When I think back to the 1970s, I think of the controversial inventions Detroit came up with in its quest for fuel economy along with the challenge of meeting tougher federal emission standards. There were GM’s computer-controlled “feedback” carburetors and Chrysler’s Lean Burn “hot bake” processors inside the air cleaners.

There were also Ford’s 2700 and 7200 “Variable Venturi” 2V carburetors.

Despite the best of intentions at the engineering level, these engine “management” systems (both fuel and ignition) didn’t function very well and were cursed with technicians and repair shops that didn’t really know how to service the VV. The main problem was technical knowledge and how to tune this innovative carburetor.

They were not a bad design—just misunderstood.

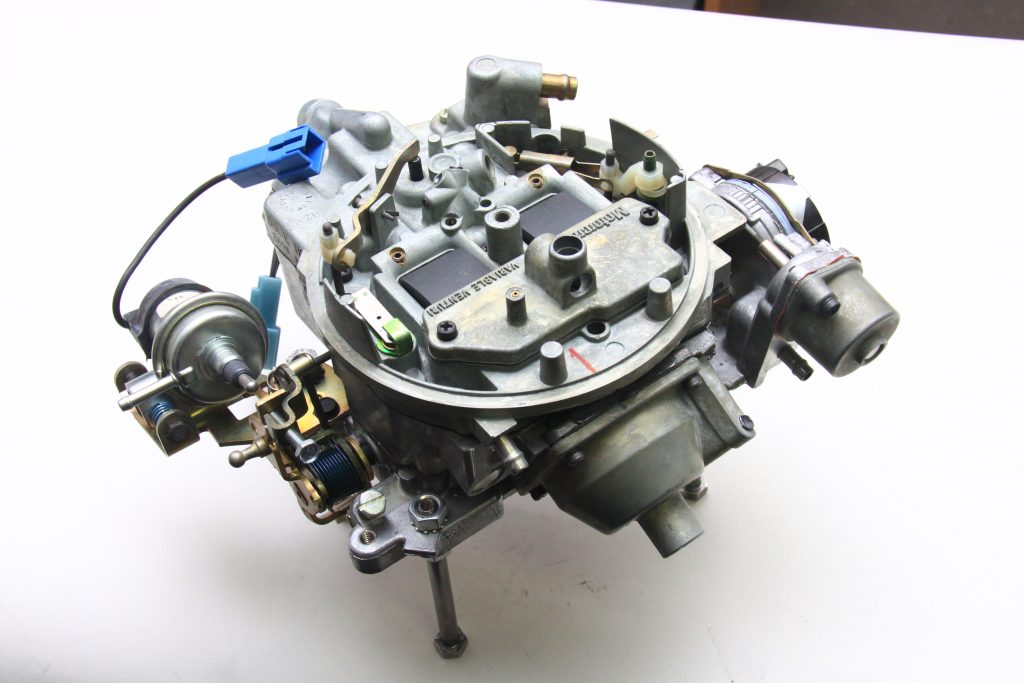

Ford’s Variable Venturi (VV) 2700/7200 Series carburetor was a revolutionary design yet challenging to understand. When it was introduced in 1977, the VV atomizer was befuddling to even Ford technicians who were factory trained in its function and service.

…Now, we’re going to try to explain how the darned thing works.

How the Ford Variable Venturi Carburetor Works

On the surface, the VV carburetor looks like any other two-barrel carburetor—that is until you examine the throttle bores and discover you can’t see them. The venturi valves (which are connected to fuel metering rods) on top of the air horn block your view of the throttle bores when they’re at rest. Open the venturi valves and you can see the throttle bores and plates.

How the VV works is challenging to explain.

