I’ve seen in a 4.8L LS engine story where you used a COMP short duration hydraulic roller cam and the engine made really good power. That cam, if I recall was around 215 degrees of duration at 0.050. I can buy a used LS7 cam that’s almost the same duration and would be a lot cheaper. Would this work in the 5.3L LS engine I’ve swapped in my ’74 Camaro? My engine has an Edelbrock Performer RPM dual plane intake and the MSD ignition conversion but still has the stock cam and I’m looking for more power. — K.D.

…

Jeff Smith: General Motors built more 5.3L LS truck engines than any other single late model Gen III/IV engine. At 326 cubic inches, they are a great little engine and an inexpensive way to swap an LS into an earlier car.

This is a great question since the LS7 cam specs appear to be somewhat similar to the COMP cam that we’ve used several times. While duration does play a part in this equation, it’s actually the lobe separation angle (LSA) that is the main reason the aftermarket camshaft works so well. Here’s how this all plays out.

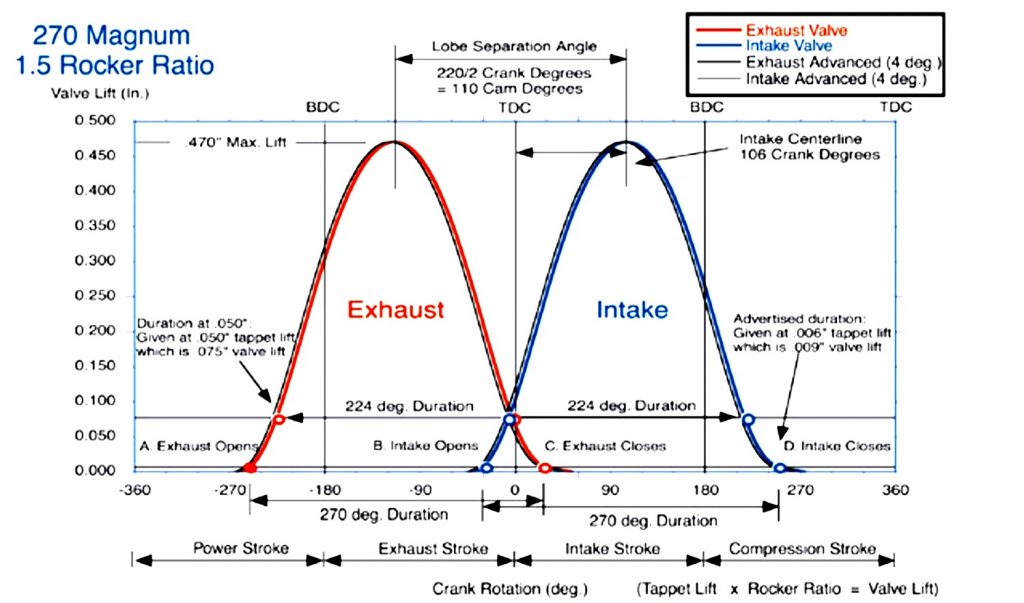

We’ve included a COMP Cams graph that shows two large bell curves that represent the lift and duration of the exhaust lobe on the left and the intake lobe on the right. The peak of each curve represents maximum valve lift while the total width of each curve is the duration. In the middle between these two curves you can see a small triangle-shaped area. This is formed by the exhaust valve closing point as it overlaps with the opening point of the intake valve. This little triangle creates what is called valve overlap, expressed as the number of degrees when both the exhaust and intake valves are open at the same time.

Overlap is affected by two situations. The first is duration. If we increase the duration of the exhaust lobe in the graph, this creates a later closing exhaust valve and will increase overlap. Or, if we increase intake duration, this will do the same thing. Of course, the opposite is also true where reducing duration decreases the overlap.

The next big variable is the position of the intake and/or exhaust lobe centerlines. The centerline is most often placed at the peak lift position. Looking at the graph again, moving the exhaust lobe centerline to the right (retarding its position), will increase overlap. Moving the intake centerline to the left will advance the centerline position and also increase overlap.

All of these factors directly affect lobe separation and overlap. The factory LS7 cam has fairly similar duration numbers to the COMP Cams camshaft. The COMP cam offers a little more duration and lift but the real reason it works better is — as you’ve probably guessed — is because of the LSA.

Factory camshafts must always idle as smooth as possible. So in the case of both the LS7 and the LS9 camshafts, note that the LSA is in excess of 120 degrees. As the LSA is spread apart — producing a larger LSA number — the overlap is reduced and the idle becomes increasingly smooth. Conversely, as the LSA is narrowed — to perhaps 110 or even tighter to 108 degrees — the idle quality will begin to become choppy, producing that unstable burble that everybody likes.

But beyond idle quality, overlap also has a profound impact of torque and horsepower. As an example, our good friend Richard Holdener just posted some data on a cam swap he performed on a 5.3L truck engine that is probably very similar to your engine. He baselined the 5.3L engine with the stock 5.3L cam and induction and a set of headers and then added the LS9 cam, which is very similar to the LS7. The good news is that he picked up an amazing 60 horsepower with this swap. His engine made a little over 400 horsepower with just the cam swap. The horsepower gain can be directly attributed to increasing the duration from 191 to 211 degrees — a 20-degree jump. Plus the valve lift improved by almost exactly 0.100-inch.

Here’s the down side to that swap. In order to maintain a decent idle, you can see that the LS7 and LS9 cams with longer duration have to widen their LSA from the truck’s 115.5 to as much as 122 degrees. One issue with overlap is that decreasing the amount of time the two valves are open at the same time (widening the angle from 115 to 120 degrees in this case) will dramatically reduce low and midrange torque. So in Holdener’s dyno test while the engine gained 60 hp, the engine also lost more than 30 ft.-lbs. of torque below 3,500 rpm.

