The mechanical fuel pump pushrod is a pretty simple device. It joins a lobe on the camshaft (or an eccentric) to a lever on the fuel pump. As the engine (and consequently, the cam) rotates, the pushrod moves the fuel pump lever up and down, drawing fuel from the tank and relaying it to the carburetor(s).

Simple stuff. But as engine speed goes up, the fuel pump pushrod can float—just like a valve spring.

The fix here is to reduce the weight of the pushrod. Fair enough, but a potentially larger issue is when you add a steel cam, such as many roller examples, into the equation. Here, there’s a mismatch of materials. And that’s not good because it can cause premature wear on the rod or, worse yet, the cam.

Back when mechanical fuel pumps were the norm, engines pretty much all had cast cams. The steel pushrod would never wear, and the cam was happy too. But today’s steel cams cause all sorts of grief. A fuel pump pushrod can easily wear quickly or the end can mushroom. If it mushrooms, you might have a devil of time getting it out of the cylinder block. The fix here is to use a pushrod that is compatible with the camshaft.

Selecting a Fuel Pump Pushrod for a High Performance Engine

Prior to the move to electronic fuel injection, NASCAR cup car engines typically made use of mechanical fuel pumps. What plagues modified street or street/strip engines also plagued those NASCAR engines (keeping in mind some of those engines operated in the 8,000 to 10,000 RPM range and raced for 500 miles). Those cup car engines also made use of steel camshafts—some of which had case-hardened lobes.

While the mechanical pumps have been replaced today due to the conversion to EFI, mechanical fuel pump technology (along with mechanical fuel pump pushrod technology) has remained.

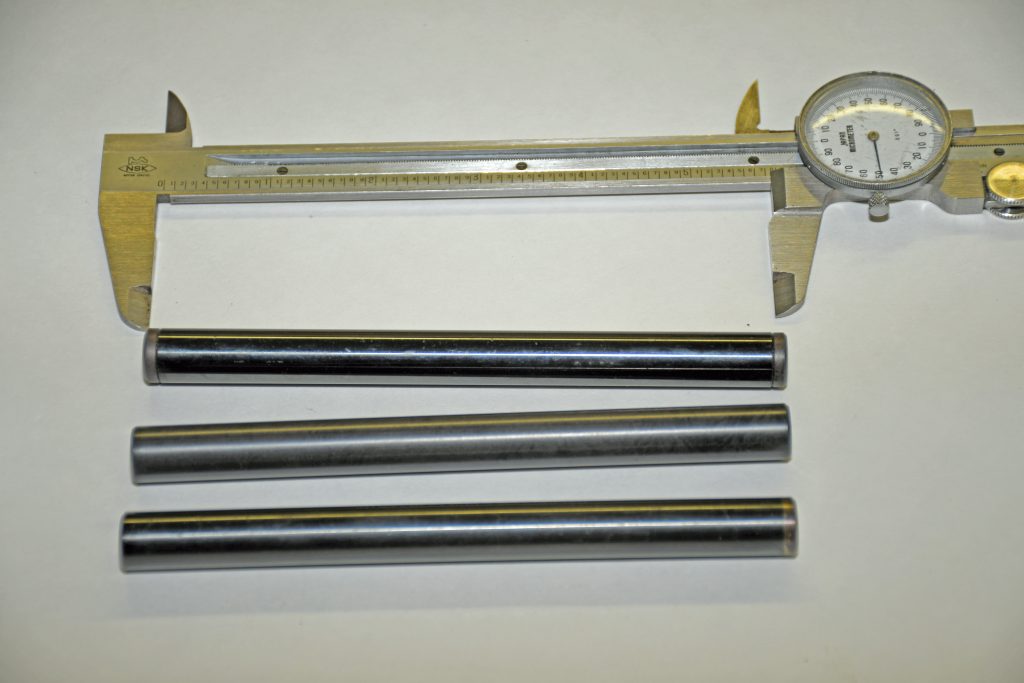

So what’s available? Summit Racing offers all sorts of solutions. Three examples from the Summit Racing catalog (for common Chevy engines) include a lightweight pushrod from Moroso, a steel pushrod with a bronze tip from Crane Cams, along with a composite pushrod from Howard’s Cams.

Moroso’s #65750 fuel pump pushrod is a lightweight design with hardened ends. The lightweight (approximately 64 grams on the writer’s postage scale) is likely half the weight of a stock Chevy pushrod. It’s designed to reduce pump float and, as a consequence, fuel starvation. While not advertised or sold for use with steel camshaft cores, some folks have had success with them.

