Remember when fuel hose was just fuel hose? It was made of rubber and worked just fine with the gasoline formulations of the day. If you needed some new hose, you went to the parts store and they cut the length you needed off of a big spool. Life was good.

Modern Fuel Chemistry & Its Affect on Fuel Hose

Life is still pretty good, but choosing the right fuel hose has gotten a bit more complicated. The main reason why is the makeup of modern fuels. For example, ethanol blends and additives like benzene and toluene are often used to increase the octane level of gasoline—but will also suck the oils out of your rubber hose.

That dries out the hose, making it brittle, stiff, and prone to leaks. And as the hose degrades, small particles of rubber get into the fuel and plug up fuel filters, fuel injectors, and carburetor passages.

Then there is the issue of permeation, which is fuel vapor that evaporates through the hose walls. If you’ve ever walked by a car in the garage and smelled gas, that’s probably permeation. Even if you like the smell of 93 octane, environmental regulations label that vapor as a pollutant and require the use of low-permeation fuel hose in all new vehicles to control it.

How to Tell the Difference Between the Types of Fuel Hose

You can’t judge a fuel hose by its cover—you have to read the label. Quality fuel hose is marked with an SAE number that indicates what type of material it is made from and what the hose is rated for.

If you look at a fuel hose you will see the letters “SAE” followed by the number 30 or J30, the letter “R,” and a number. The number after the “R” refers to the construction, chemical resistance, permeation, temperature range, and other hose specifications.

SAE 30R6 and 30R7 Hoses

These hoses were the industry standards for decades. SAE 30R6 and 30R7 hoses were designed for fuel systems rated at 50 PSI or less of working pressure like carburetors and TBI fuel injection. The hoses have a nitrile rubber inner liner reinforced with single-ply braided cord and a neoprene rubber cover. SAE 30R6 and 30R7 hose is not compatible with ethanol and many modern additives designed to boost gasoline octane.

SAE 30R9 Fuel Injection Hose

As the name implies, SAE 30R9 hose is designed for use with EFI systems that use hose clamps and have working pressures of 100 PSI and up. It features a fluoroelastomer inner liner that can handle all types of fuel including oxidized gasoline, diesel, methanol, and ethanol-blend fuels. SAE 30R9 hose also resists fuel permeation so it’s emissions-legal.

Replacing old fuel hose with SAE 30R9 fuel injection hose is the smart play. The small price difference compared to SAE 30R6 or 30R7 nitrile hose is well worth it.

SAE 30R10 Submersible Hose

Submersible hose is specifically designed for use in fuel tanks. You’ll typically find it on in-tank fuel pump modules. It has special layers that prevent the inner liner from becoming saturated with fuel.

Just don’t use 30R10 hose anywhere it will not be submerged in fuel as heat will rapidly destroy it.

What About AN Hose?

