Some old habits die hard.

That applies to many things, but certainly to hot rods and street/strip cars. Take the basic clutch for example: In the 1970s, the clutch package to have was a Borg & Beck or Borg & Beck/Long combination pressure plate, a sprung hub disc, and some sort of steel flywheel.

The reason this combination was good is because the old diaphragm pressure plates found behind most GM products (and a few other cars) offered pretty good pedal feel, but they often had one ugly tendency: they could stick to the floor at wide open throttle.

That wasn’t fun.

Those OEM cast-iron flywheels weren’t exactly a bonus either. The aftermarket combination of choice worked well, but there was a pretty big issue with it: in order to make the whole thing function, there had to be a lot (and we mean a LOT) of pressure-plate pressure.

The end result was a car that was a royal pain to drive and one that would bend the clutch linkage with ease. Some cars even suffered from bent firewalls from the excess poundage. In other cases, the clutch was so aggressive it would rattle the springs right out of the disk. Or worse.

Fortunately, time and technology have marched ahead. Sure, multiple-disc clutches are hot news (and there are some really good setups out there), but what racing really brought to the table over the decades is a whole new world of disc friction materials. The friction materials are now so good that you don’t need a pressure plate with 3,000+ pounds of static pressure to make the disc work. Instead, the disc does much more of the job, and because of that, the static can be reduced dramatically—so much so that the once-maligned diaphragm pressure plate is now much more common.

Let’s stop here for a moment and ponder the variables involved in picking a clutch: The folks from Hays point out that load plays a huge role in determining the clutch you need for your car. Direct from Hays, here are the factors to consider:

Vehicle Weight

“Vehicle weight plays a big role when choosing a clutch. Many older cars are very heavy and have engines that produce high torque numbers at lower engine speeds. This creates a high load situation on the clutch that can result in a slipping/overheating clutch if the wrong clutch is selected. The heavier the vehicle, the higher the load on the clutch and the more clamp pressure needed to move the vehicle.”

Horsepower and Torque

“Knowing how much horsepower and torque will give you a good idea of what clutch is needed for you application. The higher the operating RPM range of an engine, the more centrifugal clamp pressure is applied by the pressure plate. High-torque, low-rpm applications will require higher clamp pressures while lower torque, higher rpm applications will require lighter clamp pressures.”

Rear End Gearing

“High rear end gearing puts heavier load on the clutch system as well. If you have ever tried to let out the clutch from a stop in second gear, you likely experienced difficulty getting the vehicle moving without ‘bogging’ the engine. This same effect occurs when too high of rear end gearing is used. This situation also requires the clutch to be slipped more on take off to make a smooth transition, resulting in accelerated wear to the clutch.”

Tire Selection

“Tires with more traction, such as drag radials or slicks, allow the vehicle to hook up harder and are less likely to spin than street tires. When a tire spins, the load on the driveline is decreased, but when the tire hooks up, the load on the clutch is increased substantially requiring more clamp pressure.”

Intended Use

“The intended use of the vehicle when choosing a clutch is the most important consideration. A clutch designed for better performance in your street car will not work overall in terms of longevity if you drive real aggressive. Clutch kits are available for street performance to all out racing and everything in-between so be sure you choose the right clutch for your driving style.”

…

If you have a big power street car or a street/strip car, the latest 650 clutch from Hays is right up your alley. It’s engineered to handle as much as 650 hp in a high performance street application. Equally important, the Hays 650 clutch is perfectly happy if you decide to pound gears on the drag strip.

