I have a 4.030 small block Chevy with 1/16 inch rings. I have a 4.125 inch bore ring set that I’ll never use. Can I use the larger rings and just cut them down to create the proper end gap? How far can I go? I know at some point the ring just won’t be right, but what is the limit?

E.G.

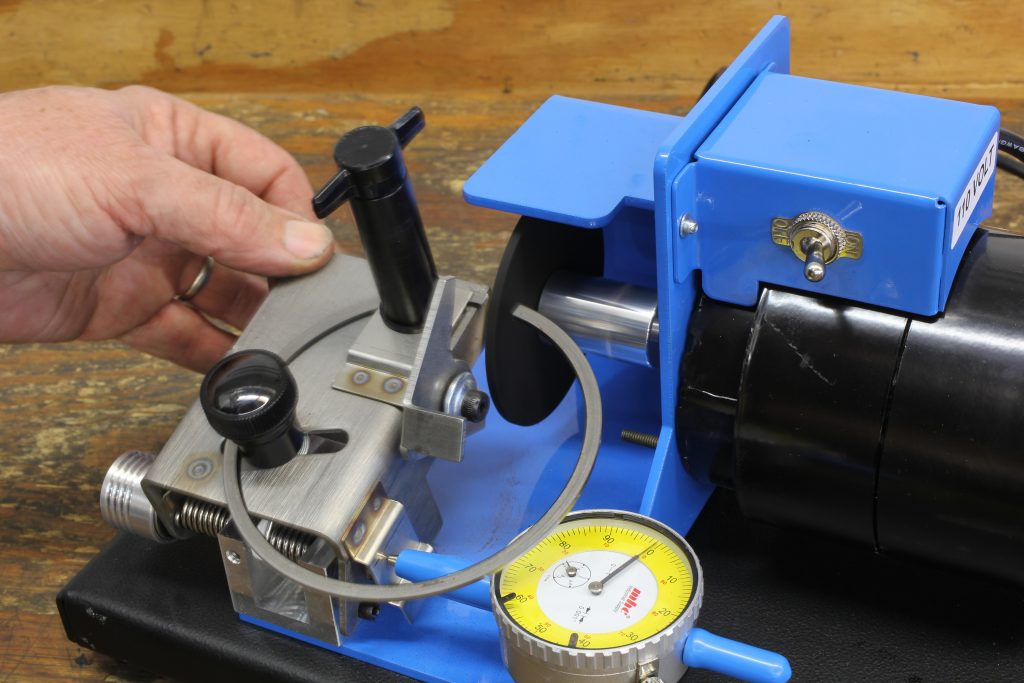

Jeff Smith: This is an interesting question. We posed this to our friend Lake Speed, Jr. at Total Seal. He told us that it’s Total Seal’s policy not to exceed 0.010 inch of ring oversize to custom-set end gaps. This is why oversize rings generally are 0.005 inch larger than the bore size. For a 4.030 inch bore, the oversize ring would be 4.035 inch. Speed said that cutting down larger diameters will oval the ring, which will create a giant leak path that will kill cylinder pressure. Why take the risk?

Looking at this from a larger perspective, a basic set of 1/16 inch piston rings are now very affordable considering the critical nature of their job. For example, Summit Racing sells a non-file fit ring package with a 1/16-top, 1/16- second, and 3/16-inch oil ring for far less than $100. A file-fit ring set will start at around $120. That makes a set of file-fit iron rings for a basic 0.030-over, 4.00 inch bore small block Chevy is a smart investment.

Investing a little more money into a set of ductile iron rings with a moly coating that will not only seal better but last longer is not a bad idea. For one thing, as ring seal improves, the oil will last longer because blow-by, which carries all kinds of nasty combustion chemicals into the oil, is reduced.

But rings are really only part of the issue. You didn’t mention if you’ve invested in proper torque plate honing of the cylinder. Torque plates bolted to the block simulate the stress inducted into the block when the heads are bolted in place. This is an absolute must if you are even mildly concerned with improving ring seal.

Most enthusiasts are perhaps most concerned about ring end gap as a leak path. If you improve the bore roundness with a torque plate, you’ve at least attempted to improve the seal between the ring and the bore. But there are two other leak paths: between the ring and cylinder wall and between the ring and the piston groove.

You don’t mention if these pistons are new. Let’s assume for a second that these are used. Pistons with a lot of time on them will tend to wear the ring lands, which will increase their width. This creates more space for combustion gasses to escape around the ring, which reduces sealing efficiency. This is worth looking at when it’s time for a new set of pistons. Some piston companies are now applying a ring land hardening process for the top ring in order to improve its wear characteristics and reduce blowby.

These are just a few things to consider when thinking about a new set of rings. They may be a key to unlocking hidden horsepower.

I’m building a 350 with a stroke kit. It’s bored .030 I’m finding a recommendation of a end gap for the top ring @ .016 and should I make the second ring @ .020. Are these both good ? Please advise and thank you.

Kim

You should always go with the recommended clearance for top ring end gap from the manufacturer. For example, the ring end gap for a KB hypereutectic piston is much greater than one for a forged or cast aluminum piston. This is because KB moves its ring land up closer to the top of the piston, which exposes the ring to higher temperatures. So using a typical forged piston recommendation of 0.0045-inch per inch of bore would give you 0.018-inch rop end ring gap. But a KB piston uses a spec 0.0065-inch – which for a 4.030-inch bore would be 0.0026-inch – a massive difference. So its critical to know which piston you are using and use that company’s spec for their piston. If you used the tigher spec on a KB hyereutectic piston, the ring will butt together, then stick and then literaly bind in the bore and break the top of the piston off inside the cylinder! We’ve seen it happen! Tread carefully here.

I took the heads off my 1994 Jeep to have them reworked And I cleaned the piston tops off and it had 50 on top of it I’m assuming that’s 50 over I never heard of such a thing where do you get 50 over pistols let alone 50 over rering kits? Why would anyone do such a thing to a 4.0 jeep engine?