Q: What is the difference between a flat tappet and a roller camshaft?

…

A: Camshafts are classified by the type of lifter they use.

The lobes on the cam are machined differently based on the intended lifter. Lifters are sometimes called a “follower” or “tappet.” They contact the cam lobe with either a flat surface or a wheel.

Flat Tappet vs. Roller Camshafts

Flat Tappet Lifters

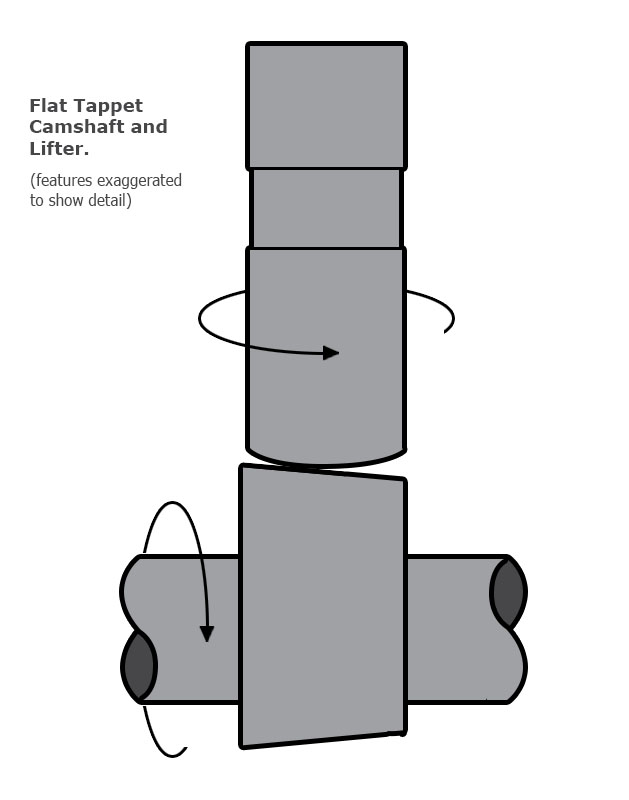

In reality, flat tappet lifters are not flat. They actually have a slight crown on the face. The camshaft lobe is machined with a mild taper. This causes the lifter to spin as it rides on the lobe and ensures even wear on the two surfaces.

Flat tappet cams are widely used, perform very well, and are more affordable than a roller cam.

When changing cams, the flat tappet lifters will need replaced. Follow this link for details on replacing lifters.

Roller Lifters

Lifters for roller cams feature a wheel supported by needle bearings and an axle. This wheel is attached to the bottom of the lifter body. The lobes of roller camshafts are machined perfectly flat. Roller lifters are linked together, or anchored somehow, to prevent them from spinning.

Roller lifters minimize friction which provides more power.

This design wears less, which leads to longer life. Roller lifters also allow for steeper cam lobes. In other words, they allow for more “area under the curve.”

This means the valve opens faster and remains at a higher lift for a longer period of time. This lets more air and fuel into the cylinder, which provides more power.

When changing cams, roller lifters can be re-used. Follow this link for details on reusing lifters.

…

This is another in a series of weekly Q&A Mailbag sessions with Summit Racing‘s tech department, in which there are hundreds more. Click here to see them all.

Very simple but effective explanation. I knew of the lobe profile difference but didn’t realize that the flat tappet cam was angled at the top of the lobe.

Did not realize the roller cam was much better than the flat top cam learn something good here thanks A lot

It should also be noted that each uses different materials for the camshaft and may require a special distributor drive gear where applicable.

Roller cam/lifters has more parts therefore are more prone to failure. Have seen lifter roller wheels lock up, wash out cam Dodges, Chevrolets. Dod engines with lifter activation/deactivation is another piss poor design that is making engine failure before it’s time way to common especially with high tech engines that are in use today.

Agree 100% The less parts the better.Frequent oil changes with zinc and your flat tappet can will last as long as the rest of your engine parts.

I agree 100% also. My first car had a flat tappet, my second car had a flat tappet, and my present car has a flat tappet. I have had no problems at all, indeed, they lasted forever if you use high zinc oil.