I bought a set of TFS valve springs (PN 16918-16) for my Summit 8702 cam for an LS engine and I realized these springs are only good up to a 0.610-inch lift cam. My cam is a 0.612-inch lift. Would these still be okay to use? — J.M.

…

Jeff Smith: The short answer to your question is yes because the difference in lift is very small. These TFS beehive springs are made by PAC Racing so we looked up the specs on the springs and compared them to the numbers on your camshaft. Let’s look at what the specs tell us.

The camshaft is a Summit Stage 3 hydraulic roller cam for a Gen III LS engine. The specs are 236/246 degrees at 0.050-inch tappet lift with 0.612-inch lift using the stock LS 1.7:1 rocker ratio. The lobe separation angle on this cam is 110 degrees so it’s got lots of overlap.

Valve springs are designed to be used with a given installed height. This is the distance from the spring seat on the head to the underside of the valve spring retainer. The stock installed height for LS engines is 1.80-inch which is the same spec for these TFS springs. When the spring is compressed to this height, it creates a load that PAC specs at 140 pounds. To put this in perspective, the stock LS1 valve springs are rated at 76 pounds at this same installed height. The PAC spring’s increased seat load helps minimize valve bounce at higher engine speeds with camshafts intended to spin past 6,000 rpm.

All springs also offer a max lift number that is generally 0.050-inch away from coil bind, which is the height of the spring when it is fully compressed and becomes a solid stack. The coil bind number for these springs is 1.140 inches. If we subtract 1.140 from the 1.800-inch installed height, this gives us 0.660-inch of total spring travel. TFS lists the maximum valve lift at 0.610, which produces a clearance of 0.050-inch away from coil bind.

Since your cam produces 0.612-inch of valve lift, theoretically this will reduce the clearance to 0.048-inch. The 0.050-inch clearance is just a recommendation for the minimum clearance to coil bind so even if the actual lift was a true 0.612-inch, this would not produce a problem. We mentioned this as a theoretical lift because there will always be a certain amount of deflection in any valvetrain.

Starting from the lobe on the camshaft, to get maximum valve lift we multiply the peak lobe lift by the rocker ratio. So 0.360-inch lobe lift multiplied by the 1.7:1 rocker ratio equals 0.612-inch of valve lift.

With a total spring load of 328 pounds at 0.600-inch lift, this is multiplied times the rocker ratio — 328 x 1.7 = 557 lbs. of force. This is the amount of load on the pushrods at near-maximum lift.

This much load will generally cause a certain amount of deflection in the valvetrain. It will compress slightly the engine oil in the hydraulic lifter, it may deflect the pushrod, and it also could cause a small amount of movement in the rocker arm. Plus, as the rocker arm travels across the valve tip, this alters the rocker ratio slightly. All of these things can combine to reduce total valve lift by 0.010 to perhaps 0.020-inch. This is especially true with stiffer springs.

Another concern with big-lift camshafts is to also check the retainer-to-seal clearance when assembling the springs. This is the amount of clearance necessary to prevent the bottom of the retainer from smacking the valve guide seal. If this happens, the seal is damaged and that cylinder will begin to use oil. The minimum clearance spec is 0.050-inch.

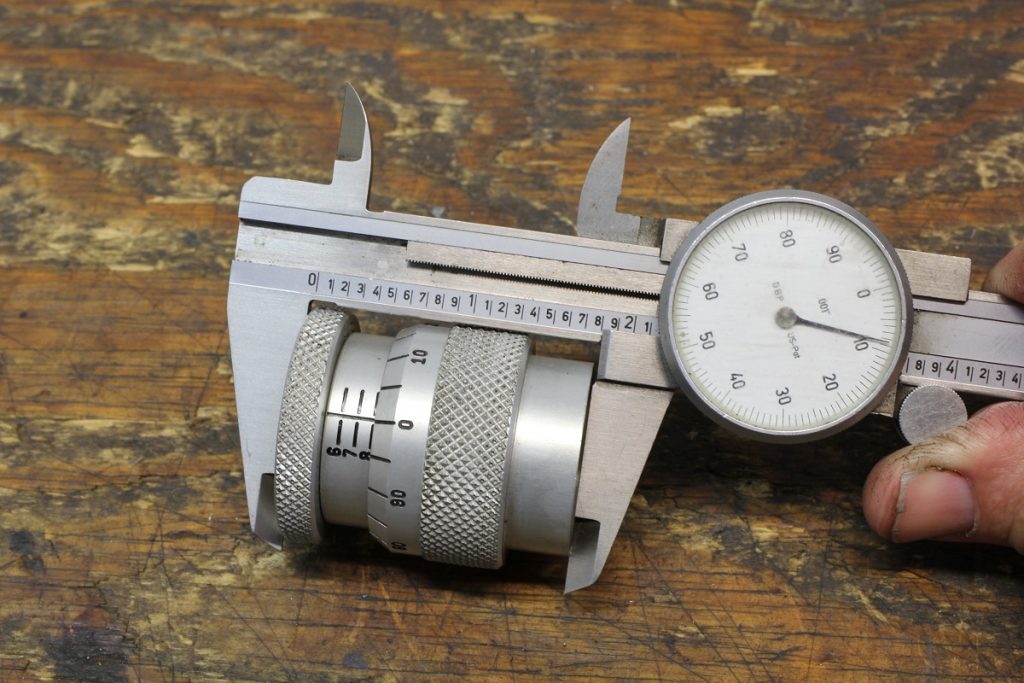

All of these specs are predicated on establishing the correct installed height. This can be easily measured with a tool called a height micrometer.

Several cam companies like COMP Cams, Isky, and Summit Racing sell these tools. The installed height number does not have to be the exact spec, but if you are detail oriented, you can adjust installed height by several methods. If the measured height is taller than the spec, shims can be used to reduce the height. This is the most common situation.

So as you can see, your concern over maximum valve lift is not really an issue but it would be a good idea to make sure the installed height is as close to the 1.800-inch spec as possible. This will get the most out of those springs.

What is best cam for HP/Torque pick up over OEM for an L33/LS Gen III motor staying under 0.600 with stock 1.7 rockers

Thx for the information

Building a 1970 Pontiac YD 400 with 6x-4 heads that’s milled 20, good clean up of runners. Port polish, Ram Air 4 cam, Rhodes lifters, hei high output distributor, 8.5mm wires. Melting double roller. Milling high volume oil pump, told my machine person with the heads I’m looking for 9.5:1 cr. Everything else is setup real nice! Th400 that’s been tuned well and a 12 bolt with 4:56’s. Which I’m soon changing for 3:42’s. Any advice would be greatly appreciated. I’m switching the smaller rocker arms to the 7/16s and installing some 1.6 roller tip good rockers with some max lift .590” valve springs. How’s it sound?

I’m installing S&S 585 valve springs (beehive style). Can you tell me the coil bind height for this spring?

Pontiac 400 rebuild. Mellon cam 406 lift ram air spec…. question is comp valve springs 995 -16 with spring rate at 402 lbs/in too much for this street motor maybe excessive cam lobe wear ??? install height 1.700.

i have a 2004 jeep gc 4.7 ho with 2009 Jeep camshafts, new style rockers, new timing set, 2009 dodge ram intake manifold, new 4 hole injectors, solid lash adjusters and reground the valves with new valve seals. The factory cams specs were H.O. CAMS .472 intake & .429 exhaust. The new cams are 2009 (208?) Cams .509 intake

.472 exhaust. question is what valve springs do I need to upgrade to?