I am considering buying the basic Chevrolet 350 c.i.d. crate engine. I’ve heard lots of good things about it. I’d like to upgrade to a hydraulic roller cam at the same time. Rather than buy the more expensive roller cam Chevy crate engine, why can’t I just use that Chevrolet Performance hydraulic roller lifter kit — PN 12371042? It seems that adding the roller cam would be the least-expensive way to go. Thanks! — T.M.

…

Jeff Smith: This is a great question.

Unfortunately, the short answer is that this approach will not work.

We’ll go into much more detail so you know why and which engines would benefit from a conversion like this. The hydraulic roller cam conversion kit that you mentioned is intended to upgrade Chevy’s one-piece rear main seal small-block engines. A little history on the small-block Chevy is in order here.

The least-expensive and still popular small-block Chevy crate engine is a built-in-Mexico hold-over from the traditional two-piece rear main seal engine configuration that started in 1955 and ran until 1985. It is listed under PN NAL-12681429 at Summit Racing.

In 1986, GM upgraded the small-block in several ways. Among the changes was a one-piece rear main seal and, in passenger cars, these engines received hydraulic roller camshafts.

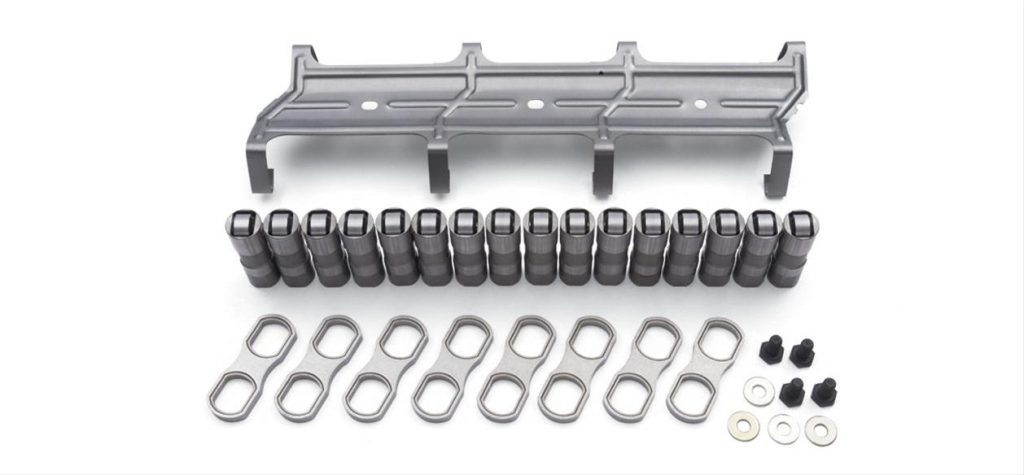

The block was modified to accept a hydraulic roller cam arrangement using what are called dog bones to retain the hydraulic roller lifters. One dog bone was used to retain a pair of hydraulic roller lifters to prevent the lifters from rotating which would destroy the camshaft. All eight dog bones were held in place by a large steel spring fixture retained in the lifter valley with three bolts using eight legs (also known as a spider) to hold the dog bones in place.

You didn’t mention which hydraulic roller crate engine you were interested in, but the least expensive small-block Chevy crate engine in the Chevrolet Performance catalog with a hydraulic roller camshaft is the SP350/357 long block (PN 19367080). This engine comes with a hydraulic roller camshaft with 215/223 degrees of duration at 0.050-inch tappet lift with 0.473/0.473-inch valve lift.

The problem is that the factory-style hydraulic roller camshaft will bolt into an older, two-piece rear main seal block but the block isn’t machined to accept the dog-bone style lifter retention configuration.

In order to use a roller camshaft in the older, two-piece rear main seal engines, you will need to use what are called retro-fit style hydraulic roller lifters that use a tie-bar between each pair of lifters. This tie-bar keeps the lifters aligned relative to the lobe. This is a very popular conversion for the older small-block Chevy but, unfortunately the retro-fit lifters are usually more expensive than the factory versions.

We did some investigating and found a set of Howard hydraulic roller lifters for a small-block Chevy (PN 91164N) that are priced very near the cost of the GM hydraulic roller lifter set. These are retro-fit tie-bar style hydraulic roller lifters that enjoy a good reputation for quality.

This would be the best approach for upgrading to a hydraulic roller cam in an older two-piece rear main seal small-block Chevy.

However, there will be other changes you will have to make.

The most important is that an aftermarket roller cam button will have to be used with any roller cam in an older two-piece rear main seal engine. This is necessary because thrust inside the engine tends to push a roller camshaft forward.

This does not occur with flat-tappet camshafts because each lobe on a flat tappet cam is ground to offset this forward thrust. This offset machining also induces the lifters to turn in the bore to improve wear.

A roller cam lobe, however, must be machined perpendicular to prevent damage to the lifters, so the forward thrust motion must be limited. If a cam button is not used, the cam will move forward and ignition timing will retard as engine speed increases.

We won’t go into all the details on how to create the proper clearance on a retro-fit roller cam as this information can be found in magazine articles and online. The easiest way we’ve found to limit the cam movement is to use the Cloyes aluminum timing cover (PN CLO-9-221).

