I want to build the cheapest, least expensive small-block 350 Chevy that can make around 400 to 450 horsepower. How would I do that? I have a 350 Chevy truck engine short block with a one-piece rear main seal. I really don’t know what it was originally in but I’m pretty sure it was a truck. I’d like to put this engine in a ’69 C-10 pickup to terrorize the streets. How much power could I make? — B.C.

…

Jeff Smith: Before we get started, let’s just say that the terms “lots of horsepower” and “cheapest” are at opposing ends of the same discussion.

It’s not easy. Frankly, the easiest way to make 400 to 425 horsepower would be to buy a 5.3L truck engine and put on a carbureted intake manifold, a 750 cfm Holley carb, headers, and stick in a mild hydraulic roller like Summit’s Stage 2 truck cam with 218 degrees of duration.

That’s not what you asked, but that would be the easiest way to achieve 400 hp. Of course, adapting an LS to your truck would be expensive and not part of your plan. So now let’s address your question.

It’s not easy to make 400 hp with a basic 350 Chevy using stock heads.

The advent of modern engines that make 400 hp or more has colored the reality of the past. In our experience, you must have a decent set of cylinder heads in order to make 400 hp on a basic, low-compression 350 c.i.d. small-block Chevy.

Let’s start by assuming (here we go) that your short block is in decent shape. That means you can’t feel an edge at the top of the cylinder wall from bore wear. If you can feel a ridge, then you are wasting your time to attempt to make power. A ridge of any thickness means the cylinder bore is worn and the rings won’t seal and all your money spent on good parts will only pressurize the oil pan when that cylinder pressure leaks past the rings. But we’ll play along and assume the short block is sound.

The biggest item that will improve power is a good set of heads. The more air the heads can move through the combustion space, the more power the engine will make. But aftermarket heads cost money that you don’t want to spend. The best iron production cylinder head that Chevrolet ever produced was the Vortec that came on truck engines from 1996 up through when the LS engines first appeared in 1998.

The Vortec head is a bit of an offshoot from the traditional small-block Chevy head. It demands its own, specific intake manifold and features smaller 1.94/1.50-inch valve sizes and a compact 64cc chamber.

This smaller chamber helps add power by adding compression. You can still find these heads in the junkyard but be careful as engines with a long service life can suffer cracks that make them unserviceable.

Let’s start with the first benefit to using these heads — the smaller chamber. Nearly all traditional heads for a mid-70’s and later 350 c.i.d. small-block came with 76cc chambers. This was done to reduce compression so that Chevrolet could achieve the emissions requirements.

With the smaller 64cc chamber Vortec heads, this means more power. Let’s assume that your 350 comes with typical four-eyebrow pistons that measure about 0.020-inch down from the deck.

If we use a stock composition gasket at 0.041-inch thick with a 76cc chamber, we end up with a compression ratio about 8.5:1. In most production 350 Chevys, this is actually high. Loose production tolerances often limit these engines to barely 8.0:1. By simply adding a 64cc chamber head, the compression jumps to 9.6:1. That’s worth 10-12 hp with no other changes.

But the real beauty of the Vortec is its additional airflow even using 1.94/1.50-inch valves. The best thing to do here is make sure the valve seats are in decent shape and seal properly and leave them alone. Our flow bench tests from back in the day reveal these heads to flow around 230 cfm at 0.500-inch lift at a time when a production iron small-block head generally couldn’t flow 200 cfm without porting. Plus, the Vortec will add 20 to almost 30 cfm in the mid-lift valve positions like 0.300-inch and this is where the additional cylinder filling really crams the air in for a mild street engine. Peak flow numbers are only achieved at one point, but mid-lift valve lift occurs twice — once on the way up and again as the valve is closing.

By adding the Vortec head, we have the makings of a more powerful engine with more compression and airflow.

Next, we add a camshaft. Your engine may be equipped with the fixtures in the block to allow a hydraulic roller cam, but since we don’t know if this is the case, we’ll assume that it is a flat tappet engine. Since your budget is limited, that points us to a flat tappet hydraulic cam package.