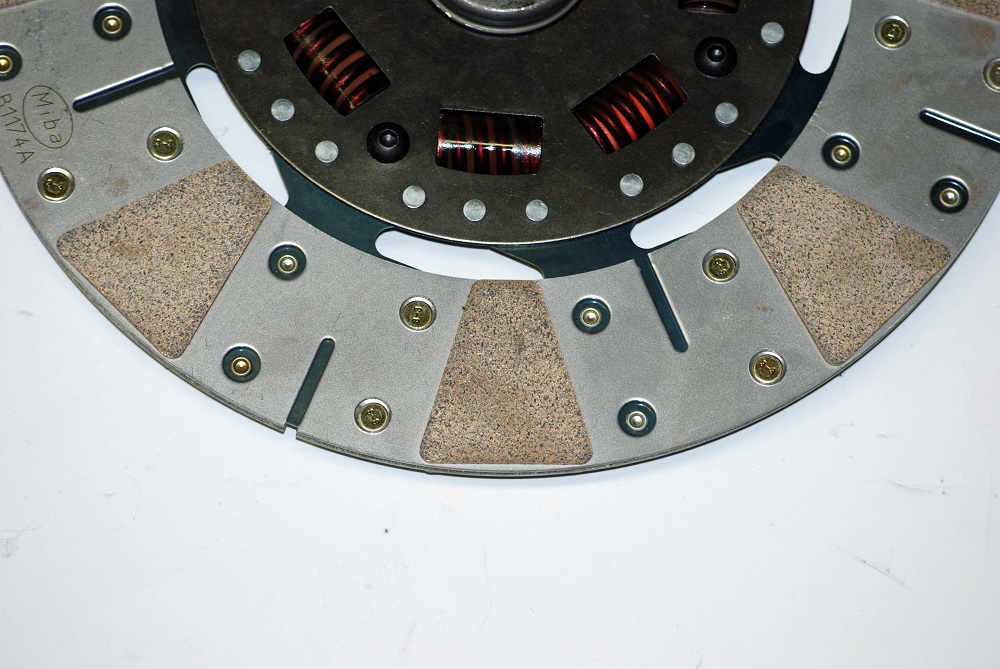

First, consider the Hays disc incorporated in the 650 series clutch: a key ingredient is the Miba PCC friction material (this is essentially a copper-based sintered metallic). Organic clutch discs are typically easy to shift. Conventional sintered metallic clutch discs are not as easy to shift. Organic discs are typically easy on mating surfaces. Conventional sintered metallic materials are resistant to wear, but they take their toll on mating surfaces. Miba PCC friction materials have all of the positive benefits, but none of the disadvantages.

According to the folks who make it, these are the key properties of a Miba PCC friction material:

- High friction coefficient stability

- High resistance to wear

- Damping of friction vibrations

- Increased power density

In operation, the Miba PPC sintered material Hays uses does a great job when it comes to dissipating heat and simultaneously, providing a degree of slippage on the launch. It also provides for a smooth engagement, which means you won’t be fighting clutch chatter on the street.

There’s more too: the Hays disc is also designed with an eight-spring hub. Each of those springs is encapsulated. According to Hays, the encapsulated spring can handle three times the shock load versus a standard coil spring. In addition, the disc is laid out with a Marcel. This is the wavy sheet-metal wafer sandwiched between the friction materials.

The job of the Marcel is to allow the clutch engagement to be smooth and gradual. Otherwise, it can grab with too much force and you can end up with chatter. Vehicle application and the friction materials determine the thickness of the Marcel. More cushioning in the friction material means you can decrease the Marcel thickness and vise-versa.

