Older cars and trucks are often packed with ingeniously simple solutions to potentially big problems. And we got reminded of that recently when it was time to replace the fuel filter on an AMC 258 tucked in a Jeep CJ.

Though the engine was running fine, it had been quite a while since we changed the fuel filter and it was easy, cheap maintenance.

Now here’s where it gets interesting.

The fuel filter for this application features two outlet ports—one leads to the carb and the other is a fuel return line that leads back to the gas tank.

The reason for the secondary return line is beautifully simple: It serves as a sort of makeshift fuel regulator to ensure the carburetor doesn’t see too much fuel pressure.

This setup isn’t unique to Jeeps either, as you may find it in other vehicles (particularly older trucks).

As an added benefit, the secondary return line helps prevent fuel vapors from building up inside the fuel system too, which can cause vapor lock and create hard-starting issues. Those vapors are simply purged back to the tank.

Here’s How the Dual-Outlet Fuel Filter Works

The 258’s got the typical mechanical fuel pump setup that’s driven by the engine. The pump pulls fuel from the tank into the pump body before sending it up to the carburetor.

But right before the carburetor is the dual-outlet fuel filter. The single line goes in one side, and on the other side, the center outlet barb connects to the carburetor and the smaller one goes to the return line.

The key here is to install the fuel filter so that its second outlet (the return) is at the 12 o’clock position, above the center outlet port.

In that orientation, fuel will fill the filter’s cavity before it heads to the carburetor via the center outlet—nothing fancy there.

But in situations where the engine doesn’t require that much fuel, the fuel filter will gradually fill up. Once the excess fuel reaches the secondary return line, it’s simply sent back to the gas tank to be cycled through again. That prevents the carburetor from getting too much fuel pressure. (The Carter BBD carburetor in this application likes to see around 4 psi.)

Super simple. Super-er effective.

On the Flip Side Though…

But that also means you’ve got to make sure that secondary port is clocked above the main center carburetor feed line.

If you don’t, fuel’s going to be constantly dumped back to the fuel tank, potentially starving the carburetor and causing plenty of hard-starting, lean-running situations. (We’ve heard nightmarish tales of folks spending tons of time and money to solve fueling woes, only to have it fixed by a half-twist of the fuel filter.)

So if you’ve got an older, carbureted engine, pop your hood and check if it’s got a dual-outlet fuel filter. Then take a closer look at its orientation—it might save you a ton of headaches, particularly if you’ve been battling a hard-starting, rough idling engine.

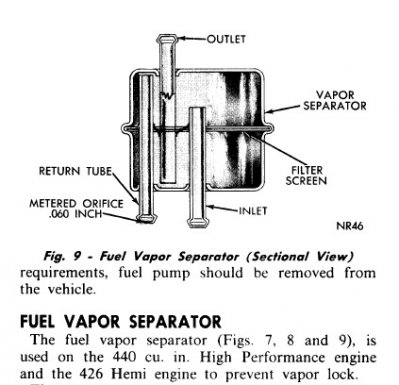

440 Mopars came from the factory with a fuel canister/ filter mounted vertically with the return line on the bottom of the canister.How does that work compared to the horizontal mount in your article?

Check out the picture below that I found on the ForBBodiesOnly Mopar forum. And yeah, it looks like the same basic principle, just with a different orientation.

This looks like setup in a 1974 Jensen Interceptor and can’t work out how that works when the return is at the bottom and outlet to carb at the top. Surely would lose a good deal of fuel just falling out the bottom. Problem with fuel getting to carb but when turning over the engine get a flow straight away from the overflow. Want to know if having the separator horizontal would help.

It’s not surprising that the Jensen’s setup is similar. The illustration above is from a Chrysler shop manual–and Interceptors, I think, used Chrysler engines.

…

Take a closer look at the pic, the return “dump” port tube extends all the way near the top of the filter housing, which means it’ll only start returning fuel when the chamber fills up entirely. Conversely, the outlet tube inlet (feeding the carb) extends down all the way to the bottom, so it’s sucking up the fuel from the floor of the chamber. Make sense?

Thank you Paul, you save my jeep running well

If your tank has a vent line running up under the hood, like my 340 Dart, can it be converted to this return libe?

Hey Bill, check out my reply to Brian above–he also asked about a Mopar. If that’s a similar setup to your Dart, then it looks like the vent line already does somewhat act as a return line.

Or are you saying your vent line is open and venting under the hood (not going back to the tank)?

Holly crap, Im checking this out tomorrow!!! This just might be my problem.

Let us know how it goes Marcus–good luck!

Working on a 76 cj5 with 4.2 liter three port fuel filter is oriented as you suggest but with engine running fuel pouring out of vapor port immediately . Only expecting a small amount not the case. Is this normal?

Does it run OK? Is everything stock? Does it continue to dump fuel as you rev the engine? I can’t say for sure because I’ve never unplugged my vent line at idle, but I’d suspect that, at idle, the fuel pump may be sending more fuel that the carb can expend, which would result in the excess returning to the tank. Once the RPM climbs, the fuel delivery becomed adequate for the increased engine speed.

