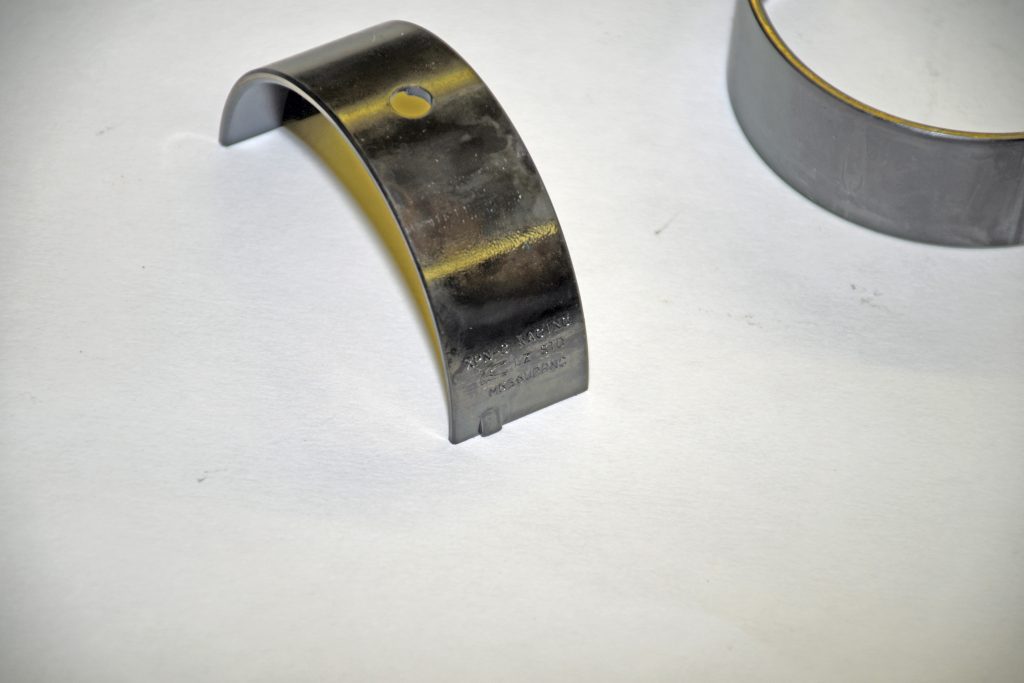

It should be no secret to anyone reading this that bearings are used for the camshaft along with the crankshaft main and rod journals in an automotive application. While some race applications make use of a roller bearing for the camshaft (an expensive and somewhat complicated arrangement) the most common high performance bearings are bi-metal or tri-metal insert jobs. The main bearings and rod bearings are two-piece affairs while the cam bearings are typically one-piece in design.

In operation, oil is pumped between the bearing surface and a spinning crank or cam journal. As a result, the top of the bearing insert is typically smooth and flat. Bearings are designed with a rigid metal or aluminum backing. This provides the foundation for the bearing, and maintains the shape and press-fit of the insert under sometimes severe conditions. With a tri-metal bearing, a layer of heat-conductive copper is plated onto the metal backing. Next comes a nickel barrier followed by a soft overlay. In the case of a bi-metal bearing, the backing has an aluminum bonding layer applied followed by a soft bearing overlay.

According to King Engine Bearings, “the second layer in a bi-metal bearing is the lining. It is relatively thick. The thickness is about 0.012″. Large thickness of the lining is a very important feature of bi-metal bearings. It allows for greater misalignments and other geometry irregularities. It also provides good embeddability for both large and small foreign particles.

“Commonly the lining is made of an aluminum alloy containing 6 to 20% tin. Tin serves as a solid lubricant and provides anti-friction properties (compatibility, conformability, embeddability).

“Another additive is 2 to 4% of silicon dispersed in the aluminum in the form of fine particles. Hard silicon strengthens the alloy and also serves as an abrasive, polishing the journal surface. Presence of silicon is particularly important for engines with cast iron crankshafts.

“The alloy may be additionally strengthened by copper, nickel and other elements.

