Quick, what is the one thing every motor needs?

The answer, as always, is BOOST!

What if your motor already has boost, like the junkyard, supercharged 3800 Series-3 V6 we pulled from the local wrecking yard? I mean, it already has a supercharger, so we are good, right? Yes, and at the same time, a resounding no! You see, having a supercharged V6 is head-and-shoulders better than having a naturally aspirated V6, but that doesn’t mean the boosted V6 can’t respond to even more boost.

Back in part 1, we added boost the way most performance enthusiasts go about it, by increasing the blower speed with smaller blower pulleys. This naturally resulted in more boost and (not surprisingly) more power. But there are limits to the power available from the factory M90 supercharger, and while we were not at the flow (or rotor speed) limit of the blower, we decided to go a different route here in part 2.

To further improve the flow and power potential of the supercharged V6, we decided it needed a turbo, and not in place of the blower, but rather in addition to the blower.

My friends, it’s time for some Junkyard Compound Boost! (Oh, and if you long for video footage of all this testing, check out the Richard Holdener YouTube Channel.)

Not sure on the difference between a supercharger and turbocharger? Read this.

A Quick Refresher Course

Backtracking a bit, we previously pulled this Series-3 L32 3800 motor from a 2004 Pontiac Grand Prix GTP. Thanks in part to the Gen-V M90 blower, the L32 was rated at 260 hp, a 20 horsepower increase over the previous L67 3800. Our junkyard L32 was not without its hurdles, as the stock heads were removed and repaired (valve job and seats) after initial testing revealed low power production.

