Q: I have a 1994 Ford F-150 with a 5.0L engine and factory mass airflow sensor. I just had the heads redone and installed a Trick Flow Stage 1 camshaft. I have spark and fuel, but it won’t start. Sometimes it acts like it wants to start if I twist the distributor to advance or retard the timing. I installed the distributor with cylinder number one at top dead center. As far as I can tell, everything is right. What am I missing?

…

A: Assuming you have installed the camshaft correctly, it sounds like the distributor is not properly installed, your firing order is off, or the harmonic balancer ring has slipped, making your timing marks inaccurate.

Start with a visual inspection and confirm that all your ignition connections are fully plugged in, grounds are clean and tight, and vacuum lines are properly routed. Also examine the balancer elastomer to see if it’s intact.

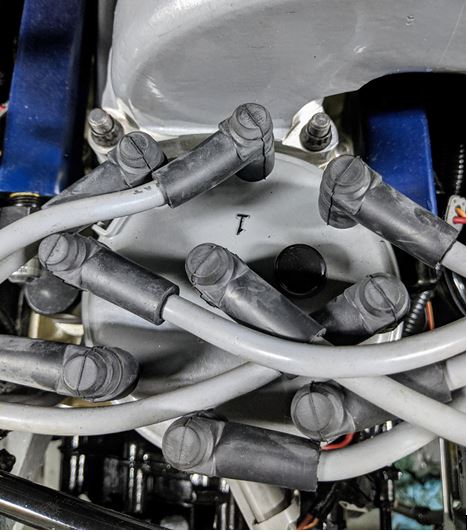

Next, inspect the spark plug wire routing.

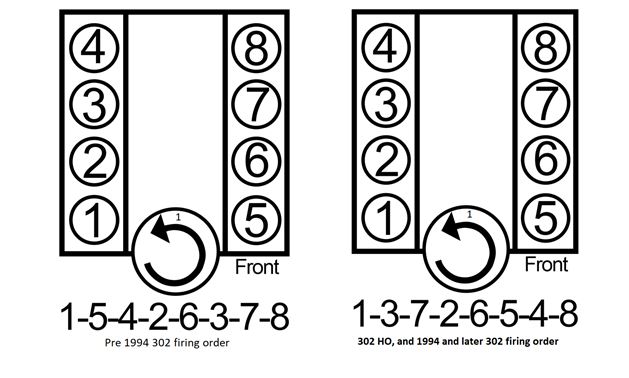

In 1994, Ford changed the firing order on the 302 trucks with mass air to 1-3-7-2-6-5-4-8 (same as the 351W or 302 H.O. engines) from the earlier order of 1-5-4-2-6-3-7-8.

Regardless of what’s listed on your truck’s emission sticker, the firing order will need to coincide with the Trick Flow camshaft’s H.O. firing order.

To verify the balancer ring has not slipped and you are working from accurate timing marks, compare the top dead center (TDC) mark on the balancer with the crankshaft keyway position.

On Ford Windsor engines, the crankshaft keyway is positioned at 12 o’clock when the number one piston is at TDC. To check this, remove the balancer bolt so you can view the keyway for the balancer. With the keyway straight up, the timing mark should be at 0°.

If it’s not within a degree or three the balancer has slipped and will need to be replaced.

Once you have established the timing marks on the balancer are accurate, you’ll need to make sure the piston is on the compression stroke before setting up distributor rotor position. Because the crankshaft rotates twice per engine cycle, the piston may be at TDC, but be positioned between the exhaust and intake strokes; this is known as being 180° out.

To verify the engine is on the compression stroke, remove the number one spark plug and place a finger over the hole. Carefully bump the engine over with the starter until you feel pressure building in the cylinder and then stop. This will get you close to TDC compression.

Continue to rotate the engine by hand to the 10° advance mark on the balancer.

With the timing at 10° before TDC on the compression stroke, install or check that the distributor is properly positioned. To accomplish this, install the cap onto the distributor and locate the number 1 stamping on the cap. Use a marker to draw a line on the side of the distributor cap adapter parallel to the number 1 mark on the cap.

This will be used as a reference for the correct rotor and distributor housing position. The number 1 cap marking is only present on electronic ignition caps—earlier points or aftermarket distributor caps may need to have the number one cylinder location marked on the cap with a marker or small piece of tape.

Remove the distributor cap and install or reposition the distributor so the mark placed on the adapter is oriented near 12 o’clock (looking downward from the front of the vehicle) and the rotor is aligned with that mark with the engine balancer still at 10° advance.

You should be able to pivot the distributor housing around in the 12 to 1 o’clock range and align the mark on the cap adapter to the rotor pointer. If the rotor is not within that range, lift and reinstall the distributor, engaging different distributor teeth on the camshaft drive to position the rotor correctly.

Gently snug down the distributor, remove the spout connector (located near the ignition module), and start the truck.

Using a timing light, set your ignition timing to 10° before TDC. Then, tighten the distributor hold down and reinstall the spout connector.

[…] Q: I have a 1994 Ford F-150 with a 5.0L engine and factory mass airflow sensor. I just had the heads redone and installed a Trick Flow Stage 1 camshaft. […] Read full article at http://www.onallcylinders.com […]

Very thorough explanation of everything. Thanks

I love the materials needed. Thanks coutureusa.com/

You stated that you had the engine on TDC. but was it on the compression stroke ? If not you could be 180 degrees off.

I love everything about this!http://www.lovingcareanimalhospital.net

Thank you for sharing this! https://www.midwestbreakfastco.com/

Great write up and pictures.

Mike yes this is your brother I got fast bikes you might want so if you get this message look me up I ain’t hard to find it’s worth it bro