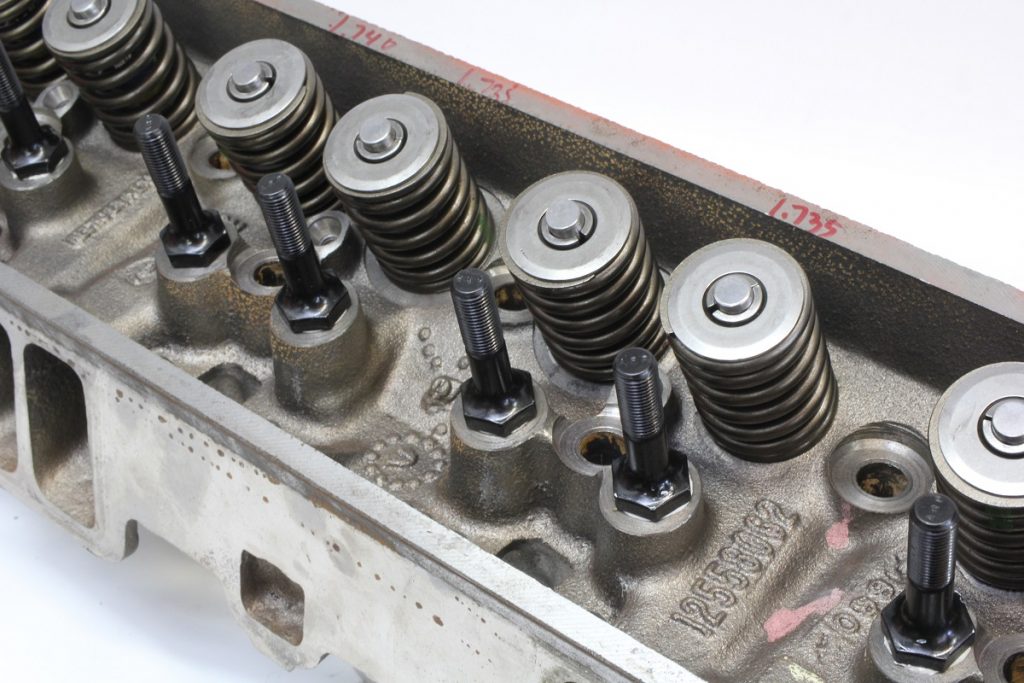

Back when we were testing these combinations, our favorite was a conservative cam from COMP called the Xtreme Energy 268H. With advertised specs of 268/280 it offered 224/230 degrees at 0.050-inch tappet lift with valve lift numbers of 0.477/0.480. This added valve lift creates a problem for those Vortec heads unless changes are made to either the valve springs or machining the heads to improve retainer-to-seal clearance. So let’s touch on that.

The Vortec heads use a very tall valve guide boss. With stock springs and retainers, there is only about 0.475-inch of clearance between the bottom of the retainer and the top of the valve guide seal. This limits valve lift to an absolute maximum of 0.450-inch lift. There are two possible remedies to allow additional valve lift.

The first involves machining the valve guide height by using a COMP cutter (PN 4726) and arbor (PN 4732) and a ½-inch drill motor or drill press. Cutting the height down by roughly 0.050-inch or more will be sufficient. This also cuts the guide diameter down to use a 0.530-inch diameter seal, which means new seals are required. If you are considering this, practice using this tool on a junk head first to make sure you get all the dimensions correctly cut. There have been reports that some of the cutters may make the guide O.D. too small for the 0.530-inch seal.

Of course you could pay a machine shop to perform this work, which isn’t that much more than doing it yourself and may be the best solution if you don’t have experience with machine tools.

When we performed this little machining exercise, the cutter worked perfectly and produce sufficient clearance for a 0.500-inch lift cam.

If you decide to change springs, COMP offers a 26915 beehive spring and matching retainer that will produce a little more clearance to allow up to roughly 0.500-inch of valve lift. We haven’t checked that lately so if you go this route, it would be worthwhile to verify those numbers.

The Vortec head also requires several components that are different from the traditional small-block Chevy parts list. Let’s start with these heads require guided rockers that have two small ridges that straddle the valve stem tip. This was done to eliminate the need for pushrod guide plates. The Vortec head also requires its own unique intake manifold, centerbolt-style valve covers, and spark plugs.

For your application, we’d suggest an Edelbrock Performer RPM intake. Remember that this will also require a Vortec style intake gasket.