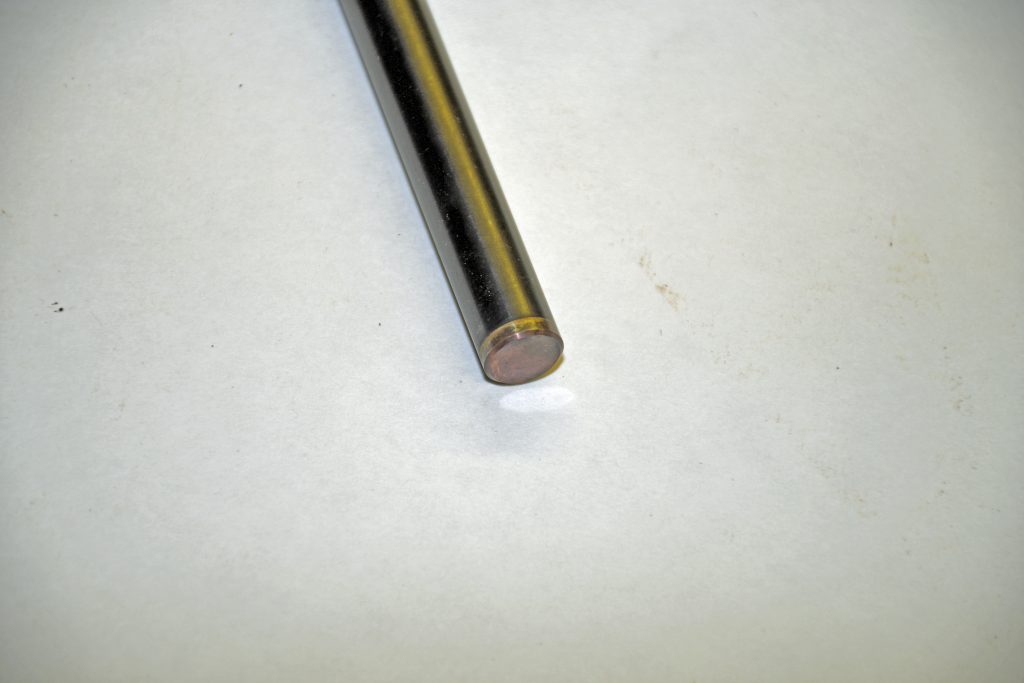

The Crane Cams #11985-1 pushrod is heat treated and it incorporates a bronze tip (which is installed on the camshaft side). Crane Cams notes that it is specifically intended for use on 8620- and 9310-alloy steel camshafts along with hard-faced cams. It too is very light. On our scale, it came in at 62 grams.

