So what would you do if a company called you and offered up a 5.3L test motor? Now what if these same guys gave you their blessing to throw the kitchen sink at it? Now, what if said motor was of the boost-ready variety, and was just begging for nitrous, a blower. or pair of turbos?

Now that we have everyone excited, you should know, this test isn’t about boost…but fear not, those tests will come later!

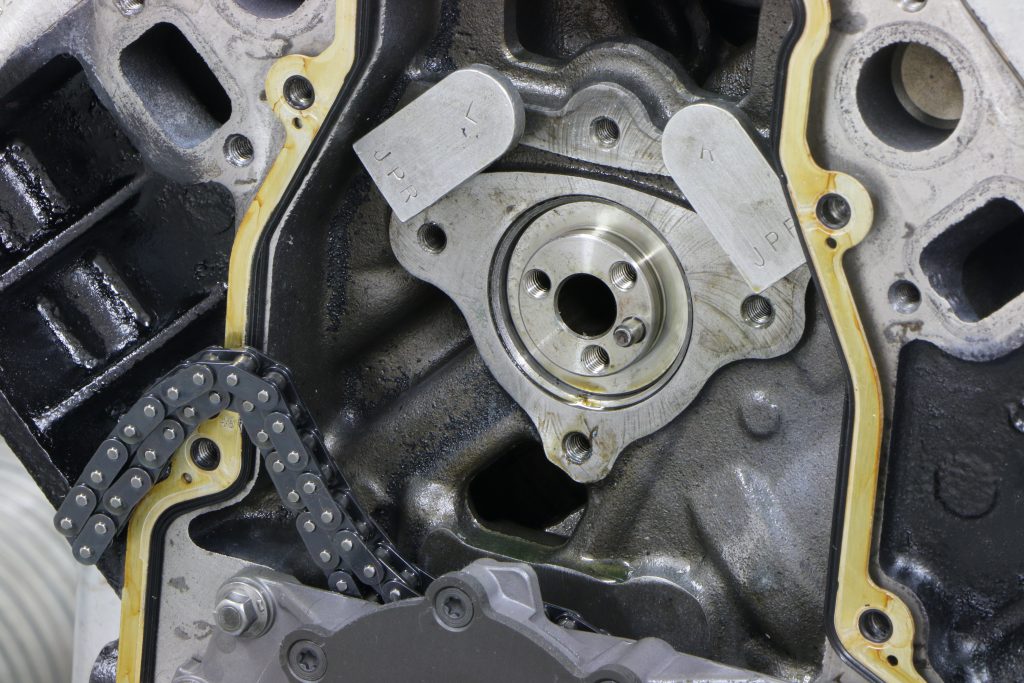

For now, we took the guys from Strictly Performance up on their offer by subjecting their 5.3L to some serious dyno time, starting with the most popular LS modification out there: a cam swap! A serious step up from our usual, crusty, junkyard special, this 5.3L was not only clean and shiny, it had more than a few desirable features. Included on that list was stock block and crank, along with the more desirable, Gen. IV rods and hard-anodized, flat-top (cast) pistons. Topping that short block off was a set of Katech-ported 706 heads, secured with ARP head studs and LS9 head gaskets.

In short, the 5.3L was what you might do to your own motor in preparation for a turbo or blower, but it was also the perfect little (near-stock) 5.3L combination for our cam test!