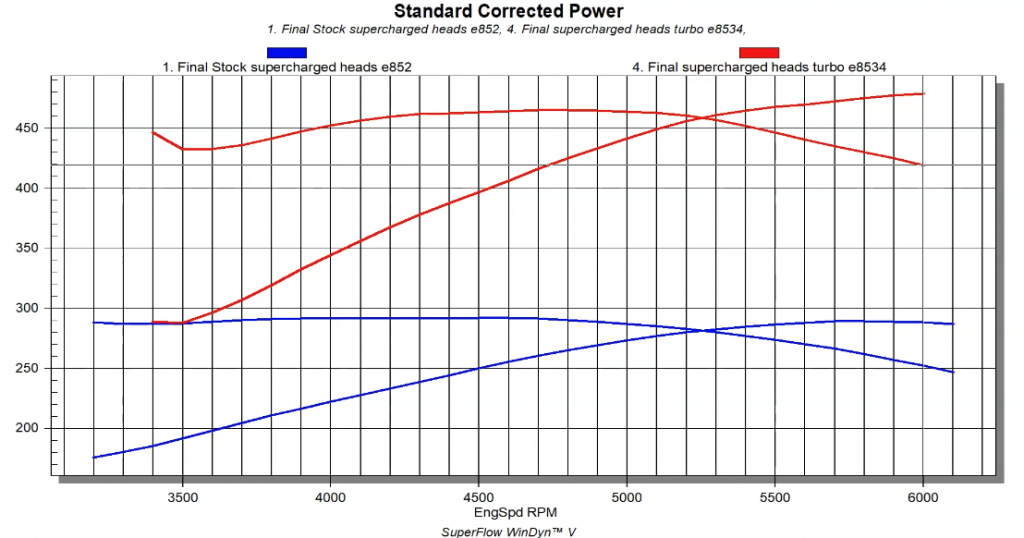

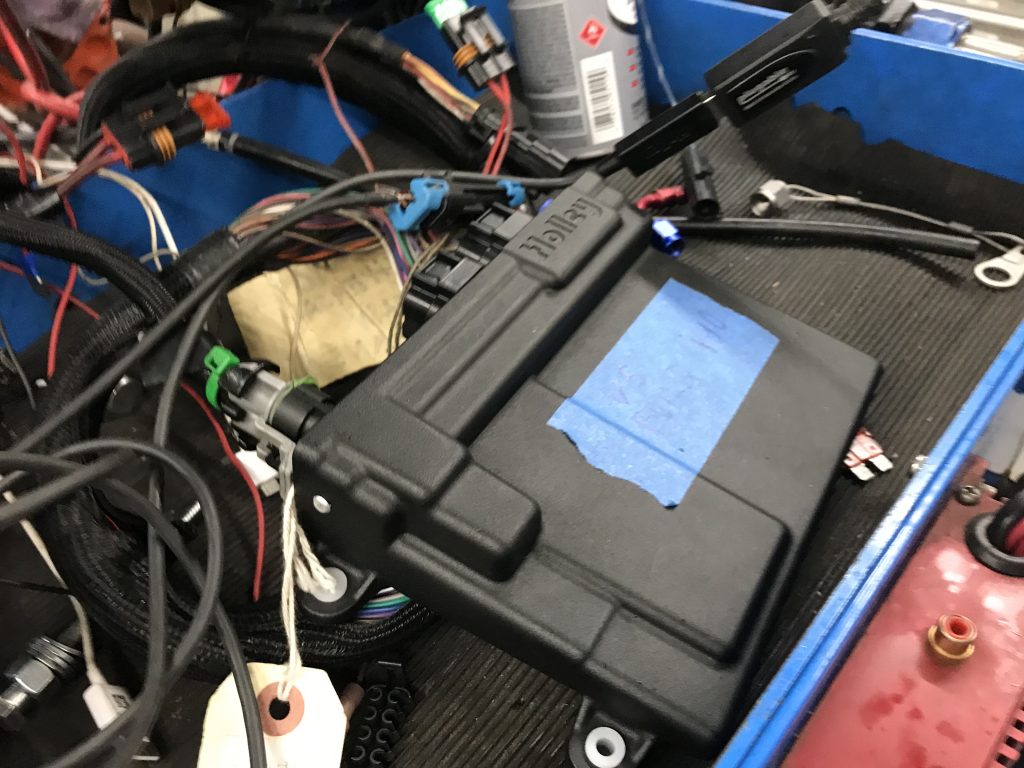

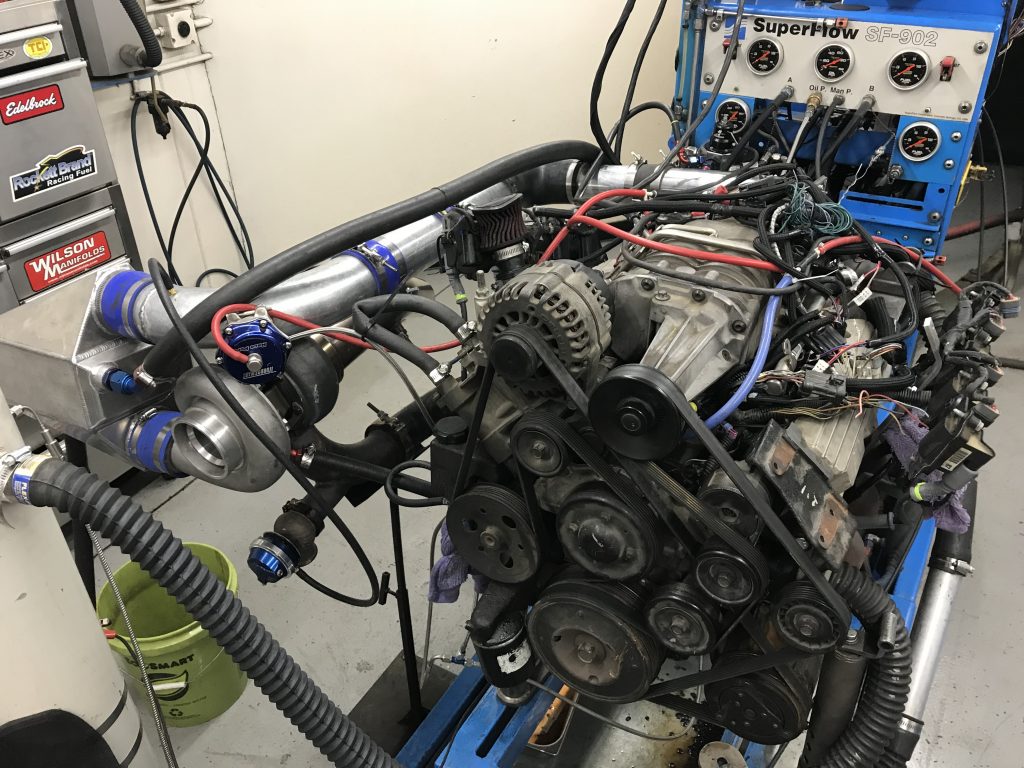

Fixing the heads resulted in a sizable power gain (video available), but we wanted to make sure we had a healthy candidate for testing. Prior to this adventure, the fuel system on the supercharged L32 was upgraded with a set of 80-pound Accel fuel injectors. This allowed us to safely explore the higher power levels using the extra fuel flow required when running E85. For this test, the motor was configured with the stock Gen-V blower and pulley along with the stock manifolds and cross over pipe, feeding our three inch dyno exhaust (no muffler). Tuning was via a Holley ECU, with air/fuel kept near 11.7:1 (on the gas scale) and the timing (in supercharged trim) starting the load with 18 degrees and rising up to a peak of 23.5 degrees. Equipped with just the supercharger, the 3800 produced 289 hp and 292 lb.-ft. of torque at a peak boost reading of 9.7 psi. Now it was time to add the turbo system!

