If you are a mall crawler—a Jeeper who never takes your Jeep to the rocks, wash-outs, and shale hills that make for exciting wheeling; you needn’t read further. Your Jeep’s steering and suspension systems are more than stout enough to last for as long as you own the Jeep.

However, if you’re more like me—and use your Jeep on adventures for which it was designed—read on.

The components discussed in this article are available for all TJ/LJ/JK model Jeep Wranglers; just slightly modified with different part numbers for the various models. However, the installation procedures will be similar for all.

To paraphrase the old motorcycle rider’s axiom, there are two kinds of Jeep drivers:

- Those who have experienced death wobble, and

- Those who will experience death wobble.

Well, if your Jeep has leaf springs, you probably won’t. It only seems to affect those with coil spring and control arm suspensions. In order to avoid death wobble, you must first do a great job of maintaining the steering and suspension system. Keep everything well-greased and tight.

Before we get into the changes we made to stabilize our steering, let’s mention that this Jeep—a 2005 Wrangler Unlimited Rubicon—is equipped with a TNT Customs long-arm four-inch lift kit with ARB springs and Fox Shox off-road shocks. This is one of the best hardware kits I’ve ever worked with. Its axle trusses, which are used for control arm connections to the differentials, greatly strengthen the stock Dana 44 differentials, but must be precisely located.

Steering Tie Rod and Drag Link Kit

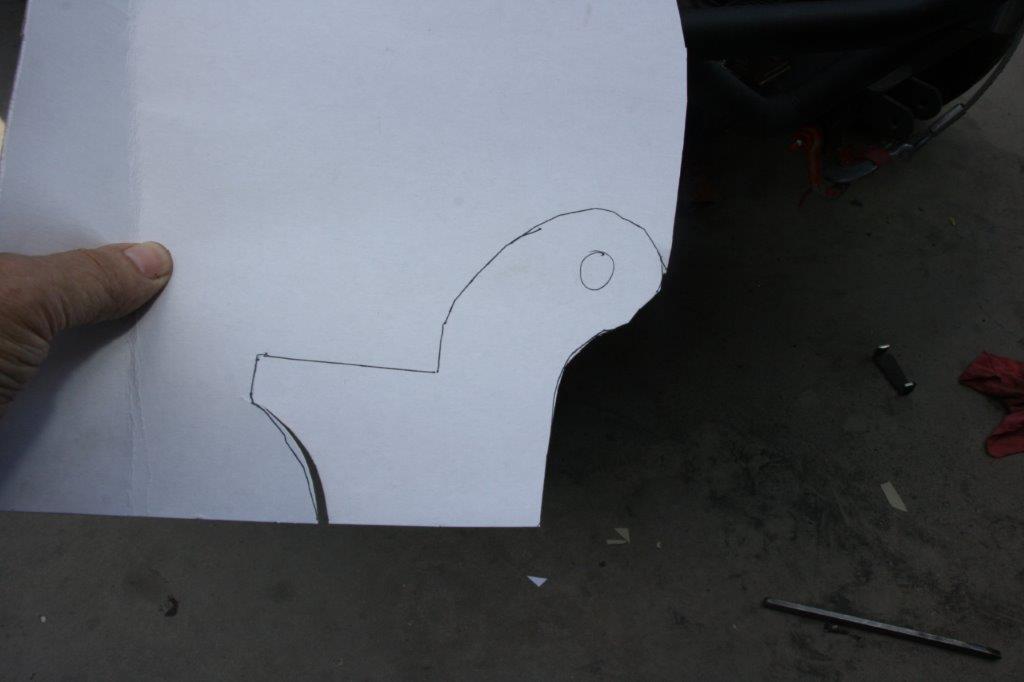

Now, with the TNT long-arm kit installed, the first thing we needed to do was strengthen the Jeep’s steering.

We discarded the OEM drag link and tie rod for a new assembly from Rugged Ridge—the Tie Rod and Drag Link Kit. According to Rugged Ridge: “This is a bolt-on solution for preventing bent tie rods from wheeling with larger tires; the tubes are 1-1/4 inch OD steel that is cold rolled, pierced, and drawn through dies to produce a ¼-inch wall thickness. This is true DOM tubing with no seams or welds to fail. Heavy-duty 7/8-inch rod ends feature standard tapered ends to fit stock knuckle applications. You get one ton strength without any modifications to your steering knuckles. Not recommended for vehicles with over four inches of lift. Not compatible with smaller OEM steel wheels or wheels with deep backspacing. Not recommended for vehicles with under two inches of suspension lift.”

Bump Stops

Once we had the steering under control, we wanted to add more “oomph” to the suspension so dirt roads could be handled at higher speeds without damaging any components. The TeraFlex TJ SpeedBump bump stops are a composite system designed for high-performance Wrangler applications. Bump stops reduce suspension compressing impacts and the associated harsh bottoming out. This action reduces the risk of bending an axle housing and increases the ability to maintain vehicle control. The company says, “TeraFlex SpeedBumps feature performance tuned closed-cell nitrogen charged microcellular polyurethane technology, providing a true progressive bump stop that will not fade or dissipate under extended heavy use. Microcellular polyurethane technology is not affected by temperature extremes, and retains thermal and sub-zero temperature flexibility. The Delrin acetal resin polymer shaft is self-lubricating to allow thousands of continuous cycles without wear or abrasion.”

So, with the SpeedBumps in place, the suspension works in this manner. The Fox shock absorbers control compression and rebound over the light-duty surfaces where the springs don’t compress all that much. When things get frisky and the springs begin compression more, the SpeedBumps come to the assistance of the Fox shocks. The coupling of the bump stops with shocks keep both bump stops and shocks from working as hard as they would singly, therefore producing less heat in each, extending the life and control of each component. A side benefit of adding the bump stop’s mounts raised the Jeep at least another inch (we weren’t expecting that so we didn’t measure before and after).

Sway Bar

The piece d’ resistance that ties everything together is the Currie Antirock sway bar. These kits provide the balanced performance of front and rear suspension for rugged off-road conditions. They give the driver increased traction by balancing and distributing the weight among all four tires. They’re made of SAE 4130 heat-treated steel for ultimate strength. Unlike factory sway bars, Currie Antirock sway bars need not be disconnected when off road for more articulation. And like the OEM sway bars, they greatly reduce lean on highway curves and corners. On those narrow, slippery, off-camber trails, the Curry Antirock sway bars steady both your Jeep, and your nerves.

Check Your Shocks

One last thing, make sure your shock absorbers are doing their job. In the old days, we’d simply push a car’s bumper down sharply and allow it to rebound quickly. If it steadied with just the one rebound, the shocks were good. With your Jeep’s shocks being much better designed and much stronger, a little more work is involved testing them.

It’s not very scientific but it seems to work. Using a floor jack, lift the Jeep with one differential at a time to where the tires are six to eight inches off the ground. Release the floor jack quickly and completely so that the Jeep bounces on the ground. If, like the car above, the Jeep only bounces once, that differential’s shocks are good. Do this at both ends, and then visually inspect all four shocks carefully. Make sure they don’t scrape or contact any surface during their movements. Make sure they are not leaking (look for oily residue or dirt collecting on oil). Lastly, make sure their mounting bolts are tight and meet their torque specs.

Interesting