Intake manifold technology has progressed by leaps and bounds over the years. (Or, has it?)

Additionally, there are many more players in the intake manifold business than we saw years ago. For example, there are about 1,900 intake manifolds (both carbureted and fuel-injected) available at Summit Racing.

Decades ago, there were only a handful of manufacturers offering a select few intakes for each engine application.

Bottom line here is, there’s a lot of competition today. And a lot of choice. Some are fresh designs. Some are older. Case-in-point is the Holley Strip Dominator. When they first came out roughly 40 (!) years ago, I was quick to install one on my big block Chevy-powered Monza Pro Gas car (Super Gas wasn’t around yet). The 300-5 worked fabulously and it was head and shoulders above the other available manifolds. That intake is still available today, and remains a very good intake manifold design, particularly if your application needs hood clearance.

Forty years is a long time for a piece of equipment to remain in production (the reason is, it still works exceptionally well). But technology has continued to march on.

Today, one of the go-to manifolds for ‘super’ category racing is the Weiand Track Warrior. It is designed for big cubic inch engines and is particularly well received in the various .90 racing categories.

Holley Strip Dominator vs. Weiand Track Warrior Intake Manifold

How do they compare? While we’re not going to provide flow or performance numbers, we will point out the physical differences (and the similarities) between the two. Check it out:

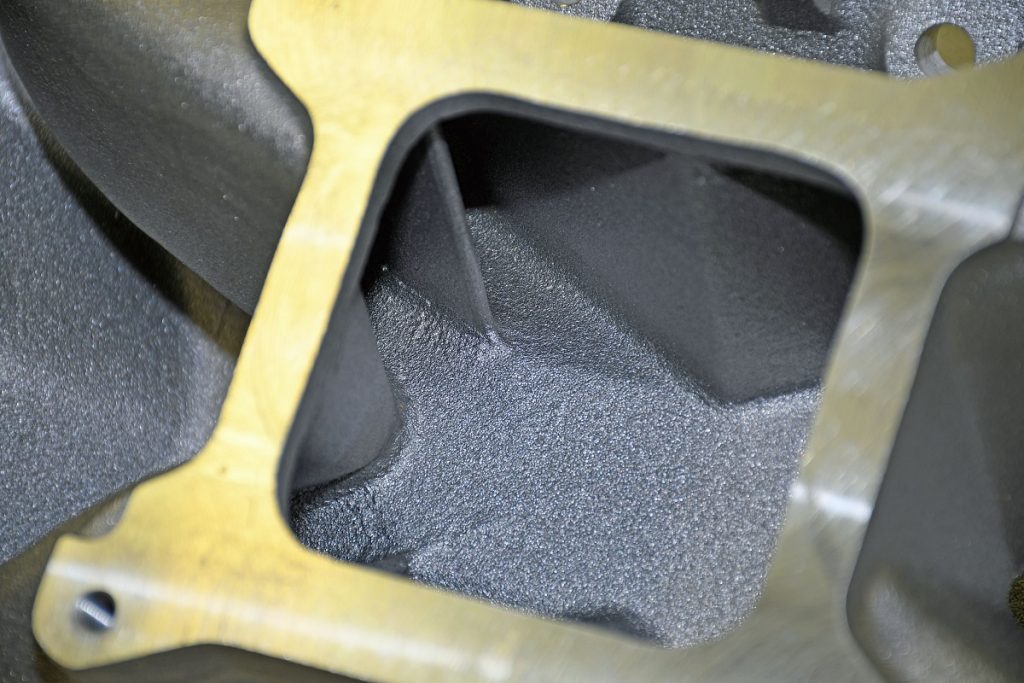

Both intake manifolds are single plane, open plenum designs.

Both are designed for standard 9.800-inch deck height cylinder blocks.

Both are available for oval port and rectangular port BBC applications. The vintage Holley Strip Dominator is engineered to work with a 4150 square bore carburetor. You can specify a Weiand Track Warrior with either a 4150 flange or a Dominator carburetor mounting flange. Furthermore, the Track Warrior can now be ordered for EFI applications.

The Strip Dominator has an advertised power band of between 4500-8500 rpm. Meanwhile, the Track Warrior operates within a 3500-8000 rpm power band.

