So you’ve just finished your meticulous engine build and you’re nearing the point of first start. Getting oil to all the components quickly is a must. Old school engines made this job pretty easy. Just stick an oil pump primer in the distributor hole and hit it with a drill.

Late model engines with their crank driven Gerotor-style pumps make this job tougher, but pre-lubing the engine is no less important.

One way to get the job done is with a pre-luber kit.

Simply fill the tank with oil and adapt it to your block’s oil cooler fittings or oil pressure sending port. Pressurize and turn the valve and it will deliver pressure to the oil galleries

If you build a lot of late model engines; a fluid transfer pump works well for LS, Hemi, and modular engines.

Although both of these systems work well, they are a little pricey and the tanks take up a lot of space when not in use.

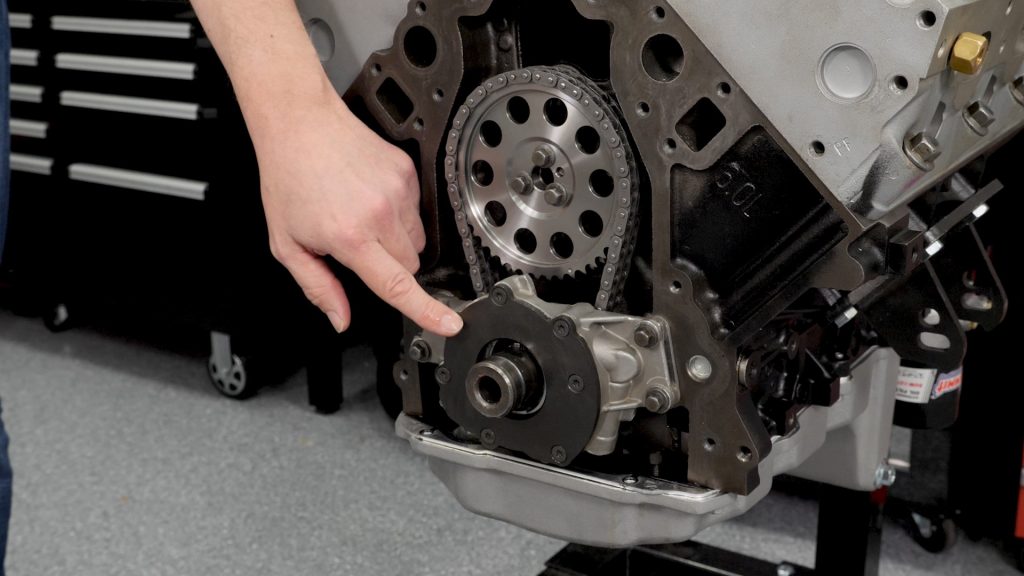

Another option are the new Summit Racing-brand oil pump priming sockets for LS engines and late model Hemi engines. They are intended for use with aftermarket timing gear sets where the oil pump drive gear is separate from the lower timing gear.

NOTE: The factory gear sets use an integral gear, so you’ll need a conventional pre-luber tank for those.

These new primer sockets are simple to use.

- Install your timing chain set without the oil pump drive gear.

- Slightly wobble and twist the front of the socket until it engages the Gerotor.

- Spin the socket clockwise with a 3/8” drive-adapter and drill. It takes about 30 seconds for the oil to start seeping from the pushrods.

- Turn the crank 180 degrees and prime again. Do this two more times to ensure every component sees oil.

The socket works with the front cover off or already installed. With the cover off, it’s easier to install the oil pump drive gear after the engine is primed.

The downside is that a little oil will pour out of the pump into your engine stand’s drip-tray. Afterward, the front cover can be aligned easily enough, but bolting the pan in place is more complicated because it’s full of oil.

NOTE: Remember to use RTV at the four corners.

With the cover aligned, it and the oil pan can be bolted down while on the engine stand. No mess at all, but you’ll need to align the pump drive gear with the oil pump rotor (which floats in the pump) after the cover is installed.

We recommend leaving the front seal out to ease the installation of the drive gear after the priming operation is complete.

Tech Tip: Rotate the crank until the key is at 12 o’clock. After priming, clock the oil pump rotor so a slot is centered over the keyway as shown. Then gently tap the drive gear into place. Clocking and installing the gear is easier without the front seal installed.

You may find the drive gear goes past the Gerotor, but won’t bottom out against the lower timing gear. If so, it’s hitting the back face of the Gerotor’s chamber. This is due to the oil pump not being centered on the crank snout.

To remedy this requires taking the front cover off and aligning the pump. This can be done with shims or by floating it with finger tight bolts and turning the crank several times so the pump can find its center before torquing to spec.

During the first start, your engine’s bearings and valvetrain components will be bathed in oil and thank you for taking the extra time to do it right.

Check out this video for more information, where you can see this tool and process demonstrated on an LS engine build.

I’m very old school(50years+) when I assemble an engine gas or diesel I appply plenty of STP onto every contact surface. With no spark plugs installed or injectors(diesel) I’ll spin the engine over by starter until I get a good stream of oil flow out of the oil pressure sending unit port.

Never had any problems,never lost an engine.

“KEEP MOTORING”

Sometimes STP wont let the rings seat properly. Ive seen it happen.