dashboard screen on the FiTech that indicates the IAC steps that will help you dial in the idle speed on the system. It may seem a hassle but it’s not difficult, but it can require 10 or 15 minutes of effort to get it dialed in properly.

Conversely, for example, if your engine idles at close to your commanded rpm but the IAC steps are higher than the preferred 3-10 steps and instead are up around 25 to 50 steps or higher, this would indicate the curb idle position of the throttle blades is not open enough, not allowing sufficient air in and forcing the IAC to open a greater amount than desired. You might notice this as a gushing or a noisy air inlet sound coming from the top of the throttle body. This noise is a large amount of air being bypassed by the IAC. This reduces the total authority of IAC movement which could affect drivability, so it’s best to open the throttle blades by a half-turn clockwise, shut down the engine, allow the numbers on the handheld to go blank and then restart the engine. If this change achieves IAC steps at idle of between 3 and 10 then you’re where you need to be.

All this should only take a few minutes to establish, but these small efforts pay off with enormous benefits. Notice that the idea is to make very small changes — never more than a half-turn on the idle speed screw. These small changes will make it easier to sneak up on the proper position for the throttle blades and the IAC steps.

We’ve done some around-town driving experiments in L.A. traffic and depending upon where you live and how you drive, it’s entirely possible that your engine spends 70 percent or more of its time at idle. So spending some quality time dialing in a repeatable and stable idle adjustment is really very important. And your friends will think you’re a tuning genius!

I would love to see the same subject on a dual quad EFI system from FAST. I cannot get the idle to settle in without the butterflies completely closed which results in my manually opening them with the gas pedal to get the car to start. Idle is 800 with them completely shut and 2,200 with them cracked open just a hair to get the car to start. I reset the TPS once I crack them open or close them.

there are two idle screws one on the front left and one on the back right it should be the same on a dual quad set up. have you messed with them?

This is the exact problem I am having. I do not remember posting this but if it was me I am hoping you are still on this site. Here I am 3 years later still having problems. The IAC motor was replaced as was the manifold and throttle body gaskets trying to eliminate all vacuum leaks. The factory throttle body gaskets were the biggest problem. However, I still have the butterflies closed at start up and the IAC count is zero. It idles at 900 but takes a longtime to get down to that number after releasing throttle. I basically have no downward IAC adjustment which could be the issue. At a loss….

I had the same issue for a year,came across something on the web about the map sensor rubber seal/bushing that sits behind the front cover of the fitech unit, near the bottom behind the cover, after removing the 4 allen head screws take the little seal out and cut the bottom of it off leaving about 1/16 inch,you will only cut about 1/8 inch off, put the seal back on the map nipple and reinstall.fixed my problem completely,no more high idle, I say its a defect, the seal either blocks the map from getting a good signal or it leaks air into the t body, hope it helps, worked for me no more headackes and I can finally tune this thing

fi tech actually has a “idle set mode” u can play all day & will never get the idle correct till u go to the idle set mode & adjust idle as they tell you how to. You can also turn down/up the time for idle to go to base after cruise etc… good article, vacuum leaks etc, id rather see a “smoke machine” used than carb, brake cleaner to locate leak, who knows what those chemicals do to the 02 sensor. contact fi-tech for a instruction sheet on “idle mode setting”, they e-mailed me fuel curves(accelerator pump) adjustments etc… good people to work with.

Great article. In my experience we use carb cleaner or wd40 for carburetors and listening for rpm changes. With EFI that has not seemed to work the same way as the EFI “masks” smaller leaks (does not fix) since the system uses the O2 sensor to essentially correct for the additional air intake.

Although I have not used one the smoke machine may be a better option.

I suspect you can still leverage the carb or wd40 but you need to monitor the EFIs effort in correcting for the changes you introduced. If you spray the EFI base and the IAC counts jump then you need to stop… let it recover and try it again. If it is reproducible then you found a leak.

I’m installing a FItech 600HP system , with a MSD-6AL box and the 2 wire MSD distributor (locked) and Blaster 2 coil.. the issue I’m have is the white wire from the MSD box should be the trigger wire and on the instructions it clearly says to connect to the black (coil) wire from the FItech harness.. but it just cranks but no start .. what am I doing wrong ? This is giving me a headache for sure

The with wire is when you are using the points to trigger the MSD spark box. You have a two wire MSD trigger dist so thats your input to the MSD box. You need to use the Grey wire (0 – 5 v square wave) from the MSD box as your trigger to your efi controller/rev counter or the rev counter outlet on the front of the MSD box if you have no grey wire.

i have the mean street 400 on a 350 h.o. deluxe motor and idle fluxuates 400 rpm +/_, but if i plug intake bypass hole on top with my finger it runs perfectly .why ?

I had this issue on my 351w. The engine was firing and running but at an extremely high idle. I followed all of the trouble shooting tips and experience from fi-tech. After confirming there was no vacuum leak and the voltage was correct. I also checked fuel pressure and could not figure out why the engine was idling so high even after adjusting the throttle control screw. What ended up fixing the issue was the easiest solution. I simply reset the handheld device by going to write cal and set up the engine specs again. After doing this the adjustments to the throttle adjustment started working. Hope this helps someone with the same issue.