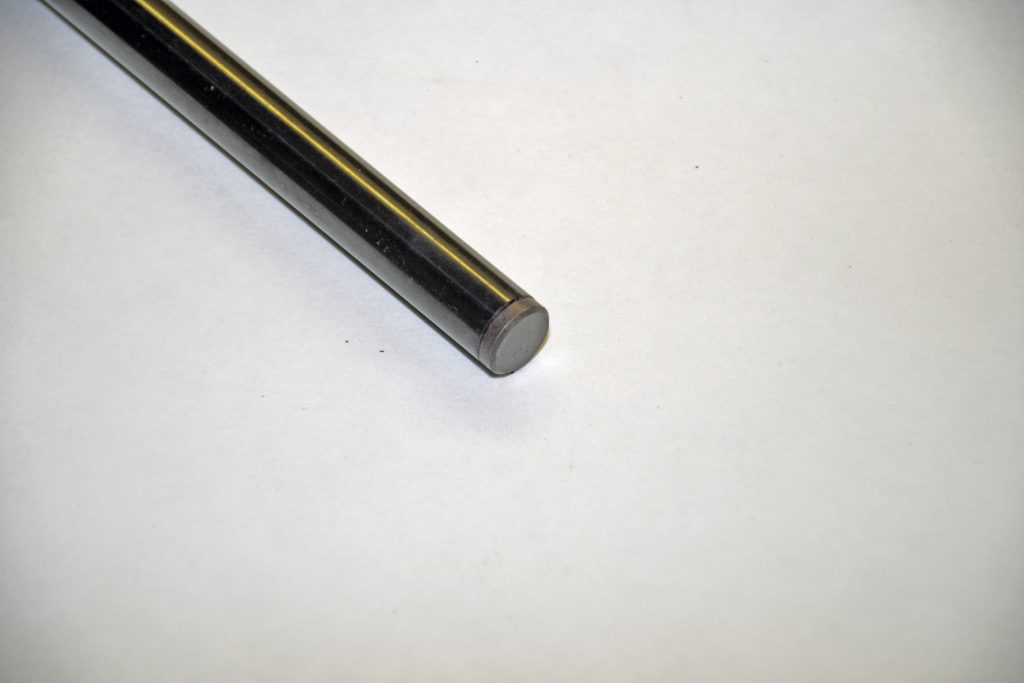

The Howard’s Cams #94475 pushrod is manufactured from a proprietary polymer mix. Howard’s Cams notes that the bearing-grade polymer is reinforced with carbon. The polymer is very gentle on the cam lobe and it’s possible to use it on either cast or steel billet camshafts. Since it’s bearing grade, it is self-lubricating. These pushrods are extremely light—Howard’s advertises them as 0.9 ounce (25.5 grams), but on our postage scale it came in under 20 grams.

All three of the above pushrods measure 0.500-inch in diameter. The Crane Cams rod measured in at 5.758 inches long; the Howard’s Cams example measured 5.750 inches and the Moroso was marginally longer at 5.759-inches overall.

Installing a High Performance Mechanical Fuel Pump Pushrod

In terms of installation, they all go in the same way as a stock pushrod (keeping in mind the Crane Cams rod’s bronze tip must be installed with the tip facing the camshaft). Obviously, the bigger the pump capacity (and stronger the pump spring pressure), the bigger the risk of mushrooming a pushrod.

For a closer look at mechanical fuel pump pushrod options, check out the pics below:

Again a Chevrolet question(problem) I really wish you would reach a little more Out of the Box? There is more than Chevys out there!

Hello Tystyx, thanks for reading. And we’ve been publishing a lot of stuff for other makes lately, like our Mopar Hemi Spec Guides and some Ford engine tests from Richard Holdener.

…

Heck, we’re even writing stuff for Electric Vehicles too, if you’re into EVs.

…

Check back daily, as we’re posting new articles all the time.

You never spoke about roller tip fuel pump push rods like Comp-Cams part number 4609. Also it should be noted example bronze fuel pump push rods will mushroom over time and can be very difficult to remove from the block.

IVE READ COMP CAMS BRONZE TIP CAN BREAK OFF ( NOT SURE IF TRUE) BUT MY COMP CAM BRONZE TIP EITHER WORE OUT IN 3000 MILES OR BROKE OFF , WAITING FOR BORESCOPE TO LOOK IN OIL PAN . BUT ALSO STATED, BETTER THE ROD TIP WEAR OR BREAK OFF THAN WIPE OUT THE CAM LOBE .

HOW DID YOU REMOVE THE BROKEN BRONZE TIP? DID YOU NEED TO REMOVE THE OIL PAN ? OR….?

Believe it or not, everyone doesn’t run a Chevrolet engine. I choose the Ford 351 Cleveland for its ability to make considerably higher power levels thanks to its high flowing canted valve cylinder heads. The mechanical fuel pump doesn’t use a pushrod. It has a lever arm that rides on an eccentric that is attached on the front of the camshaft drive sprocket. The eccentric is a two piece design which allows the outer piece that contacts the fuel pump lever to rotate freely which reduces friction at the point of contact with the pump arm. The aftermarket offers a two piece eccentric that uses needle bearings between the two pieces which greatly reduces friction as the outer piece rotates around the inner piece.

Do all fuel pumps require a rod or is there any that relies on cam pushing on it

If I understand your question, the answer is going to be dependent on the specific engine. As an example, I’m almost certain that the AMC 258 I6’s mechanical fuel pump lever rides directly on the cam and does not require a pushrod.

Having trouble with Pushrod stuck in the bore sleeve on 1976 GMC G1500 Vandura LWB 350 5.7L , founded out when replacing the Mechanical fuel pump. How does the stuck Pushrod can be removed to install a new one ? Or if other option is to bypass the problem by installing an Electric Fuel Pump. And which is the best replacement because the original pump has 2 lines that go in; gas line and oil line and one out to the 4 barrel Carburetor. The Electric Gas Pumps I’ve seen only have 1 input and 1 out put. What happens to the oil line, does it gets plugged ?

I wanna know if anyone just left the broken bronze piece in the pan & hoped the soft piece came out in next oil change or got eattin by gears .OR did you need to pull the pan to remove OR were you able to flush that little piece out somehow?? Lets HEAR these answers please POST EM , DONT email me please