Take your pick: Chain hoist or cherry picker.

That’s the standard when it comes to yarding out (and replacing and simply moving) an engine in your ride or around your shop. But how you hook the engine to the hoist is the next question.

The easiest way is to use the hooks many original equipment manufacturers bolted right to the engine. But over time many of those hooks have vanished. Yes, reproductions are available, but there are other methods to consider aside from bolting a chain to the cylinder heads.

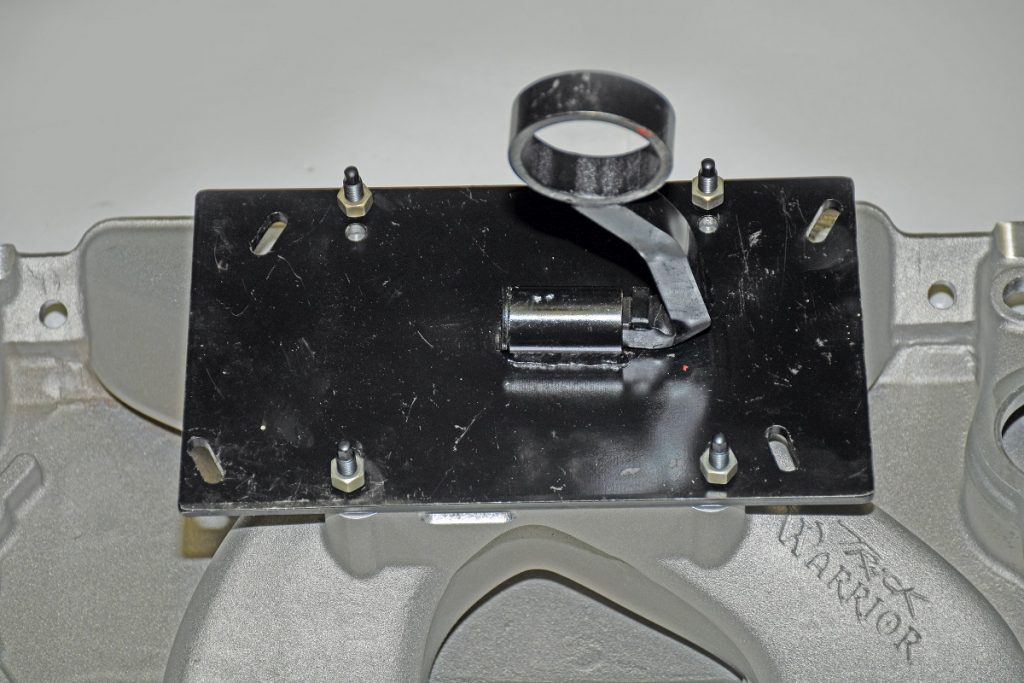

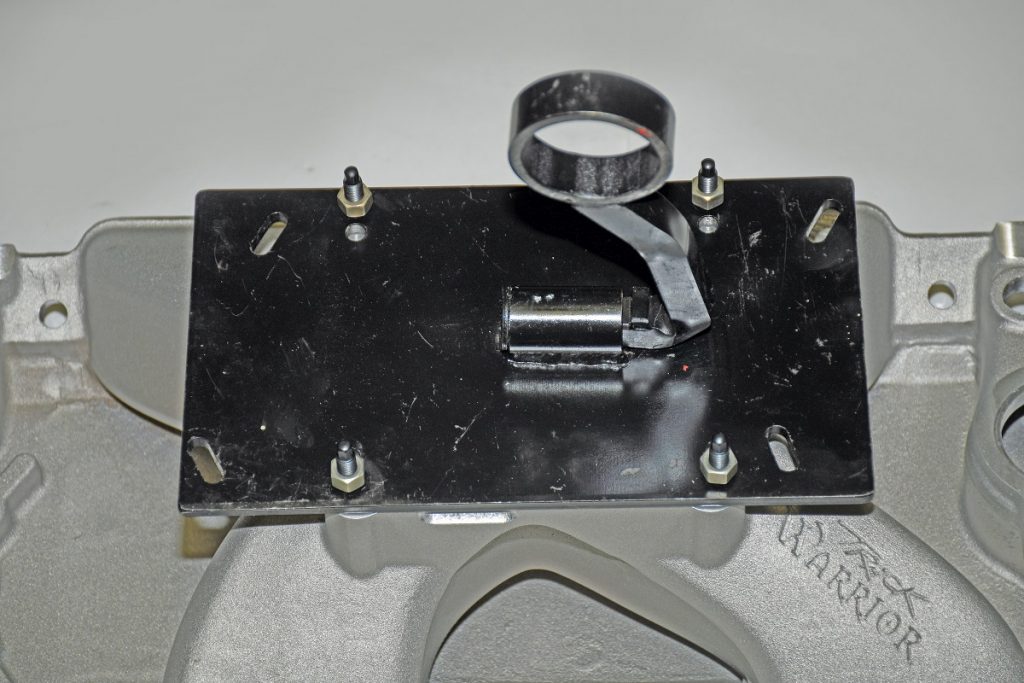

The most common cherry picker accessory is a lift plate that bolts to the top of the intake manifold.