The combination of the heads, Xtreme Energy cam, Performer RPM manifold, 750 cfm carburetor, and headers will push your 350 into the 410 to 420 hp range — again assuming the rings are in decent shape.

Of course, if all this chasing around looking for a set of used heads and then spending time and money modifying them seems like a lot of work, Summit has a solution as a brand new pair of iron Vortec castings that are fitted with all new valves and springs.

The Summit Vortec sports a 175cc intake port, screw-in rocker studs, the same 1.94 / 1.50-inch valve sizes and a 67cc combustion chamber. Flow numbers are better than the production heads and the heads are capable of accommodating a 0.500-inch-plus lift camshaft. For the money, this might be the simplest and easiest way to get to your 400 to 450 hp goal.

[…] I want to build the cheapest, least expensive small-block 350 Chevy that can make around 400 to 450 horsepower. How would I do that? I have a 350 Chevy truck […] Read full article at http://www.onallcylinders.com […]

For this cheap build, would it be the same numbers if I stuck with the efi instead of going carbureted?

I’m surprised that one of the many top end kits wasn’t recommended. Yes, they’re pricey as an initial investment. On the other hand, any Vortec head that I’ve seen come from a typical (there because it’s used up, not a low mile wreck) junkyard vehicle is pretty much guaranteed to be cracked. Time spent chasing good junkyard parts is also money spent. The top end kits,as I’m sure you know, have parts matched to work together, no guessing it this will work with that.

What’s a good top end kit for a sbc 406 with a 555 lift cam?

Budget friendly of course

Why does nobody ever give any attention to rods in Chevy engines? I could build a 400hp 327 Chevy using stock heads and cam with efi from a vortec truck 350. The key is in the road length. You need a rod length of about 1.9 to get easy top end on a has engine.

Rod length of 1.9? I thought the typical 350 sbc Chevy rod length was 5.7″.

Perhaps you mean rocker ratio.

I can vouch for your recommended combination. The sbc’s for street that I have built differ only in that the cam is the next more duration comp cam. They were used in Camero’s and performed excellent.

A 350 ABC motor is a 5.7l not a 5.3l that’s a 305 or 307.

sbc

I believe the intent of Jeff’s comment was how to make 400hp, not that a 5.3L has a 350CI displacement. A junkyard 5.3L (323CI) if found in decent shape is easier to make horsepower due to the higher flowing head, but the expense of the other needed swap parts can make the overall costs go way up.

Thaks Carl for making that more clear. Yes, that was the intent of the comment – I should have been more clear that a 5.3L engine is not the same displacement as a 5.7L 350 Chevy. Y intention was to point out, as you mentioned Carl, that a smaller displacement engine can make more power using the highly efficient LS version heads.

Wrong a 5.3 motor is a 328 cid

The 5.3 he was referring to is the LS 5.3, not a 305 or 307. that why he alluded to the fact that this swap can be more expensive and require more parts.

A liter is apprx 61 cubic inches. A 5.3 L exact would be 323.3 cu in. The gentlemanreferred to the Ls 5.3 L as the La heads have good flow and a steeper valve angle, as in Buick 350, 455 had 10° Valve angles n 315 hp rated Buick 350 wave goodbye to Chevy 350/350hp at 125 mph, both being automatics, the Buicks valve angle allowed greater top end Bout 150 mph with good points n plugs set right n decent wires. Good distributor great wires n headers would see 160 in GS 350 trim, 1970. 3.800″ boreX 3.850″ stroke, they were sickening off the line. You needed lots of sticky rubber to get traction. Think Ls came initially with 15° valve angle. 307 chevy is 283 bore x 327 stroke as in 3.875″ bore X 3.250 stroke, 305 is 3.736″ bore X 3.480 stroke. Always yank old crap apart acid dip, sonic, mag check block, new cam bearings, freeze plugs, align hone crank bore . 020 over or what it takes to clean up cylinders, bore, hone WITH torque plates, crankshaft (if must reuse, now may be a good time to think internally balanced 383/6″ rod if its 2pc. rms) turned n micropolished if using stock rods get good arp bolts, resize, balance rods, big ends, small ends, new hyper or forged pistons depending on what the purpose, pistons balance matched, crankshaft balanced with new balancer n flexplate supplied to machine shop, as also 1 piston’s ring set( ductile, ductile plasma moly, crazy gentle on cylinder walls,) n rod bearing to determine bob weight. I like 1/2 gram balance. I like Clevite 77 tri- metal bearings, but old school, maybe new aluminum bearings are worth looking into, but im not saying go there, just look into options, rings, seals, bearings, pistons, n rods,NOT where you wanna be a tight ass, goes for camshaft also n valvetrain. Engine building is a commitment but youre the one gonna get that 400k miles if maintained correctly. If cash strapped say yes to some overtime, you will arrive there at some point n your motor if assembled correctly will not be a flash in the pan, but a dependable friend. as in “damn, are you still driving that same engine around “