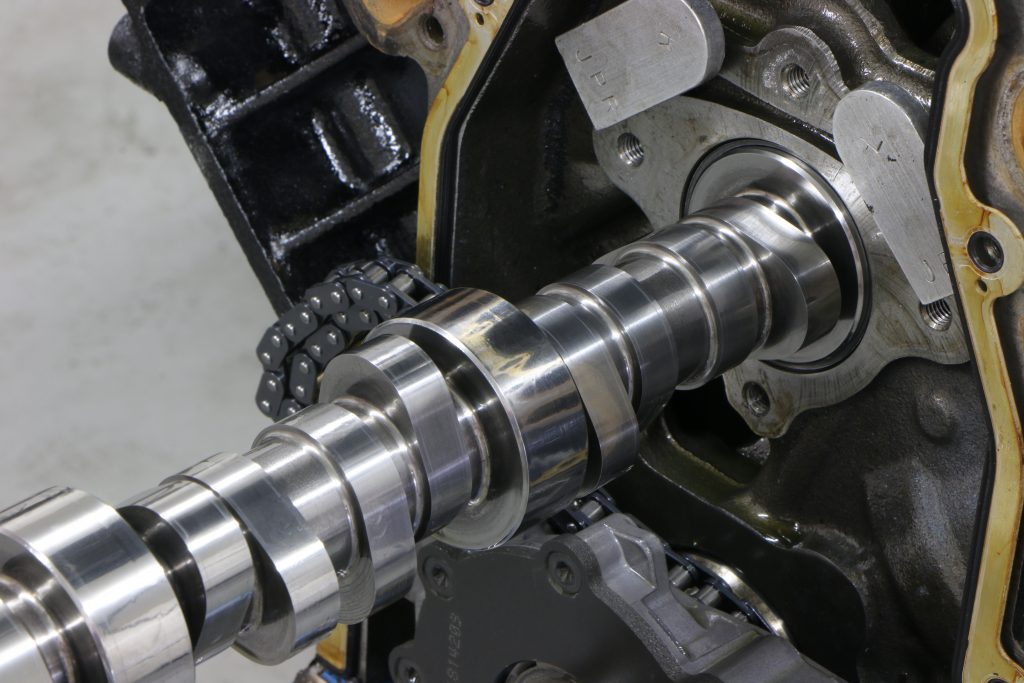

Before we could successfully start swapping cams, we had to make a few changes to our test motor. First on the to-do list was to replace the turbo cam originally supplied with the 5.3L. Out came that cam and in went a factory LS9 cam. Sure, we could have started with an even milder (by some 50-60 hp) LM7 cam, but every cam looks like a hero compared to the mildest factory offering. We chose the LS9 because it is the most powerful of the LS-based factory cams, though the nearly identical LS7 (predictably) offered identical power numbers when compared to the LS9 on a 5.3L. By choosing the LS9, we set the bar a little higher for the new Summit Racing Pro LS Stage 4 cam.

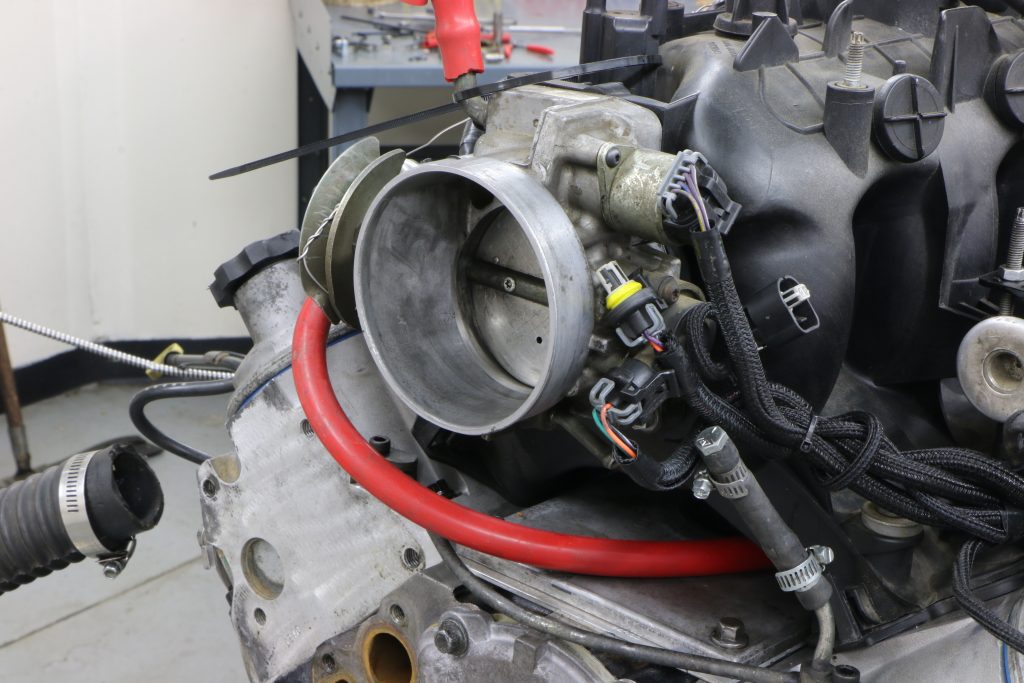

In addition to the installation of the LS9 cam, we had to complete the 5.3L with both induction and fuel systems. To feed the 5.3L, we selected an early stock truck intake and manual throttle body. The fuel needs were supplied by a set of 80-pound Accel injectors fed by an Aeromotive fuel pump. The 80-pounders would later be put to use with a TorqStorm supercharger, but they worked equally well on our naturally aspirated cam swap. To dial in the air/fuel and timing, we selected a Holley HP management system. Both cams were run with identical A/F and timing values, though we tried others values in our quest for maximum power from each.

The mechanics of the back-to-back cam test were pretty straight forward. All we had to do was dial in the tune on the LS9 cam, then perform the same procedure on the new Summit cam. Speaking of the Stage 4 cam, the Summit grind was a healthy customer.

Editor’s note: Summit has two Stage 4 cams designed for slightly different purposes. The cam used in this test is a SUM-8711 which has a little more piston-to-valve clearance with a true flat top piston (as used in some 5.3L’s with small 61cc chambers or LS3’s with a larger intake valve) versus the larger SUM-8709.

The Stage 4 offered a .625/.605 lift split, a 234/247-degree duration split and 113+3.5 LSA. This compares to the .558/.552 lift split, a 211/230-degree duration split and (wide) 122.5 degree LSA offered by the LS9.

