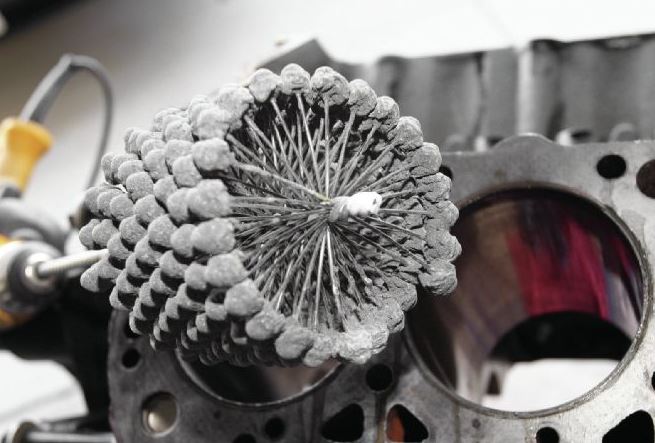

(Image/flexhoneblog.com)

I just bought a used 5.3L iron block engine out of a truck. I’ve decided to put new replacement pistons and rings because I found a set of cheap take-out pistons on eBay. The cylinder wall looks really good as do the bearings so the engine probably doesn’t have a ton of miles on it. Should I run a bottle brush hone through all the cylinders before I put it back together? If so, what oil should I use? Thanks! — B.I.

…

Jeff Smith: This is a great question because it addresses what so many guys are doing now.

Kenny Duttweiler told me several years ago that the honing procedure that GM (and likely all the OEs) use to finish late model engines is exceptional.

In their efforts to produce engines that will run efficiently well past 100,000 miles, block material is now significantly harder than 50 years ago. Also, ring thickness has become thinner. A thinner ring requires less radial (outward) tension, which reduces wear. Combine this effort with the tremendous improvements in fuel control and lubrication and it’s not surprising that these engines are lasting a long time.

I recently tested a used iron 6.0L truck engine on the dyno at Westech Performance. I don’t know the history of this engine so I don’t have any idea how many miles were piled up, but a guess would be something more than 150,000 miles. After the dyno test, which probably helped break loose any carbon built up on the ring lands, I performed a leak-down check on the four corner cylinders and they all came in around 15 percent. That’s pretty amazing since the cylinder walls, rings, and pistons were cleaned but otherwise untouched.

I posed your question to Keith Jones at Total Seal and he said “If the finish on the cylinder wall looks good then a 240-grit hone will certainly help. If there is very little finish left then it should go to a machine shop for a proper honing. This is what I would do either way.”

Keith also mentioned that if you have a Flex-Hone (some people call them bottle brush or ball hones) and you pull up the Brush Research website they list each grit material by a color coding chart. Brush Research offers 12 different grit materials but it appears that the standard 240-grit aluminum oxide material is a good way to go. Summit Racing offers a full line of the Brush Research hones. The aluminum oxide 240 grit hone would be GBD-40024. There are other materials such as boron carbide available in this grit but they are more expensive and probably not necessary.

The Brush Research website offers a bunch of useful tech information. For example, if you are going to use a Flex-Hone, using honing oil is critical. Of course, they recommend their own honing oil available in quart and gallon sizes. Some kind of lubricant is important to prevent the abrasive from loading up and also to ensure the best results.

Most backyard rebuilders will probably use a ½-inch drive electric drill motor and the company suggests using 500 to 800 rpm to start and to run the brush through the cylinder as quickly as possible. This will help establish the desired 45-degree pattern in the cylinder wall.

Once all the cylinders have been honed to your satisfaction, it’s essential that the cylinders be scrupulously cleaned. We’ve found using lacquer thinner works well with either white cotton rags or paper towels. Continue to clean the walls until the paper towels no longer become dirty. It might be useful to try other cleaners to make sure all the grit has been removed. This may require three or four passes through each bore but it is essential to remove all the aluminum oxide grit from the cylinder walls.

Once the bores are meticulously cleaned, regular motor oil will work fine for lubricating the cylinder walls as the pistons are slid into the bores. While most enthusiasts only consider break-in oil for flat tappet camshaft engines, there is considerable evidence that shows that the high content zinc and phosphorous (referred to as ZDDP) additives in break-in oil also helps new hydraulic roller engines as well. You have multiple options for break-in oil and their formulations differ wildly. The highest quality break-in oil that we’ve used is the Driven BR30 for an LS engine in a 5w30 viscosity Other quality break-in oils include COMP Cams and Edelbrock.

Some enthusiasts believe that if some ZDDP is good, then more is better. This is probably a mistake since extreme levels of ZDDP can create problems with ring seal as the zinc and phosphorous build up and are not removed. That’s why a quality break-in oil is important. It’s the balance in additives that we are striving to achieve.

Besides increased ZDDP levels, many enthusiasts assume that engine oils (and especially the diesel oils) with very high levels of detergents are good for break-in purposes. A lower detergent concentration however, is better because detergents strip the zinc and phosphorous off the metal parts they are supposed to be protecting. So the best combination for a break-in oil is higher levels of ZDDP with lower levels of detergents. Current diesel oils now contain lower levels of ZDDP and even higher levels of detergents, so diesel oil is not a good choice for a gasoline performance engine.

I also agree that a professional machine shop/engine builder should be used for cylinder honing to achieve best results. But that’s not always possible and that’s when doing it right with a ball hone becomes becomes essential.

Details such as the suggested drill rpm’s and moving the hone rapidly to get the desired 45 degree cross hatch pattern were covered. But how many passes in and out of the cylinder should be completed for a satisfactory finish ? I’m sure there’s not an exact number but what would be a good count in general ?

What would be?

At least a couple dozen strokes or so, run drill speed rpm’s pretty slowly and move the hone up and down the cylinder fairly rapidly. Stop after a bit too see if you are getting the proper pattern, then adjust your technique if necessary. Service manuals recommend to wash the cylinders with soap & water then rinse with plain water, dry & oil to really get the grit out. Also we sometimes would soft hone after with heavy paper, wrapped around the hone to break off the peaks; Denny R

Thanks Denny. That’s the detailed answer I was looking for.

Dan.

thanks i needed that

\