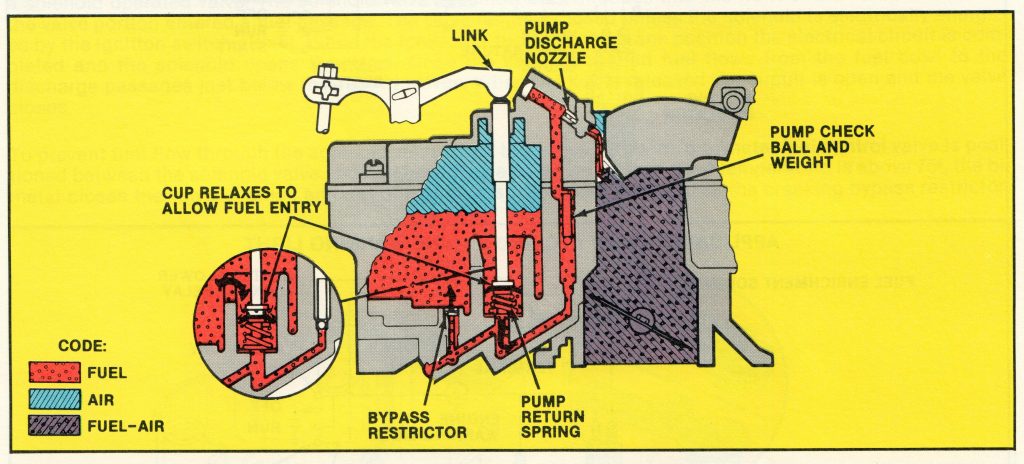

The VV has all the features of a conventional carburetor: a fuel inlet, bowl, and float; a main metering system for off idle function, an idle circuit, throttle plates and bores, and the variable venturi air valves. The venturi valves limit airflow, yet increase velocity depending upon how far they open.

Ford says, “As air flows through a restriction, its speed increases and pressure drops.” This is known as the venturi principle. Ford goes on to say, “In a conventional carburetor, this principle is applied through the usage of fixed venturis mounted in the venturi of the carburetor. In the VV carburetor, the venturi action occurs between the leading edge of the venturi valve and the carburetor casting.”

The venturi valves are actuated by the venturi valve diaphragm at the back of the VV carburetor. The venturi valve diaphragm is affected by intake manifold vacuum, which controls venturi valve function. This enables the venturi valves to match both air and fuel flow to meet any engine demand. The venturi valve looks like a secondary actuator on the Autolite 4100 4V carburetor, only it does something different. It operates the venturi valves.

Now—how this diaphragm operates requires further explanation. Where the diaphragm positions the venturi valves depends on engine speed and load according to Ford. This happens via an intake manifold vacuum signal, which is applied to the diaphragm from the carburetor throttle bore. This happens based on controlled vacuum in the throttle bores. The calibration for controlling this is based upon spring pressures versus the vacuum signal.

Like any carburetor, the VV has an accelerator pump to provide a fuel shot as the throttles open to prevent flat spotting and stalling. In linear fashion, the pump shot creates a rich shot to keep the fires burning as air flow increases. As the throttles close, the accelerator pump bore refills with fuel.

The VV carburetor does not have a choke like a conventional carburetor. Instead, it sports a Cranking Enrichment System. As its name implies, this enrichment system offers a rich mixture for cold starting via a thermostatic coil and fast idle cam to prevent stalling. As the engine warms, the coil brings back the fast idle cam for a normal idle and a leaner mixture. There’s also a choke pulldown diaphragm, which is actuated by intake manifold vacuum.

Changes, Alternatives & Replacements to the Ford VV Carb

Because the VV carburetor tended to be a work in progress, there are a number of changes to be aware of if you happen to be looking for one. Base your selection on the Ford part number and related information on the casting.

An alternative to the VV carburetor is conventional Autolite/Motorcraft 2100/2150 carburetor. Check your local smog laws to see if this swap is emissions-legal in your area.

If you choose to stick with a VV carburetor, the good news is you don’t have to rebuild it yourself. You can opt for a UREMCO remanufactured Ford Motorcraft VV carburetor found at places like Summit Racing, which has been professionally remanufactured under strict engineering standards. Rolling the dice on a remanufactured VV carburetor from your local auto parts store can be risky, and what kind of warranty are they offering you? United Remanufacturing Company (UREMCO) has over 60 years of carburetor remanufacturing experience. They have a terrific team of qualified technicians who have years of collective experience in the field.

All UREMCO Ford VV carburetors get an extensive reman process from disassembly, extensive cleaning, and testing to final assembly and inspection. They don’t need on-engine tuning when installed. Just install, fire the engine, and go. Do a leak check before hitting the road.

I would love to try two in a dual carb setup on a DOHC V8 GM engine.

A guy in town

ran 2 of them on a tunnel ram SBC not super crazy cam…it was really fast for then 11s n 12s… n he laimed close to 20 mpg on hi way…throttle response was like fuel injection now….He machined something on them to make them work great..he wouldnt tell anyone of course..lol…At least 25 yrs ago

Hey Thanks – there’s hope for even a seemingly hopeless atomizer. I like having the courage to try something different.