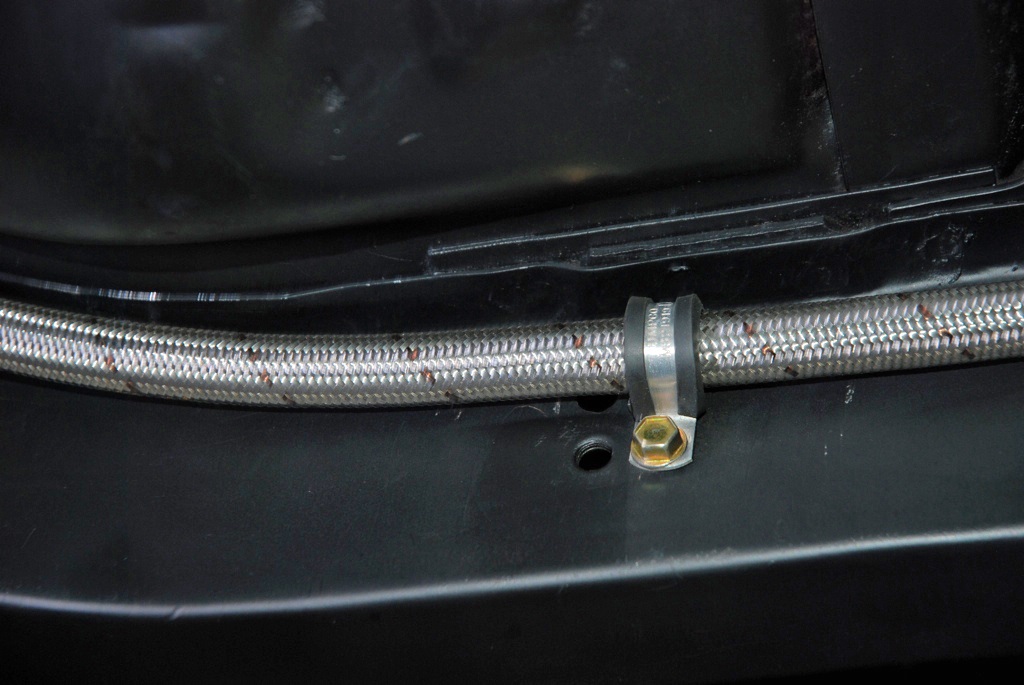

Braided AN hose can be used on street-driven vehicles, but you have to check the specifications closely. AN hose that is rated SAE 30R6 or 30R7 uses the same nitrile rubber inner liner as its rubber hose counterpart and has the same issues with fuel permeation and compatibility with ethanol and gasoline additives. Hose with a chlorinated polyethylene (CPE) synthetic rubber inner liner is not compatible with ethanol and ethanol-blend fuels.

The AN hose you want has a polytetrafluoroethylene (PTFE) inner liner. Better known as Teflon, PTFE is a synthetic resin that won’t react to alcohol or chemical additives in fuel, resists fuel permeation, can handle very high pressure, and has a very high tolerance for heat. The main issues with PTFE hose are the expense and the need to use fittings made specifically for it.

Fuel Hose Installation Tips & Other Notes

Do not replace long runs of hard line with flexible hose. It is more susceptible to damage from road debris, and it can be difficult to seal the connection between the metal line and the hose in fuel injected applications where line pressure is more than 50 PSI.

Resist the temptation to use inexpensive worm gear clamps. They will damage the outer layer of the hose and are not rated to handle line pressures found in fuel injection systems. Use clamps made for fuel injection instead, even for low-pressure carbureted systems. The clamps provide uniform pressure around the hose for superior sealing and have a nut-and-bolt design that won’t damage the hose.

Make sure the hose isn’t too long. Long lengths of hose tend to kink and cut off fuel flow. This is definitely a place to measure twice, cut once.

To avoid a gas shower when replacing hose in a fuel injection system, you will need to relieve the pressure first. You can do this on most vehicles with EFI by removing the fuel pump fuse or relay and running the engine until it shuts off. It’s then safe to disconnect the hose.

While you’re mucking about with the fuel system, you might as well change the fuel filter. It’s not hard and it will be one less thing to worry about.

More Reading on Fuel Hose & Hard Lines

Want to dig deeper? We’ll include some more links on the topic below.

- Ask Away! with Jeff Smith: What You Need to Know About Ethanol, Fuel Blends & Your Fuel Line

- Mailbag: Choosing Fuel Lines for a Street Rod Build

- Mailbag: Tips for Properly Routing Fuel Lines

- Fueling Around: Ideas for Routing Fuel Lines

[…] constant no matter where the fuel hose ends. Don’t pass up this opportunity to get this high-quality fuel hose; order right […]

Hi. I am looking to replace the expensive factory fuel line system in an 1993 gmc truck with an cheaper alternative. Can i safely use an aftermarket silver and red or blue type hose for the lower flex bend between the motor and the frame? And just use pre cut and flared metal fuel line with threaded ends? Or use something else entirely? Thank you.

What about the nylon kits you can buy for replacing the entire fuel line are they any good or should I just go back with steel lines

Hey Steve, it depends on the application. Click here to contact the Summit Racing tech folks. They’ll help you find a fuel system plumbing setup that’ll suit your specific vehicle’s demands.

No one is talking about petrol fuel lines for very small 2 cycle engines where ethanol gasoline is mixed with an oil in the ratio of 33 to 1 or 50 to 1. Ethanol is dissolves some plastics and oil has a bad affect on some plastics. I see petrol fuel lines advertised but are they good for this combination of three chemicals. Also, what type of specific plastic is best where a clear and flexible line is needed?

Hey James, you might want to check out hose that meets the SAE 30R9 standard, as it is compatible with ethanol. This hose from Continental may work for your application.

I am looking for the source (mfg) of the braided fuel line with spiral tracer shown in the last photograph of the Buyer’s Guide: How to Pick the Best Flexible Fuel Hose for Your Vehicle. Do you have details of that hose and can share? Excellent article with specific details that must be adhered to.

I look forward to your reply.

Dick Wells

CWO-4 USA, Retired

Captain, Delta Airlines, Retired

Hey Dick, thanks for the question. That particular pic is from OnAllCylinders contributor Wayne Scraba’s race-prepped Chevy Nova drag car. I reached out to him with your question, and he told me that, on this particular car, he used Earl’s Perform-O-Flex Hose and you can find more details on it here.

…

He also mentioned that he’s used Aeroquip hose on previous cars too.

…

Hope this helps!