Hi I’m new to the forum I have the fitech 600 hp model my mechanic installed this for me and I’m afraid he may have mad a mistake. First big one is when I turn off ignition the controll box stays on. Based on what I’ve read I’ll never get anything to reset if I can’t shut the controller off. True or false

Chris

If you mean by “ignition control box” that after you turn off the key the Fitech display stays on this is normal. When the key is shut off this play will stay on for approximately 15-20 seconds and then it will go black. The fitech has to power wires, one heavier red wire that will stay hot all the time and a second smaller red wire that is supposed to be connected to something that goes hot when the ignition switch is turned on. The second smaller wire is what tells the fitech to shut down when you turn the key off.

I have your 600hp throttle body installed with your 340 in the tank pump and return line. Do I need to use the pulse width modulation or turn it off. If so what input number do I use. Not much info about this in the instructions.

I have a 383 stroker with the 600 hp fitech. I have adjusted the IAC over 25 different times and the best I can get it is where it bounces between 0 and 4, back and forth. If I turn it to get off 0 more towards 3 or 4 it will go up over 25 on the next start up. I have yet to see a stable number and the motor Never starts on first try. I have added fuel to all start temps and it still needs a pump on pedal to get going. I am not sure where I have gone wrong but am thinking I need to start completely over. However the motor runs great while driving and idles at 850 rpm. ( but smells rich even though the afr reads 13.6 at idle. )

I have a 383 striker I just installed and put the 600 hp fitech on it. I’m having similar problems as you are. Mine normally cranks in the first try, but every time I set my IAC between 3-10 the next day it changes. It runs great when I set it, but it just keeps changing. Have you figured out the problem with yours?

Thanks!

I have a 600hp my problem is it is dumping gas so bad black smoking fouling plugs

I can not get the IAC steps between 0 and 10 without the TPS going to .5..

This is my experience as well, 2 years later!

We have the 600 hp fitech with command center.we set the tps to 0 and the iac at 2to 4. The problem we have is hard cold start with a little ruff idle have to help get started with gas pedal.when warm the car idles good and performance is good.what do we need to do to get it to start when cold.have a mild cam Yorker intake and shorty headers.thanks greg

66 Chevelle

74 bbc 454, 68 Vette 396 heads with mild street cam and tr6060 6-spd. Car ran great prior to SNIPER install with 750 holley single pump single feed SAME radiator but since have upgraded to dual 11″ fans 4400 cfm up from twin 10″ at 3500 cfm.

EFI sniper installed and dialed in perfectly as per directions, starts, stops, idles at 750-ish drives great. Zero cold or hot start issues, no backfires or miss, accelerates and decelerates perfect up and down through the gears.

Problem, when at idle temps creep up to 207 but while driving recovers to 195 in 85 to 100 deg Cali weather without A/C load.

Radiator is triple by pass dual core aluminum with twin 11″ Derale fans in shroud pulling 4400 cfm. New OEM water pump has been installed as well.

Could this be a lean at idle condition?

If so how to fix?

30003 system on 351w after engine gets to 170 temp won’t ideal. It goes up and down and dies. Put in gear it will die. The IAC is at 5. If temp is at 120 it runs good. After it warms up it won’t run. Ideas

I set my IAC multiple times now in the past week, but every time I drive my truck the IAC ends up being different at idle. Why does it keep changing and how can I stop it from changing? I assume that once it’s dialed in it should stay that way.

Thanks for your help in advance!

Chad

I put an extra return spring on mine bcuz I noticed if i put a little finger pressure on the throttle to close it the iac and tps would change, after the aditional spring it pulled it closed all the time and i was able to stabilize the idle the way it should be and set the iac properly, mine was changing daily also

I can’t get the Fitech injection to idle smoothly. The rpms constantly fluctuates between 850-1150 rpms. I have adjusted the IAC as best as possible. But rpms fluctuate too much.

Jeff i bought the 750 ls ultimate intake. The engine runs great but the 4l60e is not shifting out of 1st?

I loved your comments. I am looking for the Delco temperature sensor you recommended to replace the FitTech temp sensor. Can you send my that number.

Thank You

Stay Safe

I have a FiTech Go Street 400 on a SBC 350 create motor.

I am having a problem with the fan control. I set it at 188 on 180 off. When the handheld shows 188 the fan show that it is on but it is not when the engine cools down below 180 the hand held shows that the fan is off. I disabled the fan control and connected the fan to my old sender using the same ground circuit to the fan relay and the fan turns on. The fan did work with the FiTech enabled at first but will not work now.

Another thing is the black wire for the air conditioning idle speed kickup. Were do you connect this wire and will it see 12 volts or should it see a ground? FiTech told me to connect to the air condition clutch ciruit but the instruction with the FiTech said connect to ground. Which one is correct?

I have 400 Pontiac and put the efi on there couple years ago.it always had that whistle noise. though it was breather was sealed tight. then read about the iac. so went through the steps and got it where it post be. car didnt whistle and sounded good. I go drive it get down road it dies on me and couldnt get it back started. so turned screw back to where it was but not still wont start now. do u no y this would be.

1979 C-10WITH THE 70001 UNIT ON A 5.3LS

i CAN ONLY GET THE iac STEPS DOWN TO ABOUT 32-35

ENGINE RUNS FINE REFGARDLESS OF THE iac STEPS .

But if I turn off my engine after adjusting the steps let the truck sit for an hour as soon as I restart it the steps reveret back to 100-120