…

However, if it just doesn’t seem right, it’s worth checking for issues upstream, particularly if you notice the engine is not running properly or a strong gas smell when it’s idling–things like kinks or pinches in the line, improper carb float levels, etc.

…

And make sure your fuel pump is correct–Excess fuel entering the carb can result in a rich-running situation. Black fouled plugs, a rough idle, and a strong gas odor are all indicative of something like that.

I have a 1976 AMC Hornet W/ 232 ci with one inlet and two outlet fuel filter my engine was running rough at idle, smelling gas fumes in the cab. But I was experincing a loss of power on acceleration from stop. I found an article on this fuel filter. I found filter was not installed properly. Simple fix problems solved. I was amazed. Thanks For The Comments Guys, clearly helped my Auto problems.

Could this type filter be used as the return line for a TBI fuel injection system that runs at around 11 psi ?

Hey Ronald, without knowing all the details behind your specific setup, I’m inclined to say no. Here’s why:

On a return-style fuel system, the return line must maintain a consistent pressure, which I don’t think is possible with this setup here. This filter is designed for, like, 5 PSI and lower, and you’re doubling that. Opining out loud here, it makes me think that, once the filter fills up thanks to the increased pressure, you’ll end up splitting your fuel supply almost 50/50 here, sending just as much back to the tank as you are to the fuel rail.

Plus, as a general rule, the return line should be at least the same size (if not one size bigger) than the supply line–and for this particular filter, the return line is smaller.

Thanks for reading, hope this helps.

Hi Friends and Mr Paul, I have a 1952 Studebaker champion 6 V six cylinder. I think it suffers from vapor lock. Can you please provide any sort of instructions or point me in any direction to install one of these fuel filters with a return line to the gas tank. I’ve heard from a few people that this would be a good fix for the problem I’m having. I’m not a mechanic just a preschool teacher learning as I go. But I’m happy to learn and keep trying. Thank you for your time and consideration. I’m in Los Angeles.

Aly

Hey Aly, did it have one of these filters originally? I’d be hesitant to add something into the fuel line that wasn’t there from the factory–fuel restriction in the line can actually worsen your vapor lock issue. Instead, I’d try to figure out what’s causing the vapor lock. Check all your fuel lines and their proximity to heat sources.

For instance, examine your flexible line up to the carburetor. If it is touching the exhaust manifold, intake, or the block, it might be creating a hot spot that causes the fuel to vaporize.

Sometimes a simple heat resistant sleeve wrap can make a big difference. And again, if you’ve got a kink or tight bend in your hard line, it could be restricting fuel flow that would increase the chances of vapor lock on down the line.

…

Our pal Jeff Smith wrote a handful of articles on the topic, and they’re worth the read, click below:

Understanding Vapor Lock–and How You Can Fix It!

Revisiting Common Causes and Cures for Vapor Lock

…

Hope this helps, good luck with your Stude!

Hey paul. I got a 1979 cj5 I put a remain motor in it from titan eng fl. Installed DUI dist.Weber carb.fouled out about 10 sets of spark plugs . I got it running with air idle screws out about 1\2 turn . it runs ok. Besides that head gaskets leaks at oil galley. rear main seal leaks. This jeep needs to be worked on more than a Harley I owned in the 70s.not sure what to fix first?

Hey, cool rig! I’m kind of a Nervous Nellie about RMS leaks–something about a sudden catastrophic loss of oil always makes me extra cautious, so that’s what I’d address first.

…

But! Are you sure your leak is coming from the rear main seal? You didn’t specify what engine you’ve got, but for instance, the 258 I6 valve cover is notorious for weeping, particularly near the back. When I got my CJ5, I thought it had a RMS leak too, but once I degreased the engine bay, it turned out to be a nasty leak from the valve cover making it down all the way to the pan–way easier fix than a rear main seal. Just a thought.

…

Good luck with your Jeep!

On a Jeep CJ with the factory set up using the 3 port fuel filter

Was there originally a restrictor inside the “Return Port” of the fuel filter that regulated the pressure to

the carburetor (to/ or close to 4 PSI)?

I’m hearing it both ways, “It used to have this” —- “It no longer has this with more modern

filters on the market.”

OR

Are they simply making the “Port” smaller to make it more restrictive now days?

OR

Is installing a regulator on the return line and a fuel pressure gauge at the carburetor

the only sure fired way to get the correct pressure to the Carter BBD carb?

I’m providing my Holley 390 with 7.5 PSI using the 3 port filter and a regulator on the return

Others say the filter used alone Used to/ or should now provide 4 PSI to a BBD.

I have looked all over for an explanation for a “Restrictor” on/ in the filter.

Can you maybe show any differences from “Back then” to “now” with literature and/ or pics?

Bruce

Hey Bruce, I’ve never heard of a restrictor in the line. And there wasn’t one when I replaced the rubber fuel line a while back–though again, the engine here is a 258 six.

This was the exact Wix filter I used, and it worked fine, but you’ll notice that the return port is indeed a bit smaller. Are you having a problem with fuel delivery on your 390? My first thought would be to set it up without a restrictor, just using the filter and return port to regulate the fuel supply. At the time of this reply it’s still around a $7 filter, so it’s not an expensive test.