Q: Do I need a high-volume or high-pressure oil pump?

…

A: When buying an oil pump, you have a few options. The right pump for you depends on how your engine is built and how it’s used. The basic rule is 10 psi of oil pressure per 1,000 rpm at normal operating temperature.

For example, if you’re highway cruising at 2,500 rpm, you should have 25 psi. At idle, the same engine might have 10 psi or less.

Standard Oil Pump Basics

A standard oil pump will meet or exceed OEM specifications. Standard pumps are fine for most engines. It will provide enough flow and pressure for stock to moderate performance engines.

High-Volume Oil Pump Basics

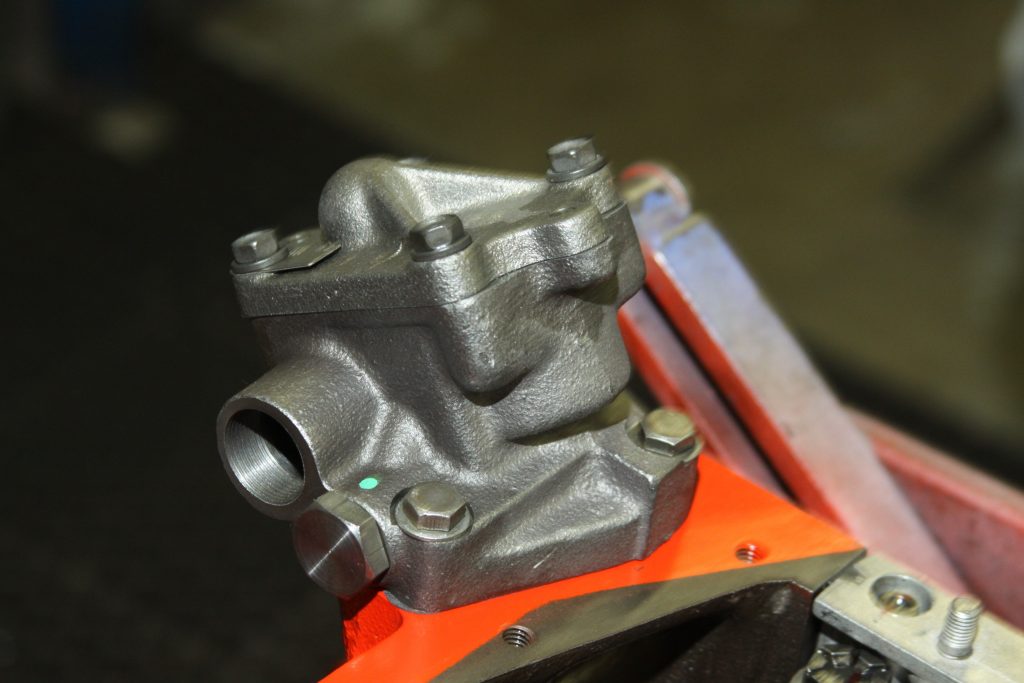

A high-volume pump will push more oil through the system. It has larger gears to move more oil per revolution.

These pumps are good for performance engines with larger bearing clearances. The added oil will help maintain oil pressure and carry away heat.

A high-volume pump may also be required to lubricate add-on engine parts, including:

- External oil coolers

- Remote oil filters

- Camshaft phasers (Variable Valve Timing)

- Superchargers and turbochargers

High-Pressure Oil Pump Basics

High-pressure pumps have a stiffer spring in the bypass valve. This allows more pressure to build before bypassing the oil back to the pan.

These pumps are required for performance engines that turn high rpm. If you are racing at 7,000 rpm, you need 70 psi. With some pumps, you can change the pressure relief spring to raise or lower the pressure.

High-Pressure, High-Volume Oil Pump Basics

A high-pressure, high-volume pump has both larger gears and a stiffer bypass spring. These pumps are only required for high-performance race engines.

Notes

- A high-volume pump WILL NOT suck the pan dry. Clogged oil drain-back holes and poor oil control will.

- Windage trays and crank scrapers help to prevent this.

- High oil pressure WILL NOT “wash out” your bearings. Excessive heat from low oil flow will overheat and destroy your bearings.

- This is usually caused by bearing clearances that are too tight.

…

This is another in a series of weekly Q&A Mailbag sessions with Summit Racing‘s tech department, in which there are hundreds more. Click here to see them all.

Thank You for the information. I have always wondered what the difference was.

Thanks.

Good info.

Why didn´t you mention the much bigger power need of the High Vol. Pump? I mean power to rotate the gears&make pressure.

It’s not nearly as much as used to be thought. (power lost on higher pressure/volume pumps)

High volume/high pressure pumps can also help keep pressure up if the engine is subject to low RPM’s, such as in heavy vehicles with manual transmissions.

Great info ,confirmed my long held theory on this subject ! Thank you !

Such an interesting information.

You have done great work. Thank you for this information.

The pressure valve does not return oil to pan . It cirkulates oil in pump until it can be passed on into the system .

Hey i have a stock crate 350 with a high volume pump oil and i am using 10w 30. Now the problem that i am have is that i put a mechanical oil gauge in my truck because why not,well when i installed it at cold start i have 50 psi of pressure then at worm temperature at idle its at 16 to 18 psi at 700 to 750 rpms an diveing at worm temperatures going 45mph at 1500 rpm its at 30 to 32 psi and going 60 to 65 at 2000 rpms the oil pressure i at 36 to 38 psi. Now at 3000 rpms or higher it will go to 40 pis an stay there.when i rev the engine at a dead stop the oil pressure goes to 40 to 40 to 45 psi at 4500 rpms plz let me know if this is normal for a crate 350 with a high volume oil pump with 45k on the motor.

well everything that i have to tell you isn’t good…this is way too low for my liking…having built over 1000 engines as my time as a shop owner. i have kept up commerical fleets and when a engine starts doing this you almost always end up totally rebuilding the engine to correct the problem…in a few cases you can install a high volume oil pump and buy your self some time….;which is where you are at now…but the usual problem here is too much bearing clearance……replacing all your main bearing/rod bearings/and cam bearings /with a good high volume oil pump (in your case a melling hv55) should cure your problems…..make sure you check your crankshaft shaft as well…..a worn crankshaft also causes this type of oil pressure problem..so if this is the case turn it or replace it……also if you are doing the whole engine rebulid…;take your oil plugs out of the block before you hot tank your block…after you get it out of the hot tank make sure to blow air back and forth through these journals to remove any debris that might be in them…… and that’s how you fix oil pressure….