There was a time when big block Chevy engines with solid lifter camshafts clattered their way down the boulevards and highways of America. It was a time of big block Chevy engines that combined high compression with four speeds and deep gears to offer the muscle car market exactly what it was craving for—more power and impressive acceleration.

Summit Racing also has muscle car camshafts for small block Chevys, along with muscle car camshafts for Ford, Mopar, Oldsmobile, and Pontiac.

The big block Chevy version of that whole muscle car movement involved some very serious engines starting with the 1965 original canted valve head 396 and 427, and into the early 1970s with the 454. While the original big blocks were somewhat tame with 325 horsepower and mild hydraulic lifter camshafts, it wasn’t long before mechanical flat tappet cams pushed the power envelope up, along with the displacement.

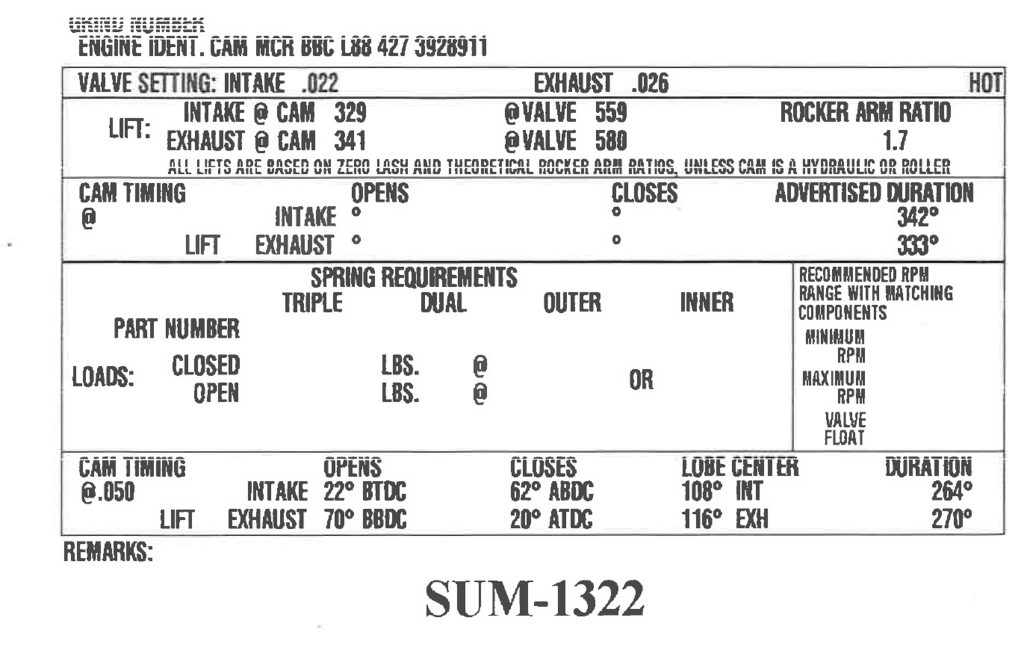

Summit Racing has chosen three flat tappet camshafts to reproduce with very similar but not always exactly the same specs. So if the specs listed here are not exactly the same as your research indicates, the reason is these Summit Racing Muscle Car Replacement Cams employ more recent lobe technology that will likely out-perform the originals while still delivering that original idle sound. As a further point of reference, Chevrolet originally listed its specs for the L-88 with checking points at 0.020 inch tappet lift, while the Summit Racing Muscle Car cam advertised specs are at 0.006 inch tappet lift.

