I have a big block Chevy in my 1965 Bel Air and it runs great but has a very noisy starter motor. I am using a late model, permanent magnet small starter motor. We recently replaced the flexplate (which was really chewed up), but the starter still sounds nasty when it cranks. We tried one and then two spacers in between the starter and the block but that didn’t help much. Do you have any recommendations?

E.S.

This is kind of a chicken and egg issue as to what originated the problem. You didn’t mention the length of time and how many cranking sessions the new starter had on the old flexplate, but our guess is that whichever started the original problem, the issue now is that both the flexplate and the starter drive gears were damaged. When you changed the flexplate, the starter drive gear teeth were probably also damaged.

The obvious solution is to replace the starter drive as soon as possible before it begins to chew up your new flexplate. But let’s say that the flexplate is in good condition and you have now changed to a new drive mechanism. Even if the starter now sounds good, you still should check for proper clearances or it is possible the problem may reappear.

To begin, the first thing is to verify that the ring gear is not out-of-round. Budget flexplates can suffer from this problem or the mounting surface of the crank may be rusty or have a burr on the shaft that was not checked before installation. The flexplate should be checked in at least four to six positions to ensure it is both round and offers a consistent ring gear position front to back.

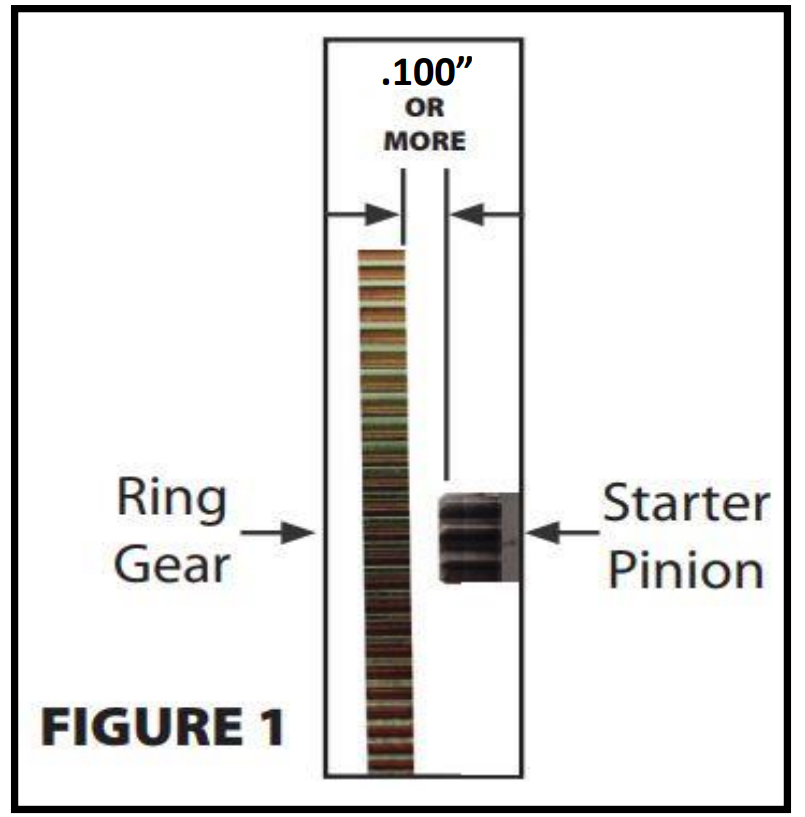

There should also be at least 0.100 inch between the end of the starter motor gear and the flexplate. Some aftermarket starters will come with a shim that can be placed between the aluminum adapter plate and the starter motor body. This shim adds clearance if the starter nose is too close to the ring gear.

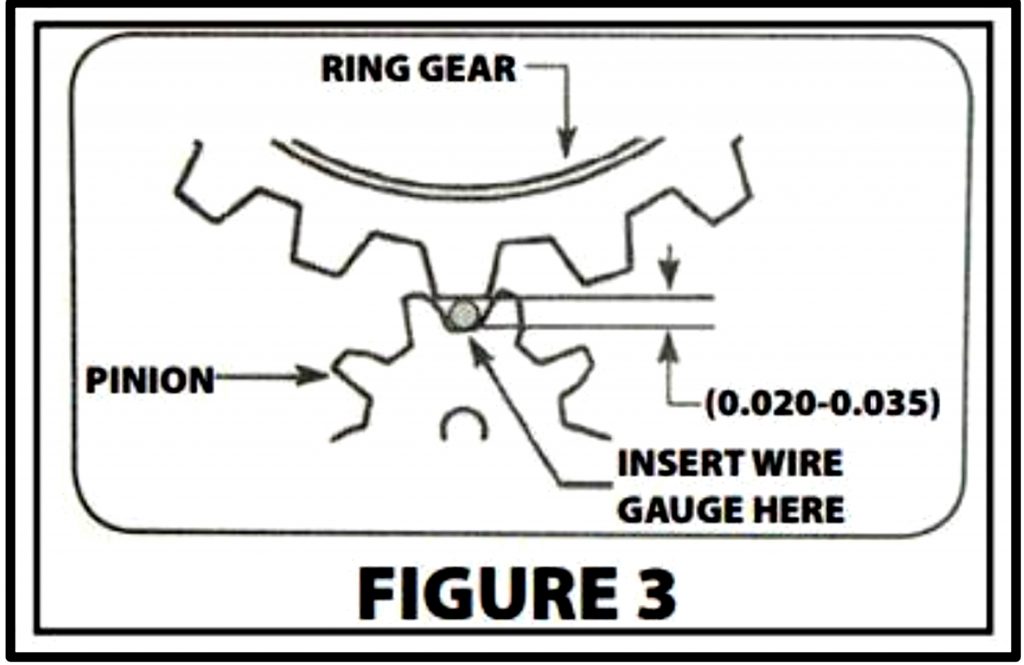

Next clearance to check is the actual gear clearance between the starter motor gear and the ring gear root. The common measurement tool is a #1 small paper clip that is roughly 0.030 inch in diameter. This should fit between the tip of the starter gear and the root of the flexplate. If the clearance is too tight, this is where shims in between the starter motor and the block can add clearance.

According to Powermaster, a high-pitched whine while cranking is an indication that the pinion gear clearance to the flexplate gears is too tight. A loose clearance will generate a high-pitched noise as the key is released and the gear disengages from the flexplate.

Check your starter bolts, I have one using the correct starter bolts, you will see the bolts are knurled near the threads on the bolt, I found that the bolts when I placed them in the starter on the bench and the knurled portion of the bolt did not go into the hole on the starter nose, therefore the bolt was loose in the nose and offered no support, my starter was getting noisy and suddenly just broke the nose off the starter, it was a new manufacturer for gm unit wit gm part #