I worked for Ford when that carburetor came out and let me tell, they work great. Not for performance use, the CFM rating is too small, but for drivability and potential fuel economy…. I have never experienced anything better. They’re really just a motorcycle carburetor with externally adjustable main jets. I had one running so clean on a 360 Ford pickup that the exhaust pipes were white and chalky inside. I don’t remember the exact fuel mileage but I do remember driving on the freeway for over an hour before seeing the gas gauge needle move!

I like your comment. A lot to be learned – which is why I posted the VV – I want to know what people’s experiences were.

Had Country Squire, I think 351-plastic cam gear-replaced from NAPA with metal. Also NAPA was only one to help, as carb shops, others in Columbus, Ohio wouldn’t, OR couldn’t repair/rebuild and make it work. As a factory (Mercury Marine) trained mechanic, I bought rebuild kit-from NAPA- as they were only ones who had. Kit contained ALL necessary parts including PLASTIC pieces for linkage’s as they were the reason for rebuild. Carb basically had to be disassembled to replace broken parts

Your comment said the CFM was low. Like how low, and how do you know this?

Seems to me that without the boosters, etc. in the way ,it would flow more than the 1.08 carb anyway

MY

For Steve @ OC Carbs

Would one work or be mafia to work on a dodge 3.9 V6? I would definitely use one, as it would be vastly better than what it currently has.

I had one on an 81 Mercury Marqui with a 351 windsor that car was Fast and smooth. I was told by a lifelong mechanic they either screamed or they were crap. Mine screamed. Dead of winter negative temps didn’t even have to hit the gas to fire it up. I loved that car.

Befuddling? Confusing? Variable venturi or “constant-depression” carburetors have been invented in the early years of the 20th century. British cars had them since at least the 1920’s – the famous SU-carbs or Zenith carbs.

Now the problem wit that design is that only works as a side-draft carburetor. It is difficult to adapt to a typical V8 that has one downdraft carburetor in the center of the V. (Look at old Range Rovers and you see how they managed to fit SU-carbs to a V8).

So Ford just needed a mechanism that adapts the SU style plunger (which moves up and down) to something that moves sideways in a downdraft air flow. Since the SU plunger is centered in a bore moving up and down, friction is small and it can be moved with the relatively low vacuum created in the intake. Flipping it on its side, the friction would be too high and the plunger would not be able to move anymore. So Ford lets the venturi valves pivot on a point lower in the carb – actually very simple.

The biggest difference to a fixed venturi carburetor is that the venturi effect (local low pressure at the narrowest place in the venturi) is a constant pressure for any amount of air entering the engine. In a fixed venture carburetor, the local low pressure falls at higher air flow. This is why it is used to draw in fuel through a constant opening nozzle.

In a VV carburetor you need to change the nozzle size with the amount of air, otherwise the fuel amount would be decreasing for high load conditions.

This is what the tapered fuel metering rods are for. They close off more area in the nozzle when the air flow is low (less engine load – less air, less fuel) than when the air flow is high (high load/rpm – high air and fuel intake).

If you get the metering rod sizes wrong, or the jet, or the rod position (in SU and Zenith carbs, the rod position is adjustable), you will get a wrong air-fuel-ratio over all engine RPM and load conditions.

So if yours doesn’t run right, you have to adjust it for more than just idle.

It probably is set up by the factory to be non-adjustable (I think that was part of emission regulations back then) so you have to figure out a way to do that.

Anyway, I like the way the system is designed and you can see on carburetor history just how growing demand for car engines flexibility (RPM range, load range, temperature range etc) triggered more and more inventions like this.

(Until all was killed by the electronic fuel injection).

Rob

The jets are adjustable with engine running if you have the tool. They are a great carburetor! 🙂 I ran one on my 78 F-150 with a 351 for a few years before I converted it to fuel injection. If I ever built another 400 SBC (I had a ’69 Pontiac) I always thought 2 VVs would be pretty cool! 😉

This is a really interesting article Jim. I’ve just bought a 1.6 1983 Capri and I can’t fathom out what auto carb I’ve got. It’s a 83JF-KCB P08D?

Do you know if that’s a type of Ford VV carb?