(Image/Wayne Scraba)

When a camshaft is “degreed” it means the camshaft position in the engine has been synchronized with the crankshaft position. Degreeing the cam is the only positive means to determine if the rise and fall of the pistons correctly matches the opening and closing of the valves.

Several degrees of misalignment can have a profound effect on engine operation (which we’re pretty sure is no secret to most of you).

In a perfect world, you’d need only line up the timing marks on the timing gears (timing chain sprockets or pulleys) and be good to go. But there’s a good chance dimensional stack ups will catch up to you. Things like tolerances in the camshaft, crankshaft, timing chain and sprockets add up.

Which is why checking the relation of the camshaft to the crank (or “degreeing the cam”) is the only option.

Cam-Degreeing Tool List

- Dial indicator with magnetic stand

Learn about choosing a dial indicator here.

- Piston stop

Can be fabricated or purchased.

- Degree wheel

Degree wheels are easy to find.

- Pointer

A pointer can be purchased or easily fabricated. A good old fashioned coat hanger, looped around one of the timing cover bolts and sharpened to a point on the opposite end works perfectly.

In the end, there are a couple of ways to degree a cam.

Now that we’ve discussed the importance of degreeing a camshaft and showcased some of the tools you need to do it, you can read this in-depth article on How to Degree a Camshaft and finish the job.

Here’s a look at a camshaft in the process of being degreed. As you can see, the cam is driven by a Jesel belt drive, which simplifies the process dramatically (but that’s another story). The 14-inch degree wheel is from B&B while the pointer is homemade. (Image/Wayne Scraba)

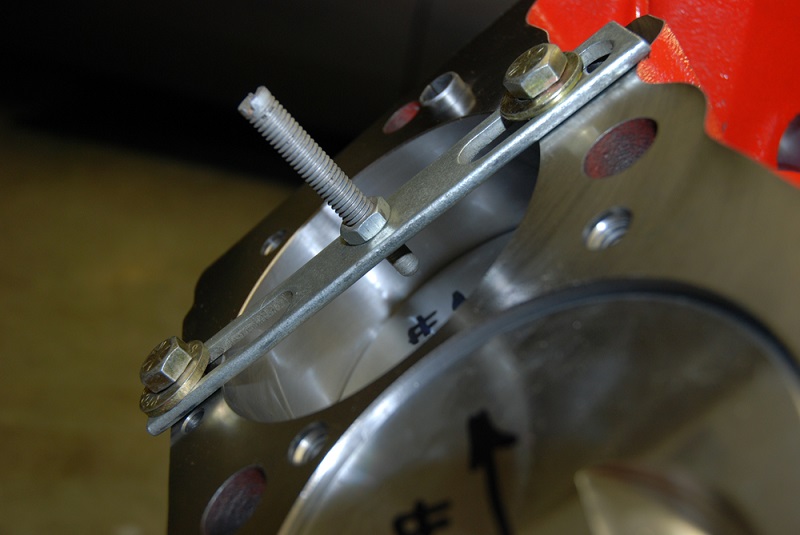

You’ll need some sort of piston stop while degreeing the cam. (Image/Wayne Scraba)

[…] of the events. The intake closing event is the most important to the powerband so you could degree the cam into that. If idle or piston to valve clearance are the most critical, you would set it by intake […]

Love “how to” info!! Keep up the good work!!

Do you see the need to degree a camshaft, when you install a custom ground camshaft. Comp Cams told us that just set the timing gears Mark’s straight up!