“The two main layers (steel and lining) are bonded to each other by means of a bonding layer of pure aluminum.”

King Bearings notes the properties and advantages of a bi-metal bearing:

- Good fatigue strength due to the both fine micro-structure and hardening effect of silicon and copper

- Very good seizure resistance particularly with cast iron crankshafts. This is due to silicon particles. They continuously polish the crankshaft surface and prevent seizure

- Good embeddability. The lining is thick so it is capable of absorbing both small and large dirt particles circulating with oil

- Good conformability. In contrast to tri-metal bearings with thin overlays, bi-metal materials can accommodate greater misalignments

- Good wear resistance due to the relatively hard aluminum alloy, which is harder than the soft overlays of tri-metal bearings.

Fair enough, but what about tri-metal bearing details? Here’s the inside story from the folks at King Bearings:

“In addition to the supporting steel back, the structure has an intermediate layer made up of a copper alloy containing 20 to 25% lead as a solid lubricant and 2 to 5% tin as a strengthening additive.

“The third layer is the lead based overlay (or Babbitt) applied over the intermediate layer. The lead based alloy contains about 10% tin, enhancing its corrosion resistance and a few percent copper that increases the overlay strength. Thickness of the overlay is only 0.0005″ to 0.0008″. The low overlay thickness of tri-metal bearings limits their anti-friction properties like seizure resistance, conformability and embeddability. When the thin overlay is removed (even partially) the anti-friction properties drop dramatically. Why not increase the overlay thickness? Unfortunately, the load capacity of a soft overlay is strongly dependent upon its thickness. The thinner the overlay, the greater its load capacity. The overlay thickness is a compromise between the strength and the anti-friction properties.

“Between the intermediate layer and the overlay there is a thin nickel layer. Nickel serves as a barrier preventing a diffusion of tin from the overlay into the intermediate layer. Thickness of the nickel barrier is 0.000040″ to 0.000080″.”

Here are the properties and advantages of a tri-metal bearing (from the folks at King Engine Bearings):

- Very good fatigue strength due to the both strong intermediate layer and hardening effect of copper in the relatively thin overlay

- Excellent seizure resistance provided by the lead based overlay. Seizure resistance drops sharply when the overlay is removed in direct metal-to-metal contact

- Excellent embeddability of small dirt particles

- Excellent conformability for small misalignments

“A tri-metal material operates very well as long as the overlay exists. However, the overlay is thin and may be easily removed from the surface. Even partial exposure of the intermediate layer will cause dramatic lowering of the bearing properties.

“As a result, tri-metal bearings are more sensitive to misalignments and distortions than bi-metal bearings.”

King Bearing has different types of bearings for different applications. Summit Racing offers all sorts of them. So what are the big differences?

First let’s look at the King bi-metal bearings and the respective series (the series is listed in the Summit Racing online catalog and also found in the part number):

- AM is the softest bi-metal material. It contains 20% tin, 1% copper and no silicon. AM bearings are used in passenger cars with low and medium load gasoline engines.

- SI is silicon containing material for medium load gasoline engines, particularly engines using nodular cast iron crankshafts.

- HP, which has material containing silicon content for medium load high performance engines with nodular cast iron cranks and also for high load short duration engines.

Next, let’s look at the tri-metal bearings from King Engine Bearings:

- CP is the softest tri-metal material for passenger cars with medium load gasoline engines.

- SX bearings have higher load capacity due to the stronger intermediate alloy and harder and thinner Babbitt overlay. The overlay of SX contains 5% copper instead of the 3% content in the CP series and its thickness is decreased from 0.0007″ to 0.0005″. Applications of SX bearings are passenger cars with medium-to-high load engines.

