The fan clutch is an important part of your cooling system.

Its drive shaft attaches to the water pump. Then, the fan attaches to the clutch housing.

The fan clutch’s job is to control when the fan switches on and off. It provides airflow when needed and reduces drag on the engine when not needed. This improves power and fuel economy.

The fan disengages when:

- The engine is cool

- The vehicle’s speed forces air through the radiator

The fan engages when:

- The engine gets hot

- The vehicle isn’t moving, or moving slowly

How does it work?

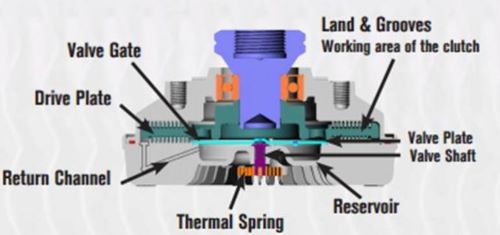

Most fan clutches are filled with a silicone-based oil. The oil is held in an internal reservoir when the fan is disengaged.

To engage the fan, internal valves open and allow the fluid to fill the working area of the clutch. This creates friction between the drive plate and the housing, causing the fan to spin.

To disengage the fan, the valves close. The fluid is kept in the reservoir. This reduces the friction and allows the housing and fan to spin independently of the shaft.

How are the valves controlled?

This is where the clutch styles differ.

Fan clutches can be non-thermal, thermal, or electronic.

Non-thermal fan clutches are rpm-dependent. Centrifugal force pushes the fluid against the valves. At low rpm, the valves are open, allowing the fluid to flow and engaging the fan. As rpm increases, so does the centrifugal force. The force closes the valves and keeps the oil in the reservoir. This disengages the fan.

…

Thermal fan clutches use a bi-metallic spring to sense temperature. When the engine is cool, the fan is disengaged. As the temperature increases, the spring rotates the valve plate and allows the fluid to flow. This engages the fan. As the temperature drops, the spring relaxes, rotating the valve plate back. This stops the fluid flow and disengages the fan.

There are three levels of thermal fan clutches:

- Standard duty thermal fan clutches turn the fan at 50-60 percent of the water pump speed when engaged.

- Heavy duty thermal fan clutches turn the fan at 80-90 percent of the water pump speed when engaged. This provides more airflow for better cooling.

- Severe duty thermal fan clutches also turn the fan at 80-90 percent of the water pump speed when engaged. However, they have a larger working area. This helps them run cooler and last longer.

…

The last type is an electronic fan clutch. These clutches operate the same way as a thermal clutch. However, the valves are controlled by a signal from the vehicle’s computer.

NOTE: A clutch fan is never fully disengaged. Even when disengaged, the fan will turn at 20-30% of the water pump speed.

Which type is the best?

The best type of fan clutch is the one designed for your application.

Using the wrong parts could result in poor cooling, excessive noise, reduced fuel economy, and/or fan clutch failure.

For better cooling, you can upgrade from a non-thermal or standard duty clutch to a heavy duty or severe duty clutch.

However, replacing a thermal clutch with a non-thermal clutch is never recommended. An electronic clutch should only be replaced with another quality electronic clutch.

…

This is another in a series of weekly Q&A Mailbag sessions with Summit Racing‘s tech department, in which there are hundreds more. Click here to see them all.

[…] The fan clutch is an important part of your cooling system. Its drive shaft attaches to the water pump. Then, the fan attaches to the clutch housing. The fan clutch’s job is […] Read full article at http://www.onallcylinders.com […]

Very interesting and well done.