I have pretty close to the same setup, except I have a Victor Jr. with a Holley 750 vacuum secondaries and Dart (world products) SR torquer heads with 2.02/1.6 and 76CC chambers. like the article, with the head gasket I figured I lost 1.5 compression points so I swapped out gaskets for steel shim .015 thick. the cam is a lunati bracket II. This is going into a Datsun 620 truck about 2350 lbs. I’m being on the safe side and thinking somewhere in the 12s but my friends say 11s easy.

Your engine is nowhere close to the same setup!!!

It is completely different…

Different intake, different heads, different cam, even a different compression ratio…

I think you just wanted to brag about your engine…

Whoever built it for you is probably proud of their work!!!

How big a thumpr cam can i put in a 91 l-98? Vacuum not an issue going in a ratrod

these long ramped, long advertised/ short . 050 duration liw lift cams came about in an era when high test was listed as 104 octane on the pump, however it may be as much as 116 octane. The 104 meant 104 or above. These cams were gentle on the valvetrain. Now I have just (being old school )moved into the 54 or so degree camp, 60+ degrees between . 006″ and . 050″ lift figures really where i like to be as in 280° advertised, 220°@.050″. not 280°advertised, 236°@.050″ that requires more seat and over the nose valve spring pressure, n thats not free as in parts cost, or the energy the engine expends to compress those stouter spring loads. Now the thumper seems to be easy on the valvetrain as i remember BUT there is so much more out there that would be more powerful while being super efficient. As in taller gears, higher stall torque converter, extra gas, etc., etc., not needed. N remember unless you talking stroker, all that overlap and longer exhaust duration will hurt low end torque. Thats why Buick, Pontiac, N Olds used them(along with wider LSAs) to bleed off some bottom end cause tires went up in smoke at the touch of the pedal. Now i think Thumper got 108° Lobe separation angle which will enhance cylinder pressure, n all that duration gotta give some top end but why blow all that gas out the exhaust.

What is the part# for the Summit vortex heads featured in this article?

SUM-151124

Wow! It’s a good thing to know about these things. Thanks hammtreeservice.com/

Ohh! Thanks for making this blog well updated. usps change of address online

It’s a great article! thanks for sharing RD Medical Products – Index

Why does nobody ever give any attention to rods in Chevy engines? I could build a 400hp 327 Chevy using stock heads and cam with efi from a vortec truck 350. The key is in the rod length. You need a rod length of about 1.9 to get easy top end on a gas engine.

Actually Josh, this is a common misperception. David Reher of Reher-Morrison racing engines and an NHRA Pro Stock champion has done rod length dyno tests and came to the conclusion that rod length has a near-zero affect on power. It will move the power curve around slightly but very little else. Rod length was a big controversy about 30 years ago in the magazines and urban legend has evolved from all that nonsense. Bottom line is connect the crank to the piston with whatever rod length fits and is strong enough to survive. There is no power to be had from the rod length to stroke ratio. It’s just a number.

Exactly. A popular misconception with building a 383 small block is that using a 6.0″ rod will make more power than the 5.7″ rod due to the increased dwell at the top of the combustion stroke. This has largely been disproved, although I know several people who’ll use 6.0″ rods on higher revving engines in the 7K RPM range. All in all, if there is a difference, it’s no more than one or two HP at best and the same with Torque.