Some folks might scoff at using lift plates, simply because they’re held in place by four puny 5/16-inch fasteners. But consider that a single Grade 5, 5/16-inch UNC bolt has an approximate yield strength of 3,300 pounds.

Multiply that by four and it’s easy to see that something like a cast iron Hemi isn’t going to rudely crash to the ground from using lift plates.

There should be more concern over the integrity of the intake manifold threads or even the manifold itself than there is for killing a fastener.

NOTE: Speaking of manifold integrity, it should be obvious that you shouldn’t use a lift plate on a sheet metal intake or on a heavily ported example (we’ll get into some solutions later).

A lift plate that this writer uses (and one that’s shown in the accompanying photos) is an old TPIS job. It was designed by the late Myron Cottrell.

Here’s a little background: Myron was the guy who invented the “mini-ram” to replace Chevy’s convoluted long runner Tuned Port Injection intake manifold. A few years later, when Chevy (and Pontiac) came out with the LT1 for Corvettes, Camaros, and Firebirds, they had a manifold that looked very much like Cottrell’s mini-ram.

But even bigger news when dealing with the then-new 1993 Camaros and Firebirds was the length of the windshield cowl. It was humongous. And getting the engine out meant dropping it out from the bottom (after disconnecting brakes lines and peeling out a bunch of suspension components, not to mention the front cross member).

Cottrell knew hot rodders were more comfortable pulling an engine out from the top so he came up with what he called the “Happy Hooker.” It was a special lift plate designed to bolt to the engine so that it could come out topside. Cottrell set it up so that it would work on carbureted applications (Holley and Quadrajet applications).

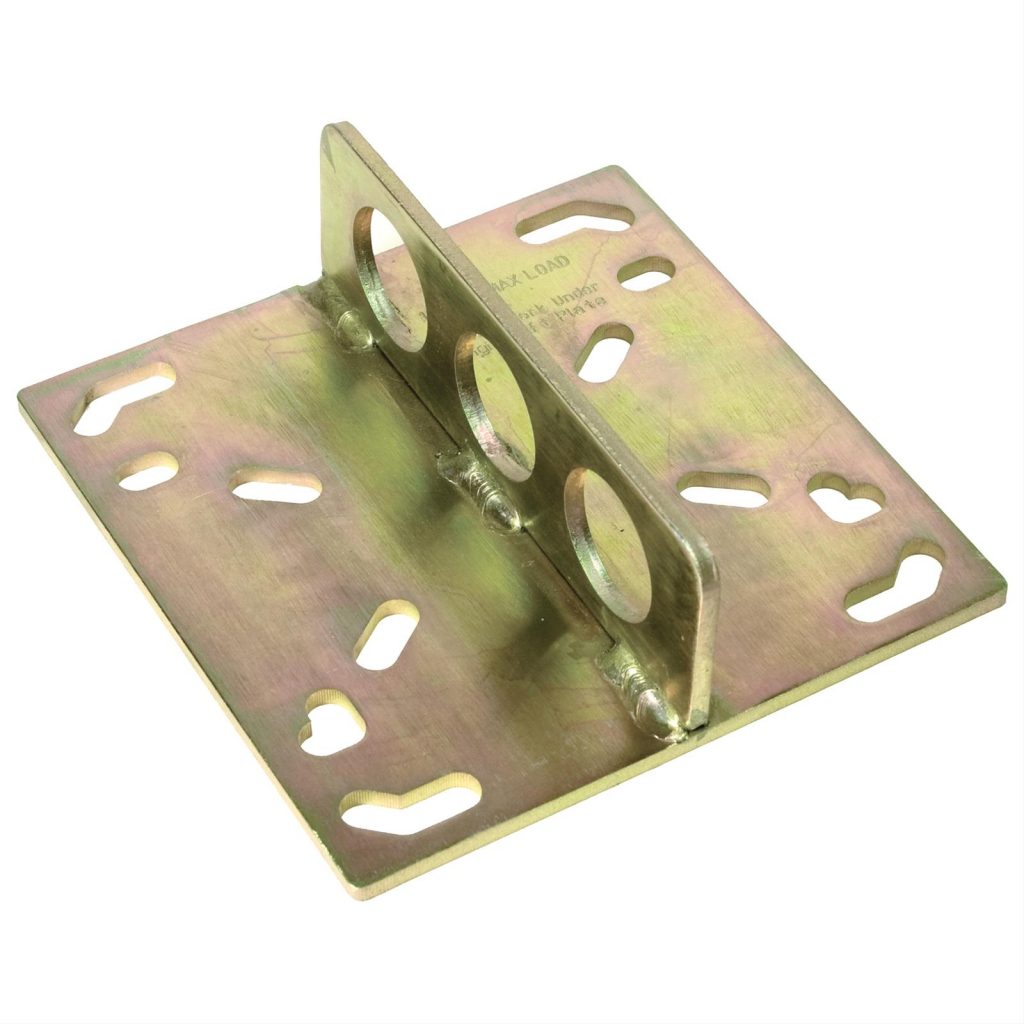

When it comes to lift plates, some enthusiasts really dig the examples that are designed to tilt. One of the coolest available is the pivot plate made by Mac’s Custom Tie-Downs and sold by Summit Racing.