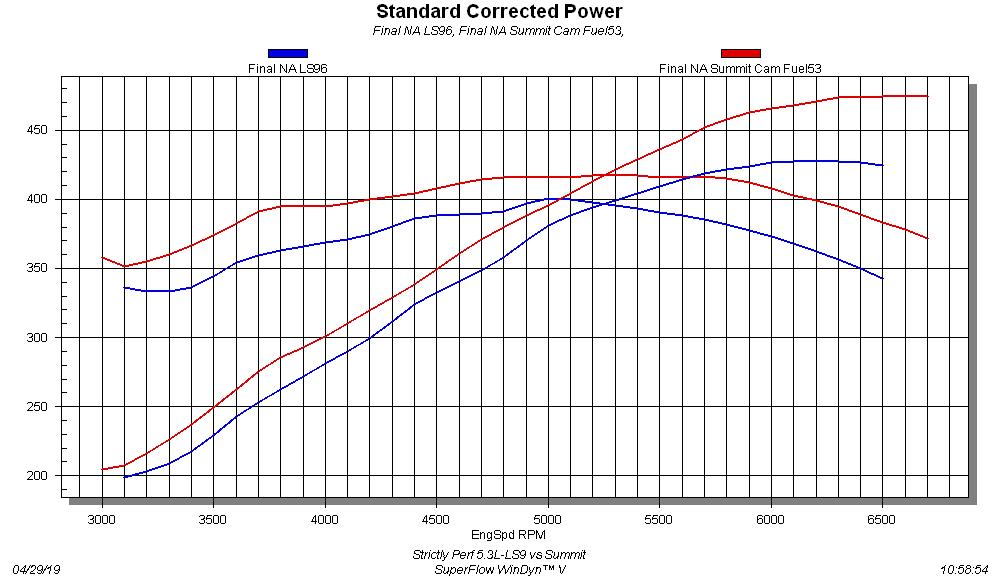

Run first with the LS9, the 5.3L produced 428 hp at 6,200 rpm and 400 (399.9) ft.-lbs. of torque at 5,000 rpm. We know the LS9 was originally designed for a boosted application (6.2 liters no less), but it worked well on our little, naturally aspirated 5.3L. After installation of the Stage 4 cam from Summit Racing, the power output of the 5.3L jumped by nearly 50 hp, to a peak of 475 hp (at 6,600 rpm) and 418 lb-ft (at 5,300 rpm). Not only did the Stage 4 cam offer peak-power gains, but it also improved torque through the entire rev range-always a good sign, especially for such a healthy cam. Based on these results, LS owners looking to fortify their motor might do well to take a peak at the Summit catalog!

We’ve harped on it many times in the past, but nothing wakes up an LS motor like the right cam. Rather than our usual junkyard jewel, this cam comparison was run on a mild 5.3L supplied by the gang over at Strictly Performance. The boost-ready LM7 featured a stock crank, hard-anodized, flat-top (cast) pistons and gen-4 rods. Topping the augmented short block was a set of mildly ported 706 heads, an early truck intake and manual throttle body. Run first on the dyno with the LS9 cam, the SP 5.3L produced peak numbers of 428 hp (@ 6,200 rpm) and 400 lb-ft (@ 5,000 rpm). The power numbers changed dramatically after installation of the Stage-4 cam (SUM-8711 variant) from Summit Racing. Equipped with the healthy Stage-4 cam, the SP 5.3L produced 475 hp (@ 6,600 rpm) and 418 lb-ft of torque (@ 5,300 rpm). Were this Stage-4 cam installed in place of a factory LM7 (instead of LS9) cam, the gains would be closer to 100 hp!

Great info!! I am looking into doing a clone of this build. I have a set of ported stock 706 heads with 2″ intake valves installed. I was wondering if the heads used in this test had stock valves or upgraded to 2″. Thank you for your time.

very interesting. I’m quite impressed.

On your lm7 LS build it said it had flat top cast Pistons and you ran a summit racing stage 4 pro Cam was your Pistons fly cut or was they straight flat tops the reason I ask is I have a lq9 with 706 heads that I have had them heads milled 30,000 with factory head gaskets and I really want to run the stage 4 summit racing LS pro Cam but I’m worried about pissing the valve clearance but complete short block is stock

I’m interested in building a motor for a 914 that currently has a ZZ4 crate motor and 4 speed 930 transmission. The ZZ4 torque curve is kinda silly for the because it fries the tires at low speed but then winds to redline and needs a shift in a blink even under light throttle because of the low redline and torquey curve shape.

If one got a junkyard aluminum block LS3 and changed only the pistons, cam, pushrods, trunnions and intake and headers, could one move the power peak to 7000 rpm and shift at 8000 rpm to better match the car light weight and transmission gearing? The idea is as big a cam lift and longer durations to allow the stock heads to flow reasonably up at 7000 RPM, and pistons that allow that kind of lift with cutouts, but push the compression way up to 14 or 15. The big cam will limit cylinder filling down low so max torque for any RPM might not be knock limited or, if it is, so what if a few degrees less than optimal timing is run, it just gives that nice revvvy torque curve. Add something like a simple FI Tech short runner manifold and EFI system and the whole thing is optimized on that high RPM torque curve shape. A cheap high revving sports car motor that only makes crazy horsepower when wound way up on the boil, but is otherwise controllable with short shifting.

Thoughts Richard? Could you build and test something like this?