Dallas Glenn must be living right.

His day job is crewing for three-time NHRA Pro Stock champion Jason Line at KB Racing. His personal race car is a 1968 Chevy El Camino given to him by his grandma. And he got to build a new big-block bullet for the Elky with assistance from Mr. Line himself.

Glenn grew up in a racing family, starting in quarter-midgets at age five. But the drag racing bug bit hard thanks to his grandfather, Don, who bracket raced a ’55 Chevy wagon. When he turned 17 in 2008, Glenn took the El Camino to the track for the first time. In a sign of things to come, he won his first of nine NHRA Wallys that weekend.

He finished in the Top Four that first season, and won the Sportsman title in the Race of Champions run during the NHRA Division 6 Summit Racing Series Finals. You can read more about Glenn’s racing career in the ‘Dallas Glenn Chasing Win Lights’ story.

Despite a crazy schedule during race season, Glenn drove the El Camino every chance he could. He figures the car has made 1,500 to 2,000 passes down the track from 2008 to 2017, running a best of 11.90 at 112 MPH. Here are the specs for the car and the original 427:

Car

• All-steel body except fiberglass cowl hood

• Factory suspension and brakes

• Turbo 400 transmission and stock 12-bolt rear end with 3.90 gears

• Factory bench seat interior with AutoMeter gauges and MSD ignition box

• Weight: 3,750 lbs. with driver

• 28 x 10.5 rear tires

Engine

• 427 cubic inch big block Chevy, estimated 450 horsepower

• Stock 454 engine block with 4.280” bore

• Factory forged 396 crankshaft, Eagle I-beam rods, SRP forged pistons

• .590” lift solid roller camshaft

• 396 oval port iron heads

• 750 CFM 4150-style carburetor on Edelbrock dual plane intake manifold

But like any good racer, Glenn wanted to turn the wick up. That meant building a new, badder 427. Glenn and Jason Line put their heads together and came up with a list of parts:

• Factory 454 iron block

• Eagle 4340 forged crankshaft and H-beam rods

• SRP forged dome pistons

• Isky solid roller camshaft, 290° duration, .622” lift

• Factory 396 oval port iron heads with bowl cleanup and PAC Racing valve springs