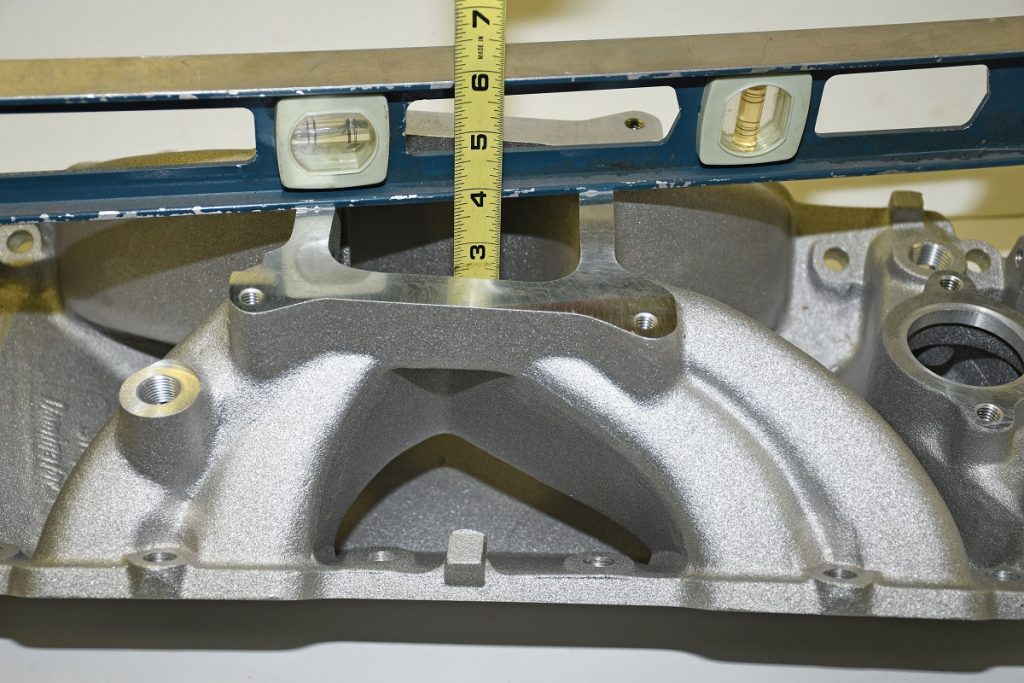

In terms of overall dimensions, the Strip Dominator has an angled carb mounting flange. It measures 6.16-inches above the “China rail” at the rear. It measures 4.77″ at the front of the flange. This angle (similar to several stock production line BBC intakes) is what allows it to fit under the hoods of many cars.

In contrast, the Track Warrior is actually shorter at the rear. It measures 5.96″ above the rail. Up front, the intake is the same 5.96-inch height.

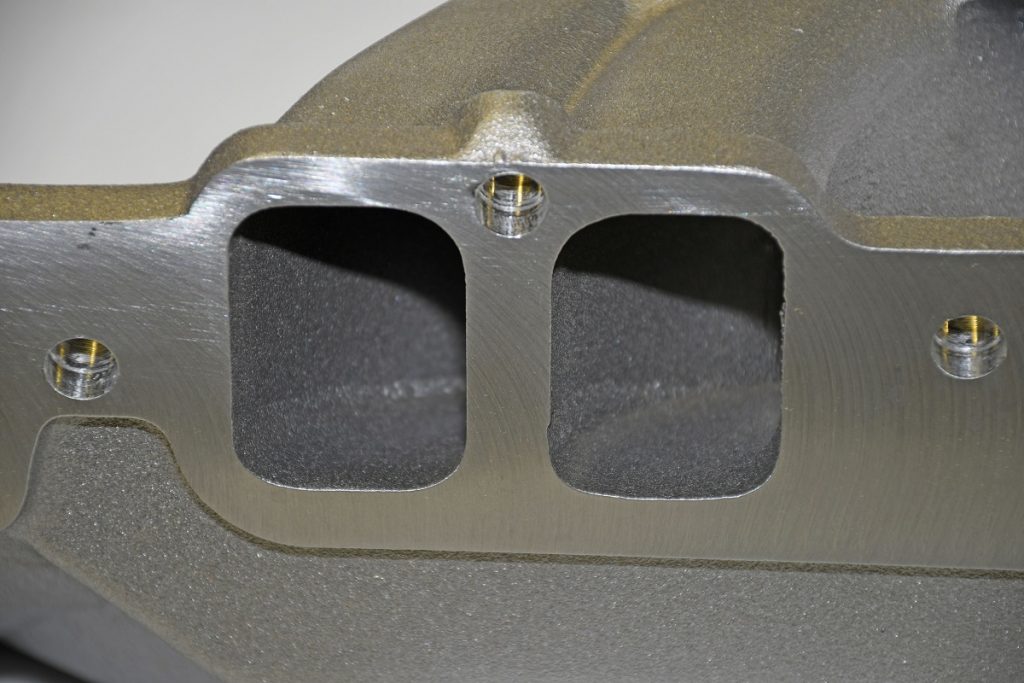

The out-of-the-box port dimensions work out to 2.30″ tall x 1.60″ wide on the Strip Dominator.

The out-of-the-box Track Warrior ports measure 2.28″ in height and 1.48″ wide. As you can see, they’re close, but the Track Warrior is slightly smaller.

Both intakes have plenty of room at the port for port matching (to the cylinder head). In terms of plenum height, the Strip Dominator is approximately 3-7/8″ tall (measured in the center) while the Track Warrior measures approximately 4-7/16″ (in the center). Speaking of plenums, the walls between the respective runners in the Strip Dominator measure from approximately 0.120″ (plenum) to 0.565″ (port) thick. They measure approximately 0.460″ (plenum) to 0.5875″ (port) on the Track Warrior. In both cases, this leaves you with plenty of room for porting.

Externally, the Strip Dominator is designed to work with all OEM intake-to-cylinder head fasteners. This means the pair of bolts on each side of the siamesed runners are in place. Those bolt locations don’t exist on all of the latest Track Warrior intakes. This doesn’t present much of an issue, since many late model aftermarket cylinder heads don’t have these bolt provisions either.