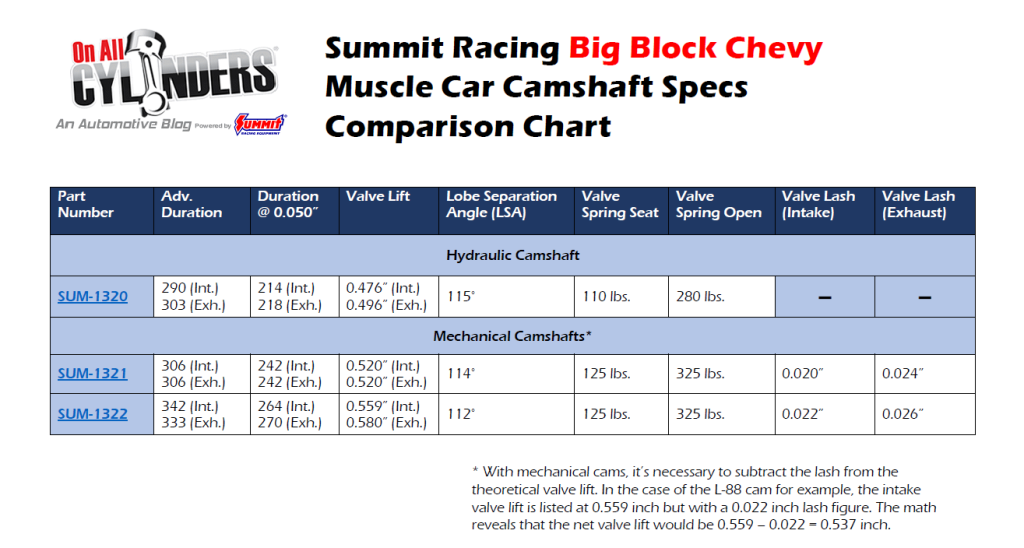

The mildest of the three reproduced cams is equivalent to the early L34 396 hydraulic flat tappet cams used in Chevelles as both 396 and 402ci big-blocks engines. The L36 427 Corvette engines also used this cam. This Summit Racing version would be a wise choice for a mild 396/402/454 where the builder wanted to imitate an early flat tappet cam with relatively mild idle characteristics. This cam sports 214/218 degrees of duration at 0.050 inch tappet lift with 0.476 / 0.496 inch valve lift and a wide lobe separation angle (LSA) of 115 degrees.

The popular 375 horsepower 396 cam is also represented with a Muscle Car cam reproduction. This mechanical cam was first used in the early high output 396 Chevelles and appeared again in the LS6 454 engine found in Chevelles and Corvettes. This cam checks in at 242/242 degrees at 0.050 with 0.520 inch lift on both the intake and exhaust, and a LSA of 114 degrees.

Before we get into more details, if you are not familiar with the cam specs it might be helpful to take a moment to read our story on how to read a cam card that will illuminate the definitions for each of these specifications. You can find that story by clicking here.

The lobe separation angle (LSA) deserves some closer attention because it is often misunderstood. The LSA is defined as the angle between the exhaust and intake lobe centerlines and determines the amount of overlap. A narrow LSA of 110 degrees, for example, is intended to increase the amount of overlap which improves mid-range and top-end power but sacrifices idle quality. A wider LSA of 115 degrees, as used in the L34 version cam, reduces overlap and improves idle quality.

The L-88 Muscle Car cam listed below employs an LSA of 112 degrees which when combined with its longer duration will offer quite a bit of valve overlap. This wider LSA spec is often used to smooth the idle quality in engines with longer overall duration numbers. The L78 cam, for example uses a 114 degree spec.

The LSA spec is not actually listed on the cam card but can be quickly calculated by averaging the intake and exhaust lobe center line figures. For example, if the intake centerline is 110 degrees and the exhaust is 114 degrees, adding them together and dividing by two will determine the LSA: 110 + 114 = 224 / 2 = 112 degrees LSA.

Related to each cam’s specs is the issue of static compression. With a longer duration camshaft, the cam will naturally have more overlap—a condition where both the intake and exhaust valves are open at the same time. Increased overlap at idle is what creates that distinctive choppy idle sound that is coveted by car builders. This overlap also causes a loss of cylinder pressure at lower engine speeds which can be partially compensated for with added static compression ratio. These longer duration camshafts like the LS6 and L-88 designs were originally accompanied with higher static compression ratios.

The original L-88 aluminum head big block Chevy featured a 12.5:1 compression ratio while the LS6 reduced that slightly to 11.25:1. These high compression ratios were also supported with much higher octane fuel back in the day. These ratios are a bit unrealistic with today’s 91 to 93 octane pump gasoline. This means the selection of the L-88 cam with a static compression ratio of 10.5:1 since this will probably not make as much torque as the engine could have with a higher static compression. So it’s important to consider all these variables before investing in the L-88 cam. Of course, if you have access to high quality fuel, then the higher compression ratio is certainly beneficial.

