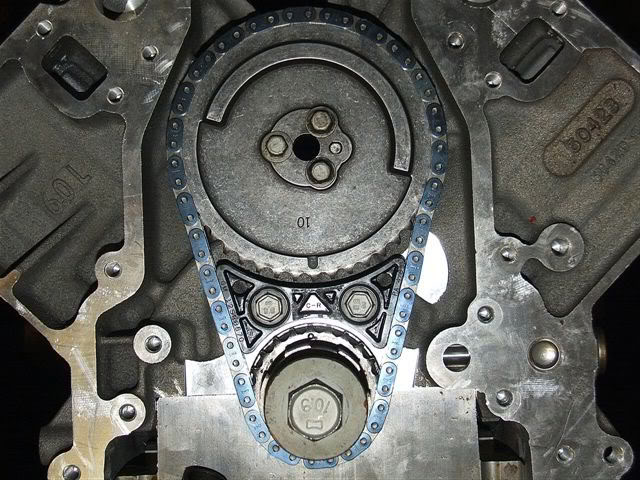

(Image/Corvette Forum)

I’m building an iron 6.0L LS engine and just tried installing the timing set and the chain is super loose. I wasn’t sure how old this timing set was so I bought a brand new chain and it’s just as bad as the original. The machine shop align honed the block but I didn’t think they took that much off the block to make that much of a difference. Is there just a shorter chain I can buy to tighten this up? Thanks.

T.M.

Jeff Smith: I called my local machine shop—Jim Grubbs Motorsports in Valencia, CA—and asked their resident block machinist Ryan Peart about align-honing blocks. He told us that he only removes the absolute minimum needed to bring all the main bores into compliance.

He said a typical average for most street engines is to remove about 0.002 to 0.003 inch from the main cap and then he hones the housing bore back into the middle range of the spec. Remember that removing a total of 0.003 inch from the cap is equivalent to a total change in diameter of 0.0015 inch from the radius which also represents the center-to-center distance between the crankshaft and the cam.

Your description makes it sound like whoever machined your block took much more than just 0.002 to 0.003 inch off the caps for this to occur.

We did some research and it appears Cloyes has what you are looking for.

The best way to approach ordering a shorter chain would be to first measure the center distance (CD) between the centerlines of the crank and cam.

Cloyes offers a procedure to do this since accurately finding the center on the crank and cam can be difficult.

Cloyes’ procedure is to measure the overall distance from the top of the cam gear to the bottom of the crank gear. Cloyes calls this metric “Measure Over Shaft” (MOS).

Next, you measure the diameter of the crank gear and cam gear, and then divide them by two and add them together.

Finally, you subtract that number from the MOS.

We made up some numbers to illustrate the math. The overall MOS is 9.295 inches. The equation for this hypothetical scenario would look like this:

CD = MOS – [(Crank Gear / 2) + (Cam Gear / 2)]

CD = 9.295 – [(5.680 / 2) + (3.140 / 2)]

CD = 9.295 – (2.84 + 1.57)

CD = 9.295 – 4.41

CD = 4.885

The stock center distance for an LS engine is 4.890 inch and our number of 4.885-inch center distance reveals a package that is a 0.005-inch shorter distance, which would create slack in the chain.

Cloyes offers its high performance dual roller timing sets with standard or either a 0.005-inch or a 0.010-inch shorter chain. Using the above example, it appears that a 0.005-inch shorter chain would probably be best.

Unfortunately, we didn’t find any source for a slightly shorter stock chain, so you will have to invest in the more robust Cloyes dual roller system for the LS 3-bolt camshaft. We will assume this is an early iron 6.0L block that is the 24x reluctor package that places the cam sensor at the back of the block.

Here are the part numbers for a standard length dual roller timing set as well as both a 0.005-inch and a 0.010-inch longer chain set from Cloyes.

Description |

PN |

Source |

Price* |

| Cloyes Double Roller Timing Set | 9-3659X3 | Summit Racing | $161.99 |

| Cloyes Double Roller Timing Set, 0.005” | 9-3659X3-5 | Summit Racing | $161.99 |

| Cloyes Double Roller Timing Set, 0.010” | 9-3659X3-10 | Summit Racing | $172.97 |

(*- prices as of November 2017)

Keep in mind that a dual roller chain will put the crank gear up against the oil pump—but Cloyes supplies a nice spacer to move the pump outboard. This will also require you to carefully grind out the mounting bolt for the oil pump pickup since it will now not be in the right place to bolt to the engine. A small thing, but necessary.