Turbocharging the Supercharged Pontiac 3800 V6

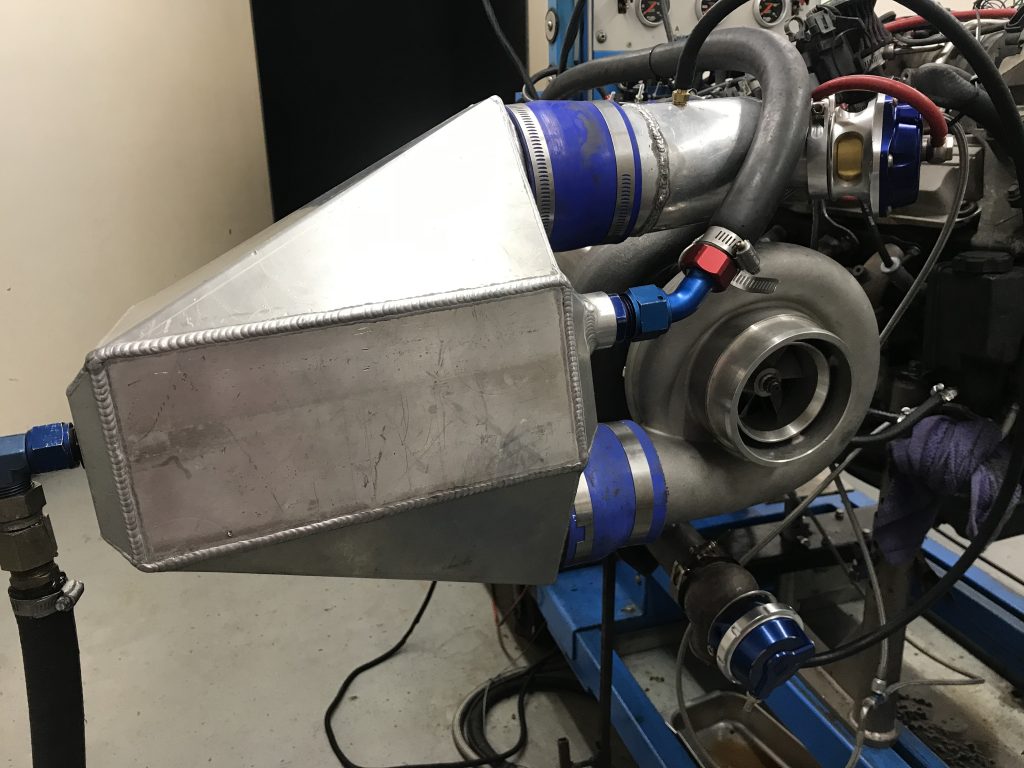

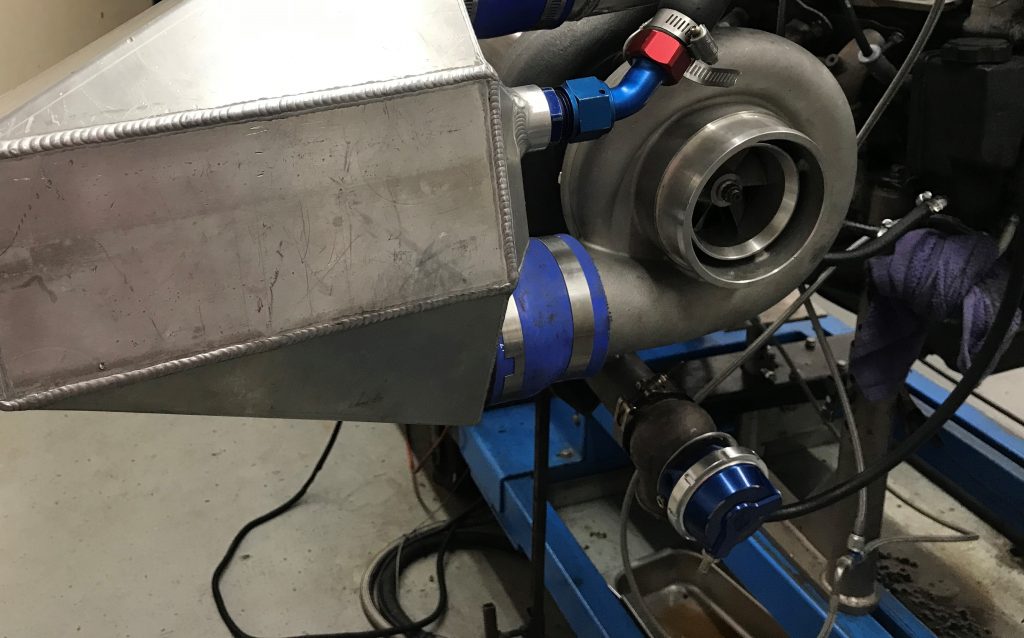

Our turbo “kit” for the supercharged 3800 was actually a simple custom fabricated affair that consisted of a GT45 turbo capable of supporting 700+hp on the right application. Though we had no intention of testing the limits of the turbocharger on this supercharged 3800, it is always a good idea to have more turbo than you need to reach your desired power output. The extra torque offered by the supercharger ensured the compound system would have plenty of turbo response.

To make the compound system work, we needed to feed all of the exhaust from the supercharged combination to the turbo. This was accomplished with s simple three inch V-band clamp. We unbolted the exhaust elbow used on the supercharged motor and bolted on the turbo elbow. The elbow used to mount the turbo featured a three inch V-band fitting on one side and a T4 turbo flange on the other. The 90 degree bend allowed us to orient the turbo facing forward, with the exhaust running roughly parallel to the motor (toward the rear of the dyno cell).

The fact that this GT45 turbo was used previously with this elbow on another application, made installation a snap. The GT45 was previously set up with both and oil feed (T-fitting to the dyno oil pressure gauge) and oil drain (welded fitting in the oil pan (thanks Troy). The only thing left was connecting the 3.5 inch turbo exhaust, the Procharger ATW intercooler and remainder of the 3.5 inch aluminum discharge tube (to the modified factory DBW throttle body).

A few important notes are in order here: The first being the boost supplied by the turbo was controlled by a single Turbosmart wastegate. To ensure the turbo supplied a steady 7 psi to the supercharger, the waste gate reference line was run between the turbo and blower. Running the gate reference after the blower would have it open all the time because the blower (almost) always produced more than 7 psi.

The ATW intercooler was fed ambient dyno water for cooling, but the cooling only took place between the turbo and supercharger.

Some Math & The Dyno Result…