At the rear of the Strip Dominator, you’ll find it still has provisions to mount a canister coil. That doesn’t exist on the Track Warrior. Additionally, the Track Warrior distributor flange is set up so that you can mount the clamp on the left or the right of the assembly. Up front, both intake manifolds have provisions to mount a water temperature sender on either side of the intake, but the Strip Dominator will also accept heater hoses. Both have a water pump bypass port and both come with alternator brackets for pre-1969 alternators (which had a top mount off the intake—later model year examples do not). The Strip Dominator comes with a tapped runner port for a vacuum line.

You’ll find that the casting is a bit cleaner on the Track Warrior. That nicer finish is obviously due to more modern tooling and casting technology.

In the end, pick your intake. Both have similar features and both make great power. But the Strip Dominator actually has more street-oriented features than the Track Warrior.

It’s always informative to see comparisons between proven classic parts and their more modern day equivalents. Wayne Scraba’s credentials as a top Automotive Technical Journalist needs no introductions. His balance of text and great photos in this relatively limited space does an excellent job of getting the point across.

When comparing these two manifolds, the abundant list of measurements really help. For example, the Track Warrior’s taller overall plenum height would suggest that it has more plenum volume than the Strip Dominator. But the Warrior’s port dividing walls are much thicker and extend further toward the center of the plenum than the considerably thinner and shorter port walls of the Dominator.

The result should be a measurable reduction in the total plenum volume of the Track Warrior. That’s not necessarily a good or bad thing but considering how some builders are real sticklers for minute details and how critical the plenum volume might be for the specific goals of the builder, it’s the sum of little details that consistently results in a win light.

I have an old school example of intake manifold technology that despite being out of production for decades and considered obsolete, it still performs quite well when combined with high compression and modern solid roller cam profiles. It’s an Edelbrock “Scorpion” intake designed for Ford 351 Cleveland, 4-V heads. It’s a single plane design that resembles the original Edelbrock Torker 351C, 4-V intake but has a slightly taller plenum design and a higher peak RPM range.

It’s rare to see one for sale and when most Ford builders find out that I have one, they want to know if it’s for sale. It’s not but there must be a pretty good reason for all of the inquiries.

And the beat goes on…..

Regardless who wrote this article without any real world numbers like port volume, port flow, port velocity and how these two intakes performed on the exact same engine THAT WAS DESIGNED TO RUN IN THAT RPM RANGE this article is basically useless unless all your interested in are the under hood dimensions. An engine needs a certain amount of air and as long as the intakes characteristics can provide that air flow and atomize the fuel properly it will make good power. Anyway good article if you didn’t really want an answer.

The Holley SD intake manifold looks like it’s for a Big Block Chevy as it shows 8 hold down bolt holes on each side of the intake manifold. But the Weiand TW has only 6 hold down bolt holes on each side of the manifold (“Looks like it’s a Small Block Chevy intake manifold”)

So how can you compare the measurements of both these intake manifold against each other if they are not both for a Big Block Chevy’s ??

Or did Weiand TW eliminate the extra hold down bolt holes that are present on the Holley SD intake manifold ??

Inquiring minds want to know what are the two intake manifolds for ??

Both manifolds are for a BBC, the Track Warrior simply doesn’t have the bolt holes above the port runners. A lot of aftermarket heads don’t have these bolt holes, so the intake manufacturer simply skips this step. Not a big deal.

I would like to see how they worked, you can give all this information but put each on the same car and then explain the results.

I’m about to sort of a mechanic I’ve been doing this for about 40 years I have a a customer with a k5 blazer with a belt 350 small block I’m assuming it’s got to have at least a 630 or 640 cam in it they’re using a torque or two intake probably made in the seventies they put a Edelbrock performer carburetor on it and I have tried to tune this thing it has a severe flat spot in it carburetor’s new distributors New timing is set up 32° full advance still at idle trying to get this thing to roll down the road you have to Pat the gas to put some fuel in it to get it to go my experience tells me that the intake is way too much for that heavy vehicle to drive in traffic I believe it’s made for idle and wide open throttle drag racing that’s it I wonder if my assumption is right I believe it is they’re going to have to change the camshaft to calm it down and put a dual plane intake on it to give the fuel some direction instead of dumping down the road that intake once you get it up and rolling it runs fine but off of idle under normal acceleration it runs really bad but just at all the valves did a compression test everything mechanically is appears to be good I’m looking at telling the customer to replace the intake camshaft I see where somebody put screw in rock arm adjustments studs on the head so it did not put guy plates or self centering rocker arms which will be a problem in the near future please give me your opinion

Fair assessment,use a Edelbrock Performer Air Gap(idle to 5500rpm) or Edelbrock Performer RPM Air Gap(1500-6500).

How about the Edelbrock S-P2P and the Offenhauser Dual-Port next? 😉

What happen to the edelbrock tarantula single plane manifold for the small block chevy..I had a 302, 69 z28 that I ran that manifold..building another one can’t find that manifold