A few weeks ago, we ran an article on the Lineman’s Splice. While that particular splice has proven reliable over decades of use, it is a bit labor intensive and requires some learned soldering skills, which means it can be difficult to make a proper Lineman’s Splice in a tight space where there’s limited access to the wires.

Thankfully, our amateur radio pals over at DX Engineering have an easier solution.

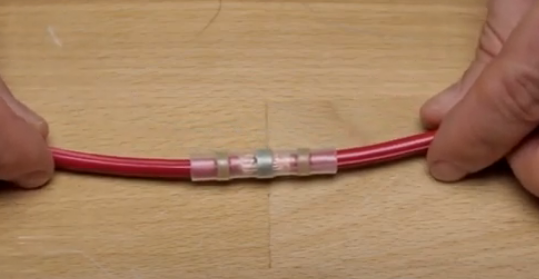

Its Heat Shrink Self-Solder Wire Splice Connectors simply slip over the wire splice joint, then all you do is melt the connectors with a heat gun and, voila, your connection is made.

You can also get similar connectors in an assortment pack from Summit Racing.

How Do Heat Shrink Self-Solder Splice Connectors Work?

Simply push your stripped, stranded wire ends together, slip one of these connectors over the joint, and hit it with a heat gun for a few moments.

The heat will melt the low-temp solder between the stranded wires to create a solid electrical connection, while simultaneously contracting the heat-shrink tubing to reinforce the joint and make a weatherproof shield over the splice.

They’re a smart solution for anyone who has to make a ton of wire connections and wants to speed-up the process.

Better still, the foolproof design of these connectors eliminates many issues caused by faulty connections as a result of moisture ingress and physical strain/vibration.

Here’s a video that demonstrates how they work and how to install them.

Comments