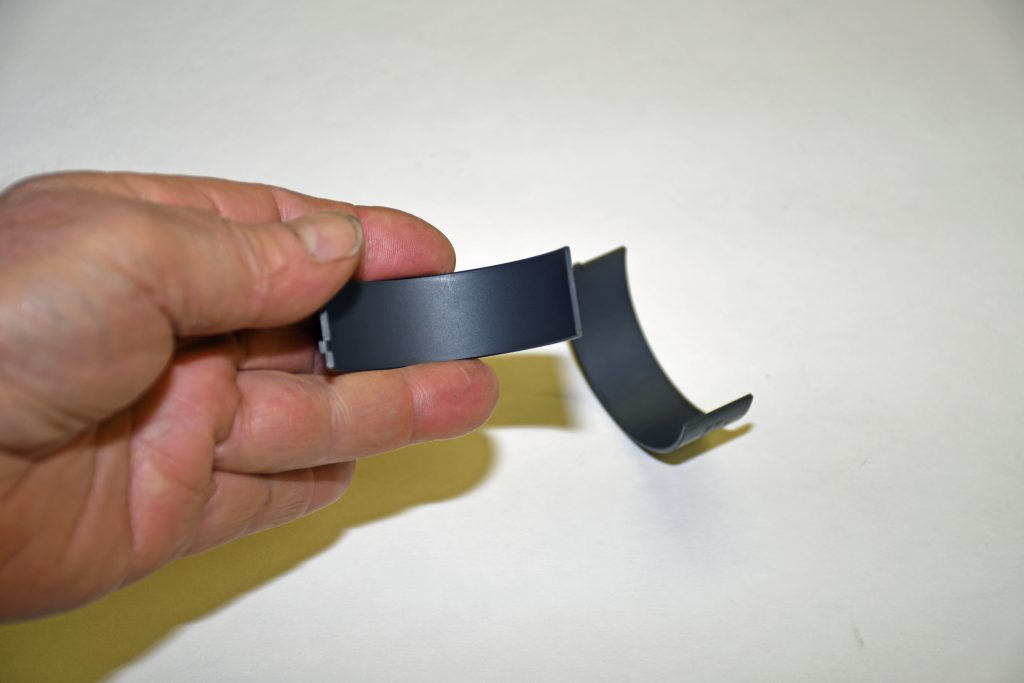

- XP bearings were developed for high load high performance engines. XP bearings are easily recognizable due to their distinctive deep dark color that comes from King’s proprietary surface hardening treatment. The hardened surface provide a significant increase (about 17%) of load carrying capacity when compared to a conventional bearing.

Some bearings (King and others) are available with a polymer coating. Typically, these coatings are based upon a polymer along with additives in the form of small particles of solid lubricants (for example, molybdenum disulfide, graphite, PTFE). Polymer coatings applied onto a conventional high performance tri-metal bearing is quite popular.

The main purpose of these coatings applications is to provide extra protection from wear that can be caused by an absence of oil film. A good example is a cold start. Basically, coatings prolong bearing life when operating with a very thin or negligible oil film.

According to King Engine Bearings, their proprietary “pMaxKote is a factory applied nano-composite polymer coating. It improves wear resistance and protects bearings during periods of marginal lubrication. pMaxKote contains ceramic nano-composite particles and solid lubricant. It functions as a fourth layer over the pMaxBlack tri-metal bearing structure without changing the original wall thickness dimensions.”

FYI the coated King bearings do not add to the overall thickness in the bearing. In the King Engine Bearings lineup sold by Summit Racing, pMaxKote bearings can be identified by the “C” found in the part number. They’re also shown as “coated bearings” in the Summit Racing catalog.

***

As you can see, there’s more to engine bearings than first meets the eye. In the following photos, we’ll dig into the bearings and give you a better look at some of the additional features. Some are actually rather surprising. Check them out:

[…] It should be no secret to anyone reading this that bearings are used for the camshaft along with the crankshaft main and rod journals in an automotive application. While some […] Read full article at http://www.onallcylinders.com […]

My roller on my lifter seized and scratched up the cam and roller ended up with a flat spot. Couldn’t find any ferrous metal in the oil filter, just non magnetic silver metal which looks like aluminium. I presume this is off my cam bearings. Engine is a Chev 6.5 diesel. I have stuck a new lifter in. Do you think it would be okay to drive 1200 kilometres if no more metal turns up in oil filter.??