For a street-driven vehicle with an engine that is already short on displacement, that loss of torque at those lower engine speeds is not a good thing. When the engine only makes around 350 ft.-lbs. of torque at 3500 rpm, a loss of 30 ft.-lbs. is nearly 10 percent and that makes the engine feel soggy and unresponsive. A friend tried this LS7 swap in his 5.3L pickup and changed the cam back out in a matter of weeks because it ran so poorly down low.

The reason that the LS7 engine can get away with this is that is has a much larger displacement of almost exactly 100 cubic inches and that this engine is intended to make good horsepower while willing to sacrifice dome torque down low. But it still drives fine because of the greater displacement.

Now, if we increase the duration, improve the lift and then tighten the LSA from 120 degrees to 110 degrees, this adds torque down low and will improve peak torque over the stock cam while also adding horsepower at the higher engine speeds. This is why that COMP camshaft works so well. The specs are listed in that same cam spec box at the bottom — the COMP part number is 54-456-11.

| Camshaft | Duration @ 0.050 | Valve Lift (inches) | LSA (degrees) |

|---|---|---|---|

| LM7 Intake | 191 | 0.457 | 115.5 |

| LM7 Exhaust | 190 | 0.466 | |

| LS7 Intake | 211 | 0.558 | 121 |

| LS7 Exhaust | 230 | 0.558 | |

| LS9 Intake | 211 | 0.562 | 122.5 |

| LS9 Exhaust | 230 | 0.562 | |

| COMP Cams – Intake | 219 | 0.607 | 112 |

| COMP Cams – Exhaust | 227 | 0.614 | |

| Summit Pro LS – Intake | 218 | 0.523 | 112 |

| Summit Pro LS – Exhaust | 227 | 0.524 |

If you’re looking for other alternatives to the COMP cam, Summit has recently introduced a line of Summit Pro LS performance hydraulic roller camshafts. The one we chose is very close to COMP’s LSR Cathedral Port cam with some minor changes. The duration at 0.050 is very close to the Summit cam with almost the same LSA but delivers a little less valve lift. This way, you can use stock type LS6 valvesprings that are quite a bit less expensive than the springs that COMP recommends using. The Summit cam is also about $80 less expensive than the COMP version and you can reuse the stock retainers and locks. This might be a less expensive way to go that will deliver most of the power gain of the COMP cam. Choosing a camshaft can be very difficult unless you have all the facts, so it was a good idea to ask first before just jumping right in.

Hey Jeff,

I have a question to a thread you wrote from around a year ago regarding 6l80e transmissions. I have a 2017 5.3 with a 4×4 6l80e. I would like to use this trans and motor combo with a corvette type irs differential. From what I understand the 2wd output shaft is longer than that of the 4×4 version. My question is this…Do I just need to switch to a 2wd output shaft to make this work? Or is there a more simple way? Which differential should I be looking forto best fit this? This project is for a mid engine sand rail conversion so I am attempting to keep overall motor,trans and diff length down. Thank you for your time!

I have 2005 Chevy avalanche with 5.3l vin code z what vin code and years that will fit my truck

How’s it hanging Jeff

I’m building a 5.3l vortec for 03 tahoe 4/4

My question is what cam will give me good tourqe and some hp

Hey Jeff,

I have a stock 05 chevy 5.3 with a L33 engine and I want to do a cam and lifter swap. Was just wondering if I needed to change anything else in order for the Pro LS cam or comp cam to work?

Regards,

Craig

Tengo una chevy silverado 2008 con dod sistema

Pero le instale un camshaft. Vvt dod

Mi prefunta es y ahora presenta misfire en dos cilindros de motor

A que. Sedebe ese problema y como se podria solucionar

hello jeff i have a 2003 5.3 lm7 i also have a set of 799 heads my plan was to mill the heads 20 thousand and install a new aftermarket cam kit.i can tell you this engine is going in a 1953 5 window chevy truck with auto and 342 posi the wife and i are going to drive this alot on small trips we would like to have a truck that has some thump at idle and performance low to midrange and still be able to cruise around be able to do a healthy burnout and get better than 6 miles per gallon. what recommendations do you think

I read your article on cams but still lost . Can I put a choppy cam in 5.3 vortec

I have a 5.3 l long block ready that 450 horsepower that I bought from summit racing it has a 550 lift cam with a 222 231 split duration I am switching it out to a summit Cam s u m 8707 it has a 600 lift 238 226 split duration about how much horsepower gains can I make swapping these two cams looking to get about 500 to 525 horsepower out of this 5.3

Swapping an 1999 LM7 5.3 into my 1987 Fire Bird. rebuilding motor with flat top pistons and keeping the factory heads, also am boring cylinders to clean them up (Probably 20 Over). Planning on 373 rear end, stock truck intake and I am going to run Summit 8720 high lift truck cam. Just trying to have a fun street car with a strong mid range and occasional high RPM to about 6300. Do you think this cam is to small and what torque converter? My transmission did not come with one so I have to buy one anyway. 4l60e getting rebuilt.

i have a 2017 chevy 1500 5,3 with the l84 engine, the camshaft has been replaced and now times 180 out no matter how may times i reset base engine timing , compression is when crankshaft mark is 12 oclock and camshaft mark is at 12 oclock instead of 12 and 6 is it possible that the wrong cam has been installed.

I have a 5.3 where my 3rd cam bearing walked out. So trying get the engine done but my cam bearing tool wont go through cam bore hole. What would be the cause.