Another important point when considering a flat tappet camshaft is to prepare for the break-in period. This is when the cam lobe and lifter must create a wear-in pattern. This occurs most often within the first 10 to 15 minutes of engine operation. Coating the cam lobes and bottom of the lifter with the supplied high-pressure moly lubricant ensures that the first few moments of engine operation are properly lubricated.

Jeff’s written a more in-depth article on the topic. If you’re interested, read this: Eccentric Ways: The Best Way to Break-In a Flat Tappet Camshaft

Of course, the proper oil is also important because standard off-the-shelf oil has drastically reduced the high pressure lubricants like zinc and phosphorous (generally referred to as ZDDP, which stands for zinc dialkyldithiophosphate). Summit Racing has a high quality SAE30 Break-In oil that includes the proper levels of ZDDP along with minimal detergents that actually work against the break-in process.

Once the engine starts, it’s important to immediately bring the engine speed up to between 2,000 and 2,500 rpm. This ensures that oil splash from the crankshaft will lubricate the cam while the engine is running through its initial break-in period. Camshafts are not pressure lubricated but only splash oiled by the oil flung off the crankshaft. This is why an engine speed well above idle is important to ensure sufficient lubrication.

Another important consideration for break-in for any flat tappet camshaft, either hydraulic or mechanical is the valve spring pressure. This is even more important for high performance big blocks because they generally call for dual springs with higher valve spring loads. We’ve noted the suggested valve spring loads at both seat and open pressures. This is often achieved with a dual spring configuration so the recommendation is to remove the inner spring for the initial break-in period to reduce the load at max valve lift. Once the cam has successfully completed the break-in period, then the inner springs can be re-installed. This requires a bit more effort but also greatly increases the chances that the cam will wear in properly.

We’ve included a Comp dual spring part number in the parts list that is intended for flat tappet hydraulic and solid lifter big blocks. This dual spring (part number CCA-924) is very close to the recommended spring loads and because it is a dual spring, this makes it easy to reduce the load during break-in by removing the inner spring. Single wound springs don’t offer that opportunity which makes the dual spring a much smarter choice.

Taking all the ideas presented here into consideration is part of process for selecting a camshaft for your next big block Chevy project. But regardless of which cam you choose, these Summit Racing Muscle Car cams offer a quick way to relive some of those past glory days of the big block Chevy.

***

Summit Racing Big Block Muscle Car Camshaft Part Numbers, Specs & Comparison Chart

We’ve included a chart below, but CLICK HERE if you want a downloadable/printable PDF comparison spec chart of all the Summit Racing Big Block Muscle Car Camshafts.

***

Summit Racing Big Block Muscle Car Camshaft RPO Code Conversion Chart

The following chart reveals the equivalent Summit Racing Muscle Car Replacement Cam part number to the original Chevrolet Regular Production Order (RPO) number engine description:

| Chevy Part Number | RPO Number | Summit Racing Cam Part Number |

|---|---|---|

| 3883986 | L-34/36 | SUM-1320 |

| 3904362 | L-78/72 & LS6 | SUM-1321 |

| 3928911 | L-88 | SUM-1322 |

***

Summit Racing Big Block Muscle Car Camshaft Parts List

- Summit Racing Muscle Car Cam, L34/L36 – SUM-1320

- Summit Racing Muscle Car Cam, L78/L72/LS6 – SUM-1321

- Summit Racing Muscle Car Cam, L88 – SUM-1322

- Trick Flow Hydraulic Flat Tappet Lifters, BBC – TFS-21400001

- Speed-Pro Mechanical Lifters, BBC – SLP-AT-992

- Comp Mechanical Lifters, BBC – CCA-813-16

- Comp Dual Valve Springs – CCA-924-16

- Comp Steel Valve Spring Retainers- CCA-741-16

- Summit Racing Double Roller Timing Set, BBC – SME-7010TS

- Summit Racing 30 Grade Break-in Oil – SUM-1-SAE-3

- Summit Racing Muscle Car Oil 10w30 – SUM-1-10W30

- Summit Racing Oil Pump Primer – SUM-901015

- Summit Racing Cam Degree Wheel – SUM-G1057-16

I belive there’s a mistake in the applications for SUM-1321. Wasn’t the L79 a small block (327) engine? I’m thinking that the it should list the L89.

Hey Mike–good catch. It’s the L78 Cam we’re talking about here. We’ve made the updates in the story. Thanks for the heads up!