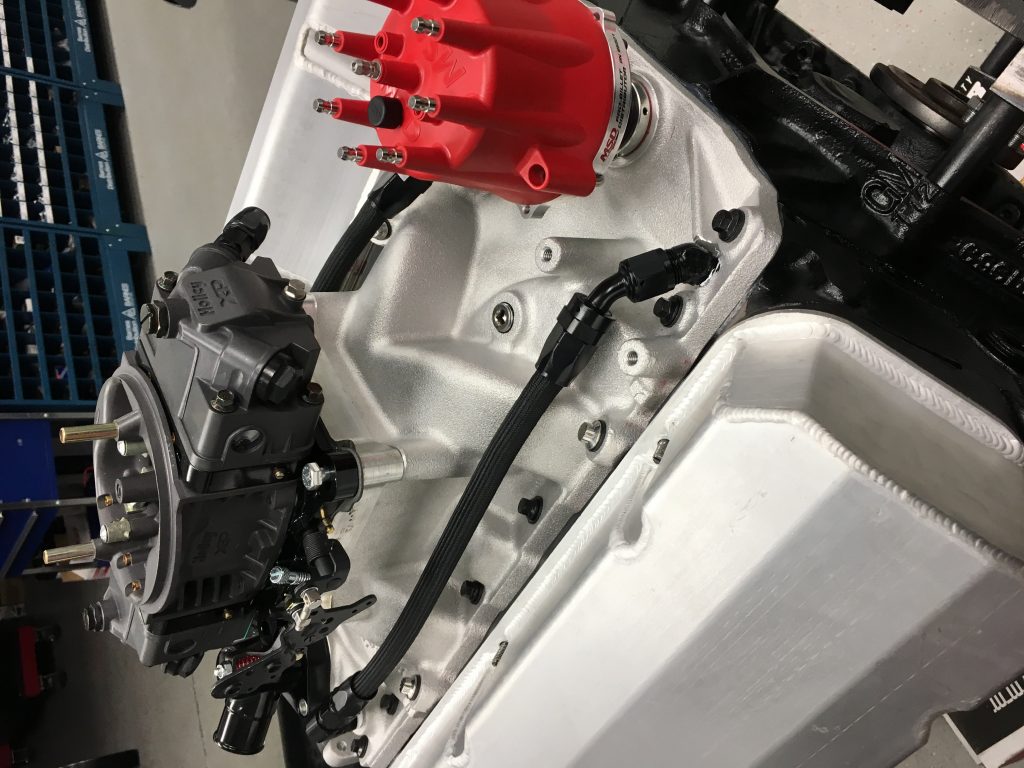

• Holley Ultra XP 850 CFM carburetor on an Edelbrock Performer RPM Air-Gap intake

“My goal was to make more horsepower so I could add at least 150 lbs. to the rear of the car. That will help it hook better and be more consistent,” Glenn explained. “The new engine would be about 50 lbs. lighter, so I could move that weight to the back of the car. I figured around 500 horsepower would be enough to run 11.50s in the quarter-mile, even with the added weight.”

Glenn got his wish, and then some. Tuned on the KB Racing dyno, the 427 made 537 peak horsepower at 6,000 RPM and 517 lbs.-ft. of peak torque at 4,600 RPM. And that is about as much power as Glenn wants, and for a very good reason.

“I don’t want to go any quicker because then I would have to add a roll bar or cage,” Glenn continued. “Doing that would mean making permanent modifications, which I just can’t do to Grandma’s car.”

Want to build a 427 just like Glenn’s? Check out the Dallas Glenn 427 Chevy Parts Combos at Summit Racing.

Dallas Glenn has raced this 1968 El Camino since he turned 17. In that first race season in 2008, he finished in the Top Four in his class, and won the Sportsman title in the Race of Champions during the NHRA Division 6 Summit Racing Series Finals. Glenn’s grandmother gifted the car to him when he graduated high school. We should all be so fortunate

Glenn’s new 427 starts with a 454 iron block with two-bolt main caps. The block is more than capable of handling 500-odd horsepower. Here you see the Clevite main bearings and the ARP main bearing studs, added for some extra insurance.

The reciprocating assembly installed. Down under is an Eagle Specialties forged crankshaft and connecting rods. Made from 4340 steel, the crank has a 396 stroke (3.766 inches) with cross-drilled and chamfered oil holes for improved oiling plus a .125 inch radius on the rod and main journals for increased strength. Also made from 4340 steel, the H-beam rods are 6.385 inches long and set up with floating wristpins and ARP cap screws rated to 180,000 PSI. Add in a 0.30 inch overbore and you get a 427—well, technically a 432.

Flip the block over and you’ll see the SRP forged pistons. The pistons have a small dome to help boost compression to about 10.2:1 with Dallas’ 118cc open-chamber 396 cylinder heads. Features include CNC-machined domes with radiused valve reliefs to provide optimum flame travel, CNC-machined piston ring grooves, and double spiro-locks.

The iron cylinder heads were treated to larger 2.10/1.88 inch intake and exhaust valves, a set of stiffer 1.539 inch dual valve springs rated at 500 lbs./in., and COMP Cams Ultra Pro Magnum rocker arms. The 1.7 ratio roller rockers have investment-cast chromoly steel bodies that are very strong and rigid, which maximizes lift and valvetrain stability at high RPM. The COMP stud girdle further stabilizes the valvetrain by minimizing rocker arm stud movement.

Dallas went with an 850 CFM Holley Aluminum Ultra XP carburetor and an Edelbrock Performer RPM dual plane intake manifold to feed air and fuel to the 427. The race-only Ultra XP features metering blocks with fully adjustable emulsion bleeds, power valve channel restrictors, and idle feed restrictors. An integrated bypass valve eliminates the need for holes in the throttle plates and help maintain the correct plate to transfer slot relationship and good idle control when using radical camshaft profiles.

Dallas getting the 427 ready for a test session in one of KB Racing’s dyno cells. Check out the slick in-floor engine stand rail system for moving the engine in and out of the dyno cell. With tuning help from Jason Line, the big block made 537 peak horsepower at 6,000 RPM and 517 lbs.-ft. of peak torque at 4,600 RPM.

Comments