Rod / stroke ratio is meaningful. Lesser angularity achieved with a longer rod decreases the side loading of the piston on the cylinder wall on the thrust side. If this isn’t a plus, especially in factory side loaded problem engines like the 400 SBC, with its 1.484:1 R/S ratio I don’t know what is. Also theres the physical mechanics of piston speed in regards to rod length on the up and down strokes int, comp., power, exh.. Forget the insignificant hp gains

One thing I did not see mentioned if the pressed in studs would hold .500 lift or what they would hold. I know in some old style heads I have seen the studs pull out with just a very mild cam. I know the newer style head where better about that not happening but still wondering what the fail point is.

Dan – you make an excellent point, but the real reason the pressed-in studs will pull out is due to spring pressure. It’s simply leverage. So higher spring pressure will yank the studs out. So if there is a plan to use springs with a seat load of over say 120-125 pounds and commensurately higher loads at max lift, then a screw-in stud is mandatory. Better to do this before the heads are bolted on the engine since drilling and tapping is not something you want to do with the heads on the engine.

So I’m trying to rebuild a Chevy 305 wat would be the best cam and head and crankshaft

5.3 is what is considered the modern “327”. Although, it’s actually 323ci.

They posted my reply in the wrong place. But, I do have experience with building some 305’s. If your Chevy 5.0 (305) came with double hump heads then make sure all components are working properly and are in real good shape. Put AT LEAST a triple-angle valve cut(a4 or 5 angle cut is even better), then the CompCams Xtreme Energy 268H cam (people refer to it as a .480 lift/ .280 duration cam) and lifters {they’ll come as a kit, actually you can get the cam,lifters,double-roller timing chain,pushrods,springs,valves w/keepers and seals all in a kit}, then a Weiand mid-rise alum intake and Holley 650cfm single pumper w/vacuum secondaries, a HEI distributor/coil combo (65,000 output), a set of at least 9mm copper core wires (JDM has 10.5 core wires!!!) and new E3 triple-fire spark plugs and Hooker Long-tube headers (depending on what it’s going in, you may need “sure-fit” Hookers or Hedman Long-tubes) !!!

My Black 76 Camaro ran like a scalded dog w/ 3.08 gears. My speedo went to 130….. my Camaro went beyond !!! I later put 3.55 gears in and the TH350 (both sets of gears) and it still pegged the speedo but it had much better jump w/3.55’s. I even kept the rocker arms, but I’ll guarantee a new set of CompCams 1.5 (1.6 would give even more valve lift & they cost the same) full roller-rockers compalloy, alum. or even stainless steel(that look chrome) will fill your heart (but mostly your ears) with joy !! Mine sounded incredible !!!

I’m building a 383 SBC for my pontoon to replace the existing V6 weakling currently installed. This boat will be for idling around the lake (500-1500 RPM) or flat out grudge racing. No skiing or tubing, thus, no low speed torque or “throttle response” requirements. The only part I have so far is a 4-bolt iron block which has been bored .030 and decked about .005. I see that a very popular rotating assembly is the Eagle B13055E030 which includes KB flat top hypereutectic pistons with 7cc valve reliefs, decent rods and a cast steel crankshaft. Online CR calculator show this combo to produce about 10.4:1 or 10.5:1 static compression ratio with 64cc heads. Cam will probably be Comp Extreme Marine (XM270HR or XM276HR) with 112* LSA to keep the idle reasonable. I have not identified the heads yet, but they will be aluminum. Intake is Performer RPM and Holley 750. Mercruiser recommends a 160* thermostat. I have scheduled dyno time to establish timing and jetting.

My dellema: I don’t want to give up horsepower with a lower static CR. Should I go with the 64cc heads, flat-tops and 93 octane pump gas (jetted fat) or go with the 64cc heads, 12cc inverted dome or 18cc inverted dome yielding 9.8:1 and 9.4:1 static CR respectively. Online calculators have show the flat-top combination to yield a dynamic CR somewhere in the 8.5:1 range. Next question is intake runner volume. 150cc to 230cc is available. I’ve built a 406 SBC with Dart PRO-1 heads (220cc runners) and it didn’t lack for anything. For the 383 I’m thinking 200cc or 220cc. Again, think flat-out or idle. Drive is Mercruiser Alpha-I GenII with synthetic lube and 21p wheel. I’ve had this same combo behind a 450HP big-block (23p wheel) and had zero issues. I’m looking for recommendations.

5.3 is what is considered the modern “327”. Although, it’s actually 323ci.