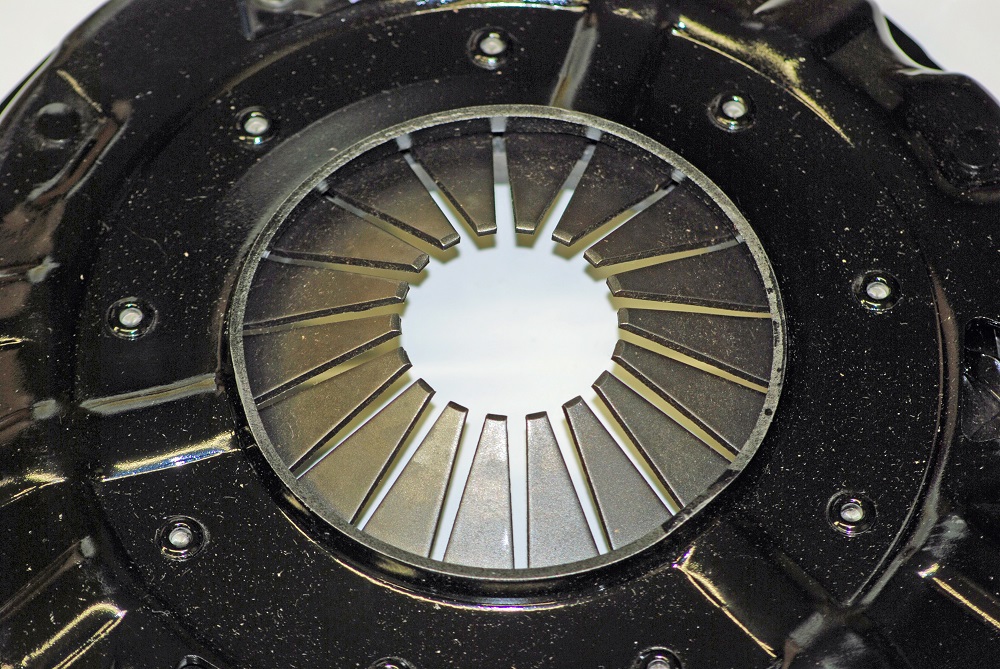

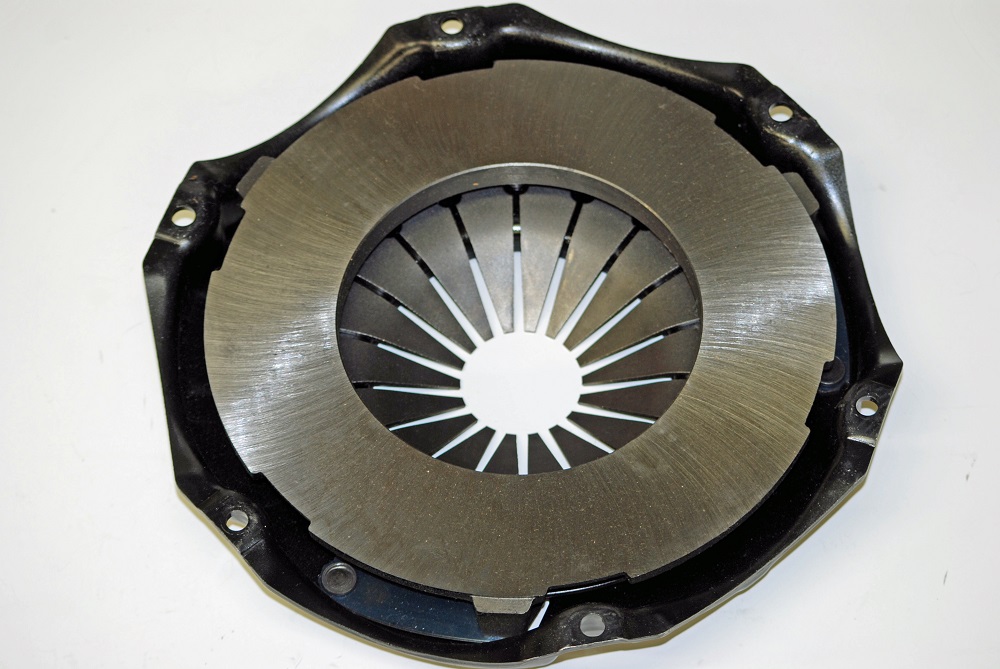

As far as the pressure plate is concerned, many of the Hays 650 applications rely upon a traditional diaphragm design. While it looks stock, it does offer approximately 30-percent more clamping power than OEM designs, but the pedal pressure is still light enough that you really don’t need to worry about going to the gym to work out on leg presses. Anyone can drive a car equipped with the Hays 650 diaphragm.

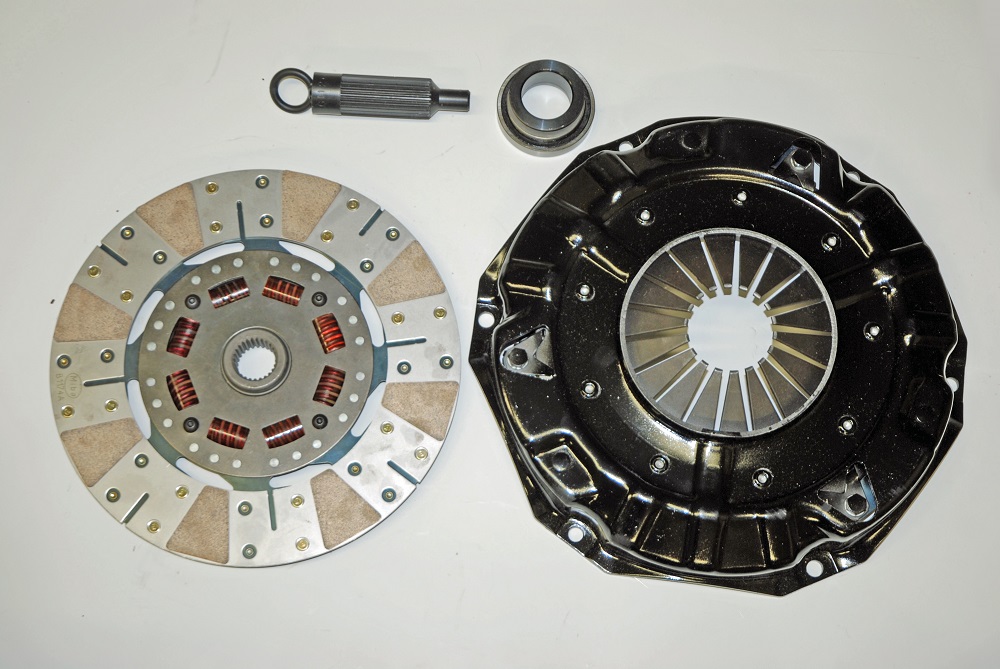

Hays packages the 650 clutch in kit format. What you get when you purchase one is the disc, pressure plate; throw-out bearing, and a clutch alignment tool. If your pilot bushing needs replaced, you’ll have to supply that, and as far as the flywheel is concerned, that should be selected for the application.

A high-strung, high-rpm small block is going to need more flywheel in order to get moving than a low-rpm, long-stroke big block. For example, the flywheel setup shown in the accompanying photos is a relatively light 25-pound billet steel job from Hays. It’s going into a 540 big block powered car that will tip the scales at less than 3,500 pounds. Bottom line here is, the car doesn’t need a lot of help from the flywheel.

“When choosing a flywheel take note that a heavy flywheel stores more energy as it spins than a light flywheel. If you have a heavy car combination that requires more power (or inertia) to make it launch without bogging the engine, you will want a heavier flywheel,” according to Hays. “Remember that a heavier flywheel will be slower to accelerate through the gears where a lighter flywheel creates less inertia at launch but will accelerate faster through the gears.”

Another cool part about the Hays 650 clutch system is the fact they offer a huge range of fitment. There are 44 different GM, Ford, and Mopar combinations available. You can check out Hays 650 and other other Hays clutch kits here.

In the clutches? In this case, it’s a pretty good place to be. For a closer look, check out the accompanying photos:

Comments