Mac’s notes: “The Mac’s PiVOT is operated by turning the 1/2″ orientation bolt. This bolt is precision-machined to ensure smooth, easy operation with only 25 ft.-lbs. of torque required. This low operating torque gives you the option of using an impact wrench or simply adjusting the engine angle manually with a socket wrench.”

Essentially, it uses the center of gravity to provide control for the engine and transmission (or the engine alone) as you’re guiding it into place.

Cranking the adjustment bolt gently changes the angle. That control allows you to install the engine without fear of damaging a freshly detailed engine compartment or getting it snagged in wiring or plumbing. In terms of applications, the pivot tool is designed to work on several different bolt-pattern carbs including Rochester, Carter, Holley, Holley Dominator, and even Stromberg carbs. Summit Racing also stocks and sells adapters that adapt the tool to different EFI engine combinations. Bottom line: this is a handy, well-executed tool.

What if you have an engine with a heavily ported or sheet metal intake? Then you might consider an engine sling.

There are several different variations. Some are designed with chains that do the actual lifting while others use nylon straps.

Several of the chain jobs can be adjusted to change the angle of the engine as it’s set into place. For example, the K-Tool engine sling has a large hand crank on one end. It moves a bearing mounted drive screw which in turn, allows the engine to tilt. The K-Tool sling has a weight rating of 1,500 pounds.

NOTE: If you use a sling or another device with a drive screw for adjustment, be absolutely positive you lubricate the threads prior to use (it’s messy, but anti-seize is perfect for the job). You’ll thank us!

Most of the nylon strap style jobs are fixed in length but Summit Racing’s (part number SUM-905230) is manufactured with adjustable straps. Most of these slings attach with four points. This makes them very stable. In terms of strength, the strap design slings can support 1,200 pounds, so that means you can install an all iron big block with a transmission attached.

Summit Racing stocks and sells good old-fashioned lift chains too. They come equipped with a center hook and steel tabs that bolt to the engine.

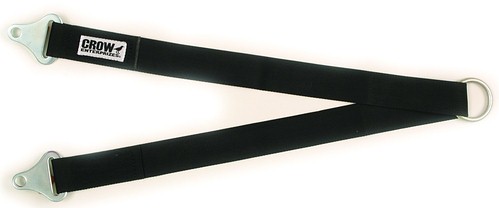

They’re simple to use and inexpensive (part number SUM-G1027 is available for under $20). Another option is a simple sprint car style sling. They’re fitted with 1.75-inch wide nylon strap with a centering ring. Each sling has a 500-lb. rating and many folks simply use two of them for engine installs. Each Crow Enterprizes sling at Summit Racing (part number 11645) sells for approximately $35.

As you can see, there’s more than one way to hook your engine to a cherry picker. “Getting Hooked” has never been easier and there’s something here for every budget. For more, check out the accompanying photos:

[…] Take your pick: Chain hoist or cherry picker. That’s the standard when it comes to yarding out (and replacing and simply moving) an engine in your ride or around your […] Read full article at http://www.onallcylinders.com […]

Great Informative article thank you for all that information

I’ll stick with a 3/8. With bolts It’s worked years for me!

Any time I pull an engine for replacement in my shop, I ALWAYS rob the OEM lift “eyes” before I return the core.

Personally, I don’t trust ANY threads tapped vertically in aluminum for removing/installing engines. I also avoid removing/installing engines with the intake manifold installed. My preferred method, especially with aluminum heads, is to bolt the lifting device into the exhaust manifold holes. That way, the threads aren’t stressed vertically. I use a 2 ton cherry picker and 3/4 ton (1500#) engine tilter and ONLY use grade 8, or, 10.9 (for metric) bolts when removing/installing engines.

I have used a birch tree limb and a manila rope, whatever works. I can tell you this, don’t use a cotton wood tree. The limbs are not real strong and it won’t hold a Cheby 6.

Interesting, and here I thought a lift plate was a lift plate. Never would of thought of using for specific vehicle applications.

Awesome i own a 2001 1500 ram 4×4 it threw the rods on the engine how much an where can i find a replacement engine im in miami gardens

I left a prior comment ref i need a replacement engine for a 2001 ram try?k 1500 v8