While common sense might suggest that if the turbo supplies 7 psi to the 9.7 psi offered by the supercharger, the result would be a combined 16.7 psi, the compound system actually produced a peak of 23.3 psi.

The reason is that in this compound system the pressure ratios are actually multiplied (7+14.7)/14.7=1.476, then (9.7+14.7)/14.7=1.659, then 1.479 x 1.659=2.453, then 2.453 x 9.7 psi gives us 23.75 psi or pretty close to our measured peak of 23.3 psi.

Close enough, especially since we did not directly log the actual pressure supplied by the turbo.

Math aside, adding the turbo to the supercharged combination resulted in a jump in power from 289 hp and 292 lb.-ft. of torque, to 479 hp and 465 lb.-ft. of torque, at our previously discussed peak boost level of 23.3 psi.

Compound Junkyard V6 Boooost baby!

I just have viewed the YouTube video on this several times, and recently asked a question of you on YouTube, because I just found this blog, which answers many of my questions. My apologies! I do still have a question though, because the gentleman that tunes my PCM for me mentioned the bypass valve on the M90 supercharger. He told me that it should be opened up when the turbo boost level exceeded the M90’s boost level. I know that you are maintaining a 7 psi boost level going into the M90 from the turbo, and that should prevent the turbo boost level from exceeding the M90 boost level, but what, if anything did you do about controlling the bypass valve on the M90?

I have heard that from my tuner also. Try to bore out the bypass hole and put a bigger flapper in. Idk if I could do this since my GenV has already been rebuilt and powder coated. TT from ZZP is my tuner

Dude I am impressed honestly where I come from people all about corn and tractors I love the series too and series 3 3800 one of my favorite platforms it is my favorite platform that thing looks like a monster where to go I like how you have individual coil packs they look like they’re off of a 5-3 V8

He’s supposed to say way to go not where

can this blower be installed on a 4.3 non-vortec engine and what changes will need to be made?

Hello

I have Toyota Cressida model 93 GL

I want buy motor twin cam 24 valve intercooler turbo

Do you have this type of motor or can you help me find this motor?

Thanks