Q:

What is the purpose of a PCV valve?

A:

The PCV valve is an important part of your crankshaft ventilation system. It serves a few primary function related to regulating positive crankcase ventilation.

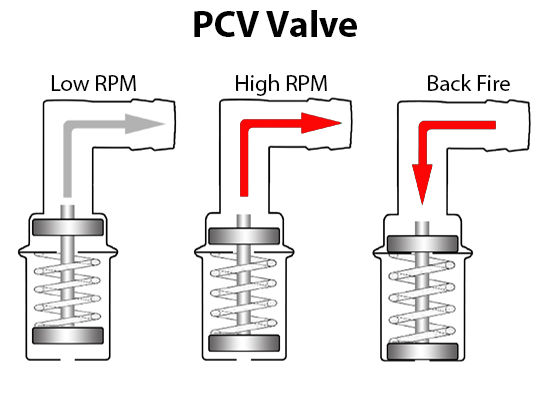

Your vehicle’s PCV valve works by stopping excessive amounts of oil from being drawn out of the crankcase and regulating the amount of vacuum applied to the crankcase. At low rpm, when vacuum is high, the valve closes slightly to reduce airflow. At higher rpm, when vacuum is reduced, the valve opens more to increase airflow.

The valve also acts as a one-way check valve to prevent forced induction or a backfire. In other words, it won’t allow the crankcase to be pressurized.

Here’s a useful diagram of a PCV valve working at low rpm, high rpm, and during a backfire event:

Now you know what a PCV valve does, but you might be wondering how it affects vehicle performance. The valve controls the PCV system, which—when properly maintained—can help the engine generate a little more power.

The slight vacuum in the crankcase improves the seal of the piston rings and valve stems, which keeps the compression in the chamber at the desired level. A PCV system also reduces windage and oil aeration, which can cause drag on the rotating assembly and rob your ride of some of its power.

Follow your maintenance schedule and make sure the PCV valve and hoses stay clean and clear to extend the life of your oil and engine.

I can remember the days when the engines had “Breather” tubes/pipes to relieve crankcase pressure. The problem with that was if you let the Engine sit in one spot…. It left a puddle of oil behind.(except Mercedes Engines,they had their breather tube on top of the Cam/Valve cover with a hose & pipe that exhausted above the Carburetor inlet so the vapor or oil drips would burn through the engine)(V.W.too) That’s what we were told back in the 60’s that the P.C.V. was to cutdown on pollution. In the late 50’s the Y-Block V8 Fords had a P.C.V. Valve that you could take a part and clean it, not like the plastic CRAP they have today, replace it….Sad!

Great infographic, easy to read!

The calibration on those “cheap plastic” valves are dedicated to engine families and far exceed those one size fits all “take apart” valves of the bygone days.

Having a proper PCV system is important for a number of different reasons. A slight vacuum in the sealed crankcase promotes better ring sealing which helps increase power. Blow-by vapors from the combustion process that contaminate the oil, cause sludge build up and shorten the useful life of oil are reduced. The harmful unburned hydrocarbons found in the vapors are routed back into the intake tract for more complete burning instead of being released into the atmosphere that we breathe.

The specific requirements of each engine is different but the design of most common PCV valves is a compromise so they can work with several different engines. But now there’s an adjustable PCV valve available from M.E.Wagner. It’s their Dual Flow Billet Aluminum adjustable valve

P.N. DF-17. It features separate adjustments and port nipples for low and high engine rpm tuning. It should work well for engine builds with radical cam profiles that typically have very little intake manifold vacuum available to operate conventional PCV valves.