Matthew Bochnak runs the How-To Motorcycle Repair website and has his own MatthewMCRepair channel on YouTube. If something is ailing your bike, chances are Matt has a post that will help you fix it.

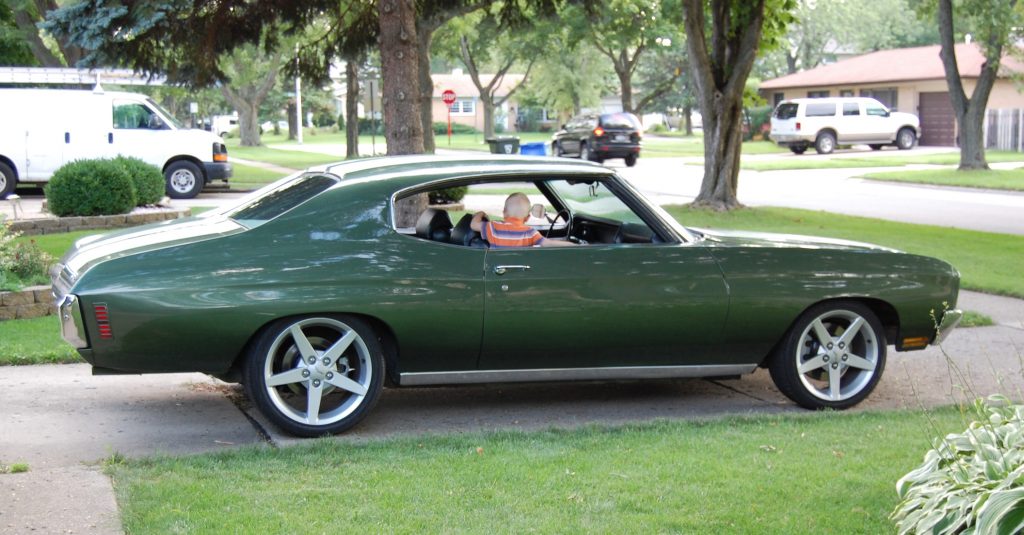

But Matt doesn’t tie himself down to two wheels. In fact, he’s got a pretty hot 1970 Chevy Chevelle that’s about to get a whole lot hotter.

He’s already replaced the Chevelle’s four-wheel manual drums with C5 Corvette disc brakes, rebuilt the front suspension and added tubular upper control arms, and converted to a quick-ratio power steering box. Under the hood was a small block 350 with a Holley four-barrel carburetor, headers, and other minor upgrades.

A New Motor for the Classic Musclecar

We said “was” back there because that small block Chevy motor just got yanked in favor of a freshly-built turbocharged LS engine.

Being a mechanical engineer by trade, Matt did a lot of research and came to the conclusion that a 5.3L iron block LS with a stock bottom end and stock cylinder heads would be able to handle around 500 horsepower at 14 PSI of boost running either gasoline or E85.

Whether it’s on two wheels or four, everybody loves horsepower. To that end, Matt has documented the build from teardown to turbo plumbing—in fact he’s got 37, no wait, 38 episodes now (and counting) as we write this.

Matt’s nothing if not thorough.

The 5.3L Turbo LS Engine Build

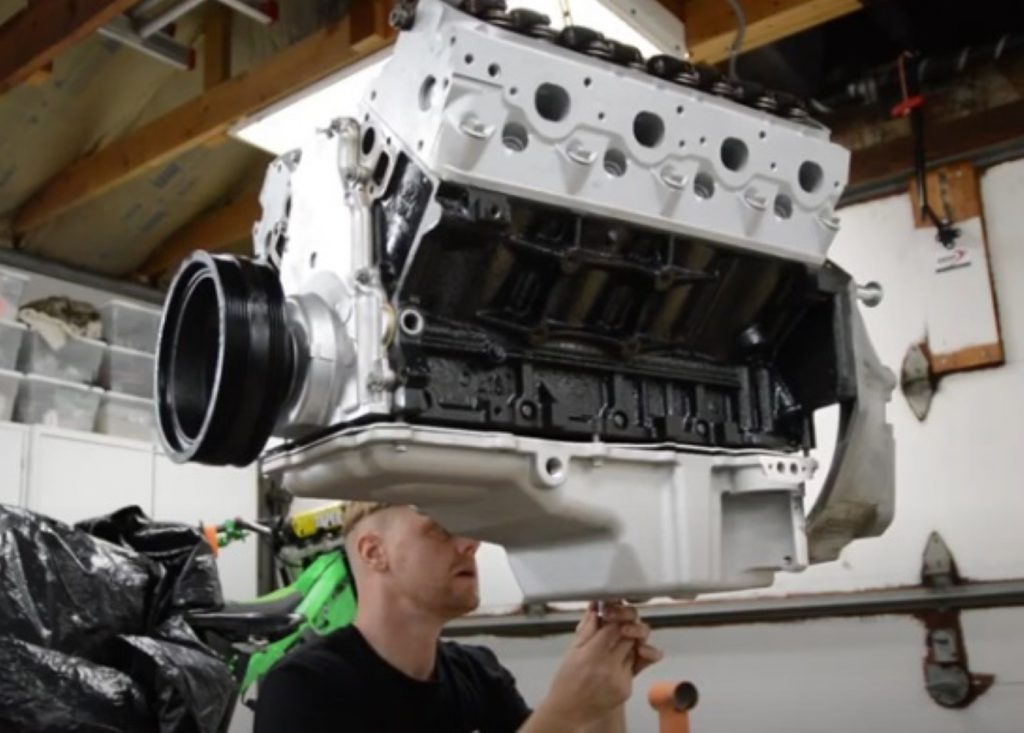

The 5.3L came out of a 2005 GM truck with about 140,000 miles on the clock. Matt tore it down to the bare block and evaluated the condition of the parts. The block was in great shape; in fact, the cylinders still had the factory crosshatch and just needed a ball hone to clean them up.