This should put you back on the road with a tight timing set, but you might consider looking for a new machine shop as it seems that quite a bit of material was removed from the caps to align-hone your block. We have to assume this since we don’t know the engine’s prior history, but with an iron LS block, these blocks are very durable and rarely would be subject to that much movement unless the engine really burned up the bearings.

This article does not make sense. Just line honing the main bearing bores should not create a condition which results in the center line of the crank being relocated, unless someone is deliberately trying to relocate it. If material is removed in the honing process, causing the bearing bores to be larger, oversize bearings are supposed to be used to compensate for the larger bearing bores. Using the correct oversize bearing inserts puts the center of the crank right back in the center where its supposed to be which allows the factory timing chain length to still work correctly. Oversized bearings are used to compensate for removed material and increased bearing bore diameter after line honing the mains in the block. Not to be confused with undersized bearings which are used for undersized crankshaft journals after a crank has been turned on a lathe and the journals were reduced in size. Replacement bearing inserts can be purchased which are both over and under sized.

Ken, I am not a machinist, but I see your point here and I think that it is preferable as it does not disturb the other engine measurements. This would not move the centerline of the crank, whereas movement of the centerline does occur if you take a few thousands off the main caps and then re-hone the block and installed caps to size as this requires that the hone touch the block surface of the bore a bit. I believe that the latter was done here with T.M. and thus his issue.

Ken,

I have to disagree with your statement. There are oversize main bearings available, but these only address the clearance relative to the main shaft diameter. What we are discussing here is a process where the machinist will align bore the mains. The way this is accomplished is by first removing material from the flat portion of the main cap where it contacts the engine block. By removing a few thousandths of an inch from the flat portion, this makes the inside diameter of the housing bore smaller. Then the housing bore is either bored or more often align honed back to its original inside diameter and also aligning all the bores so that crankshaft will turn easily.

I have personally measured a 5.3L LS truck engine that had probably been overheated (it failed two rod bearings, which is why it was apart). I measured a MINIMUM of 0.0035-inch in three of the center main bearings that were low compared to the outboard webs. So that means the machinist would probably have to take more than that out of the radius just to align all five inside diameters. This is certainly more than usual but clearly it has happened. When the block is machined and material is removed – that moves the center line of the crankshaft main bearing housing bores closer to the cam centerline, which reduces the distance. Simple as that. An “oversize” bearing has no impact on the distance between the crank and the cam.

Again, bearing inserts for a given engine are based on their inside diameter – not the outside diameter. I think that may be where the confusion lies. Yes, there are main bearing inserts or “spacer” bearings that change the O.D – but they still do not affect the crank centerline. I know of no bearings that alters the crank centerline.

Jeff I missed the part in the original article about removing material from the flat part of the caps. That would definitely throw the center line off. Thanks

Smith and Cloyes are correct in the measurement method, however, how many folks have the engine out the car, on a stand, and possess a set of measuring tools and micrometers to measure within 3 thousands of an inch with about a 10 inch span like Smith must have? This is what a machine shop with all the tools and the engine on the stand would obviously do. But what about us hobby guys who don’t have this abundance of expensive one-time tools and are doing a cam swap with the engine in the car, which is common. A more “practical” answer is warranted here, such as an estimate of reasonable chain deflection when installed. Come on man.

I have to agree with Gary D. Can we get an alternate answer please.

Why not just measure between the top of the main brg. & the bottom of the cam brg. with a 6″ caliper (that anyone working on engines should have in their tool box) add half of the main & cam journal dia. should get you within .001 or so.

This won’t help in the car, just lets you know some hack slammed it together, pull it out & see what else is wrong. I learned this the hard way with an engine from a nationally known builder, I won’t name them because they have sold since then.

One more note, not all engines have oversize OD brgs. available. Can’t even get .001- for my 6G62 Mitsi V6.

Hello

Im dealing with a 351w that was line honed/ bored- I had installed a stud girdle-Its almost complete, just installed the cam and went to put the cloyes street roller chain on it an I had over 5/8” slop in the chain- so I purchased a .0010 under chain and sprockets and I still have over a 1/2” slop— tried to find a .0015 under but nobody carrys them anymore—what to do please help?

thought of using a QUIET gear drive but dont want the noise of the gear drive

Please help

what is the distance between the crank and cam on a stock small block chevy

This article says the stock CL is 4.890?

EVERY LS engine listed in the definitive guide says it is 4.914!

Which is correct – .890 or .914?