Whatever ci the 5.3 is I’d bet that Jeff knows how to figure bore & stroke! Anyway I’m going with the “modern 327” I love 327’s! Thanks Jeff for the information it’s very useful & I’ll also bet it’s spot on

Ok my name Nick and deaf. I’m good hand tools . I would like to get catalogs book and send to me pls

Hey Nick, thanks for reading! If you’d like to request a Summit Racing catalog, CLICK HERE.

Awsome article…. Can u e-mail it to me??? At [email address deleted, ed.]

I don’t know how to print or save this article…

But I can rebuild a small block Chevrolet blind folded… Lol

Sure thing Don. I’ll send off a PDF here in a sec…thanks for reading!

Full of useful information. Easy to understand. Thanks for the tech support

I have a 96 350 vortec roller block ZZ4 I need to know if I can use good aftermarket aluminum heads non vortec because I have a edelbrock performance intake non vortec with a 64ccor 67 202 and its going to be a full roller motor and I put in a muther thumper comp cam what aluminum heads should I buy that will not brake the bank

Hi Jeff ,. My name is Jeff also . But my question is 1988 Chey C10 305 tbi, auto , pb ac ,2dr , well the Engine just is getting real tired I’ve kept it up ok but I’d like to replace it soon right back to just stock this motor that’s in has blow by so it’s. Got to to be replaced I like a 350 vortex if I could the truck itself in pretty good shape. No rust yet. I live in mi

I have a 327 bored 30 over. All new pistons rings cam. Everything. Stock. Heads are rebuilt stock heads. I disappointed in the power. It in a 72 chevy c10 pickup. 4 speed. Any suggestions?

How will this setup work with a 383

Good job..verry well explained.

What length should the pushrods be for this build?

Ok this is what I do screwing studs guide plates a 1.460 valve spring dual spring bull hog the intake can I run a 2.055 a flat Mill they had anywhere from 35 to 40,000 on a 377 I have 11.4 to 1 compression ratio

Hello Jeff

I have my eyes on a 1965 Chevy El Camino . It has a straight body, is primer coated and scuffed but not painted, and has all the chrome trim pieces mostly ready to be put back on. Interior is all there, upholstery not torn. A 350 crate motor was added 10 years ago.It has a Edelbrock Victor high rise and a 750 Proform carb on top. Some brand of black headers.Hooked up to a Muncie 4 speed.

Any rough idea on a fair selling price at this time, and also any tips on long term ownership. My intention is to have a reliable turnkey cruiser for long drives and vacations, not for the drag strip. All the best, Robert

[…] Quote from the source: … […]

Could I use these ideas for gaining horse power on a 383 stroker bottom end instead of a standard 350? If so, what kind of numbers would I be looking at? Is there anything different I should do if I use a 383?

I have a 99 vortec 5.7 from a Tahoe “r” vin code I picked up to rebuild for a 46 chevy truck project. Plan on running a t56 trans behind it. Budget hp build. What to not run carb but tbi setup to give it a more classic look but be more efficient. Thinking fitech efi. Run the vortec heads with behive springs. What cam should I use and intake to get in the 450 hp range.

Jeff,

So if that “brand new pair of iron Vortec castings that are fitted with all new valves and springs” The COMP cutter and drill work is not needed?

[…] https://www.onallcylinders.com/2020/06/05/ask-away-with-jeff-smith-getting-400-hp-from-an-old-small-… […]

I have a 1997 Chevy 1500 EXT. Cab, 2wd it has 90k on the original 5.7 Vortec! I am wanting to do something like you just wrote about! Increasing HP to 400-500. Can a supercharger be added to the work you described? This truck is all stock including original exhaust, only thing I’ve added is 20” Chrome wheels and tires! I would also want a 3.73 geared rear end!

This truck is immaculate with no rust, always garages! Wish I could send you a photo!

I’m building a mild sbc 350, 400-450 horsepower, in a 79 vet, stock rearend is 3.36 posi. I got ahold of a Torker II intake for hood clearance, is this going to be ok for good street performance?

Alan

The Torker is an older and very short single plane manifold and not a good choice. Since hood clearance is an issue – look for a dual plane manifold that will fit. Even the old original Edelbrock 2101 Performer is certainly a better choice than the Torker for mid-range torque. The Performer is just a better manifold for what you are doing.