Matt sent the crankshaft out to have the journals polished, and he cleaned the rods and pistons using a home-built vapor blast cabinet. Also known as wet blasting, vapor blasting mixes water and abrasive media (usually fine glass bead or soda) under pressure to remove grease, rust, factory coatings, and other contaminants from parts. The process is quicker than traditional dry blasting and much gentler on metal, leaving a very smooth finish.

Before disassembling the engine, Matt did a leakdown test. He found 20 to 75 percent leakage in all cylinders thanks to badly pitted exhaust valves and seats. He vapor-blasted and lapped the valves, then sent the heads to the machine shop to be decked and get a three-angle valve job. The shop assembled the heads with new PAC Racing valve springs, retainers, and seals.

With the parts cleaned, machined, and rebuilt, Matt put the long block together. He installed new cam bearings and replaced the factory camshaft with a hydraulic roller cam rated at 223°/230° duration @ .050 and .585 inches of lift.

(If you’re playing along at home, Summit Racing’s got a Trick Flow Track Max® cam that is comparable at 228°/230° duration @.050 and the same .585 inches of lift.)

Matt then installed new main and rod bearings and assembled the bottom end. He used a set of Summit Racing piston rings gapped to .027 inch as recommended for forced induction applications. He also installed a new Cloyes timing set and a Melling oil pump.

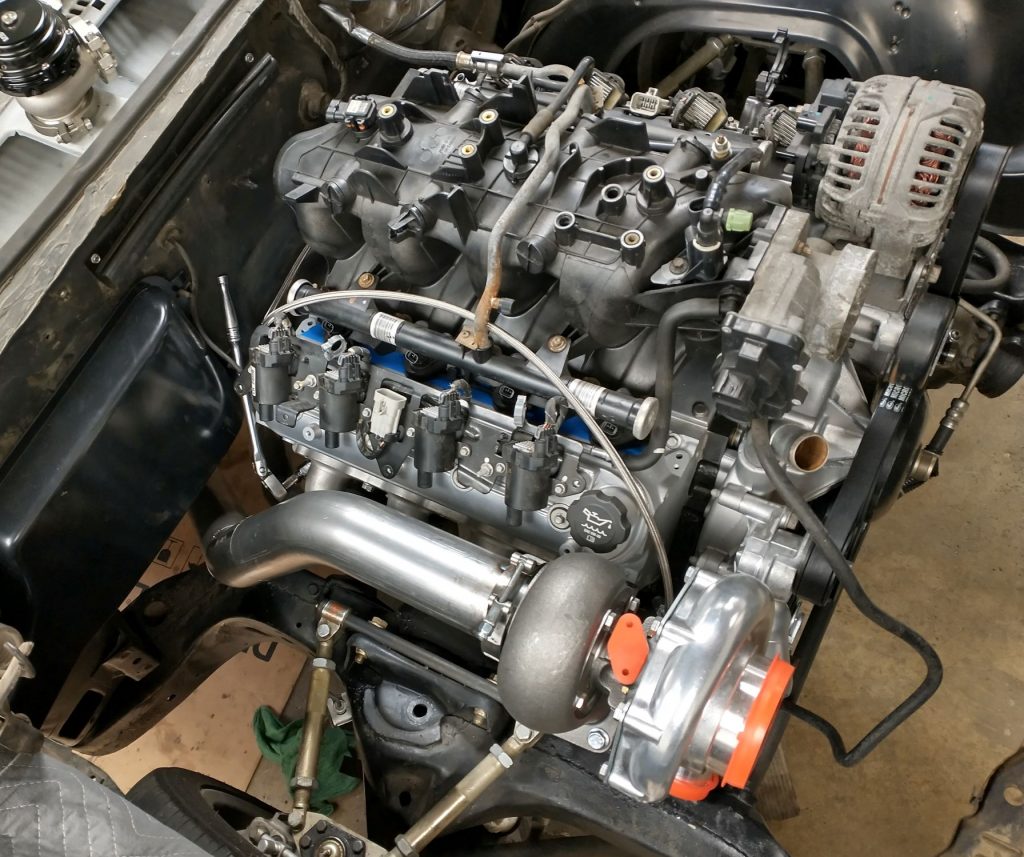

The rebuilt cylinder heads were bolted to the block using new bolts and Chevrolet Performance MLS head gaskets. Matt reused the factory rocker arms and dropped in new LS7-style lifters. Even though the heads were decked, he lucked out and was able to use stock-length pushrods. Fast-forward a bit and the 5.3L is now in the Chevelle sporting the factory truck intake manifold, 80 lb. fuel injectors, a Holley LS swap oil pan, and a sweet VS Racing turbo hanging off the front passenger side. Matt even built his own crossover and down pipes.

Watch Matt’s Progress

There is still a lot to be done, but we’ll be bringing you updates on this project as Matt works toward his goal of 500 horsepower. In the meantime, visit the MC Motorcycle Repair YouTube channel and watch all of the current build episodes.

Oh, and grab some drinks and snacks—you’ll be watching for a while.

love it biker guy

I appreciate this info. New to all this. I’m going to begin a project I’ve never been into and this has helped me to choose a 5.3 Vortex from a 2011 Silverado to build for my 62 C10 Fleetside Shortbed Big back window. Looking forward to project. Thanks. Trucker Ray ✝️