The Cloyes cover has a built-in easy-to-access eccentric that will contact the cam button and can be quickly adjusted to 0.005-inch of endplay. This adds to the expense of the conversion, but adjusting the endplay is simple and easy. We mention this because we’ve spent an hour or more trying to set endplay with a cam button and spacers and epoxy-gluing shims to the back side of the stock timing cover. It’s a pain.

Another point worth mentioning is that hydraulic roller lifters are taller than traditional flat tappet lifters. This means the pushrod length will need to be reset using shorter pushrods.

Again, the process for establishing pushrod length has been covered in other places so we won’t get into that here. But you will need shorter pushrods.

One last point, the hydraulic roller cams intended for factory roller cam, one-piece rear main seal engines will use a stepped nose camshaft to fit behind the limiter plate bolted to the front of the block. Do not use these stepped nose cams in older, non-roller cam engines.

Yes, for you knowledgeable small-block fans, there is a way to use these step-nose cams in a two-piece rear mains seal engine but we won’t go into that as it has a very limited appeal — so please don’t send us emails telling us it can be done — we already know.

Stepped nose roller cams also use a different cam gear bolt pattern. The traditional timing set and cam for older small-blocks will work for a roller as long as a cam button is included and properly adjusted.

This was a longer answer than what you were probably anticipating but we thought the question was good and deserved an expanded answer. As it turns out, your idea is really pretty solid and since the Howard lifters are about the same price as the GM lifter kit, the conversion won’t be that expensive.

[…] I am considering buying the basic Chevrolet 350 c.i.d. crate engine. I’ve heard lots of good things about it. I’d like to upgrade to a hydraulic roller cam at the […] Read full article at http://www.onallcylinders.com […]

I had my 350 Chevy 1976 upgraded to a roller cam and now I’m hearing a small knocking noise on one side of the engine. Does this usually mean that periodically you have to adjust? I’m gonna say the rockers I’m not sure get rid of the noise.

What roller camshaft do you recommend?

I have the GM crate SP350/357 engine and it is NOT a hydraulic roller cam, but a hydraulic FLAT tappet cam.

Gotta love that expanded short answer about everything that can possibly go wrong. Seems like nothing is quite as easy now as it once was before it became aware of the possibility of the usual problems that are considered to be at an acceptable level even before reading the comprehensive instructions that had a notice about the surprising degrees of difficulty that immediately popped up a red flag that went, for the most part, totally unnoticed due to the origins of the printed instructions from China being obviously misleading because the table of contents along with all manner of forewarnings being PRINTED IN BLACK AND WHITE causing the RED FLAG to be useless despite the initial shock that immediately follows every red flag that pops up suddenly and disturbs the curious readers state of euphoria that all people of the Earth work so hard to achieve at least once a day. The incident is now known as a covert quest for lucid lifters and what makes them tick in a hydraulic state of love for the SBC. Talk about a bummer man, and now all this lunacy about the lunar dark side is the galactic grow house for shrooms (allegedly), which puts me in the mind of Johnny Cash singing his smash hit about “Stare At The Man In The Moon ‘Till Nancy Reagan Pops Like A Weasel”. It’s a pleasant tune but the subliminal message about JUST SAY NO reminds me that I just read another article about the holy grail SBC that landed me securely in a straight jacket. It was the jacket or climbing a clock tower with my sidekick and 5000 rounds of full metal jacket bliss. Lithium haze all in my brain ……

I thought the answer was well written and complete. It gave the readers a thorough idea of what is involved and clearly explained why s*** sometimes happens. As far as Mr. Wilson’s comments go. He needs to stop smoking before he writes what he is thinking.

Jeff on your article (Roller upgrade for small block 350) posted 8/27/20, you answered T.M’s question by saying that the least expensive small block Chevy is a built in Mexico hold-over.

What’s wrong with being built in Mexico?

You said it like it’s a bad thing.

I was built in Mexico and can probably kick your @#$.

I read the same article and came away with a different take.

If you order a crate engine from Mexico, you may be interested in knowing it will have an older style, 2 piece seal.

Information is always “positive”, so each can make a selection that best fits their need.

As for being physically fit, there’s always some bigger and better trained.

I read the same article and came away with a different take.

If you order a crate engine from Mexico, you may be interested in knowing it will have an older style, 2 piece seal.

Information is always “positive”, so each can make a selection that best fits their need.

As for being physically fit, there’s always someone bigger, and better trained.

Thank you so very much for this info. I have a tired (245k) 90 G20 350. I wanted to rebuild with roller parts. Now I know to find a factory roller motor to replace it.

VERY WELL EXPLAINED!!!! Just the facts. Keep this kind of info coming. Thank you, Nick

Great response with very clear facts and info, I found myself asking a lot of the same questions about push rod length and a desire to run solid lifters on hydraulic roller camshaft after watching an episode of Engine Masters. I’ve seen a lot of conflicting info out there; which just adds to the confusion and leads to more questions.

Great feedback and greatly appreciate the links and details.