How do we add power to an internal combustion engine? Well, the possibilities are endless, depending on the starting point.

If we take a typical small block Chevy (though these suggestions work on any motor), we can start with improving the airflow of our giant air pump. Using the air pump concept, a motor will make more power if it can process more air from one side of the pump to the other.

How do we improve airflow?

We start with the simple things, like a bigger carburetor, a performance intake, and then toss in some high-flow cylinder heads. The potential problem with all these mods is that they often times only represent potential airflow. Of course, the rest of the motor must first be able take advantage of (or utilize) all the extra airflow.

One way to enhance the airflow usage and power output is to increase the displacement. Bigger motors flow more air and make more power. Cam timing is also critical for power production, as it must work with the induction and cylinder heads to maximize power production in the desired rpm range. Get all of these systems working together, and you have the makings of more power.

Of course there is always boost, but the best combo is to combine the heads, cam, and intake with added compression AND boost! That’s exactly what we did on this Vortech supercharged small block.

The Stroked Small Block Chevy Test Motor

Truth be told, boost and the other mods can be applied to any motor, but we decided to install the Vortech supercharger on a small block Chevy. We have successfully run the centrifugal supercharger on stock, mild, and even junkyard small blocks, but for this exercise, we decided to step things up and run a Stroker combination.

In fact, we stepped up nearly every aspect of this build, including displacement, compression, and airflow.

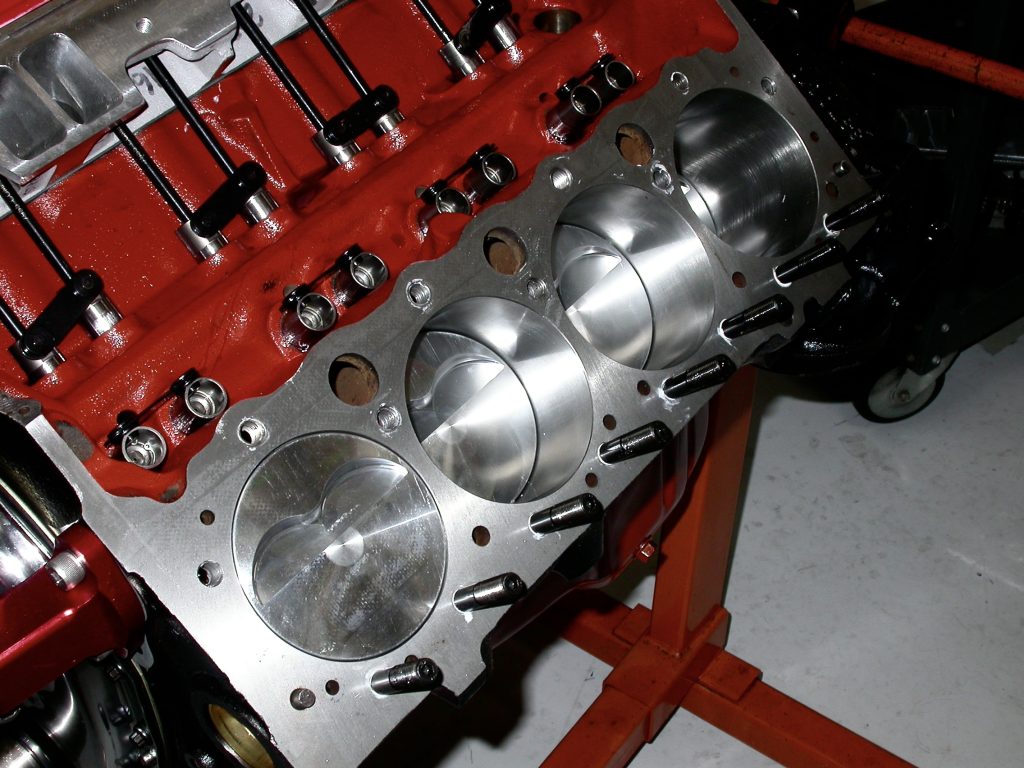

To get things started, we decided against a run-of-the-mill 350 small block. Sure, they can make plenty of power, but we opted to combine a 3.75 inch SCAT Stroker crank with 6.0 inch rods and 0.030″ over, forged flat top pistons to create a 383 Stroker.

When it comes to power production, bigger really is better. The 383 Stroker was further upgraded with a healthy Comp XR294R cam. The retrofit hydraulic roller cam (for our early block) offered a 0.540″/0.562″ lift split, a 242/248 degree duration split and 110 degree LSA.

The valve reliefs in the flat-top pistons offered ample piston-to-valve clearance for our wild Comp cam. In addition to the cam, Comp also supplied the necessary double-roller timing chain, hydraulic roller lifters, and a set of 1.6 ratio stainless roller rockers.

After installation of a HD oil pump, front cover, and oil pan, our short block was complete.

Heads, Intake & Carb Choices for Our Supercharged Small Block Chevy

Given the combination of compression, displacement, and cam timing, the 383 was in need of some serious head flow. After all, the short block is only as good as the induction system. To that end, we installed a set of CNC (comp) ported AFR 195 heads. The AFR heads featured full CNC porting, a 2.05″/1.60″ valve package, and a 0.600″ lift dual spring package.

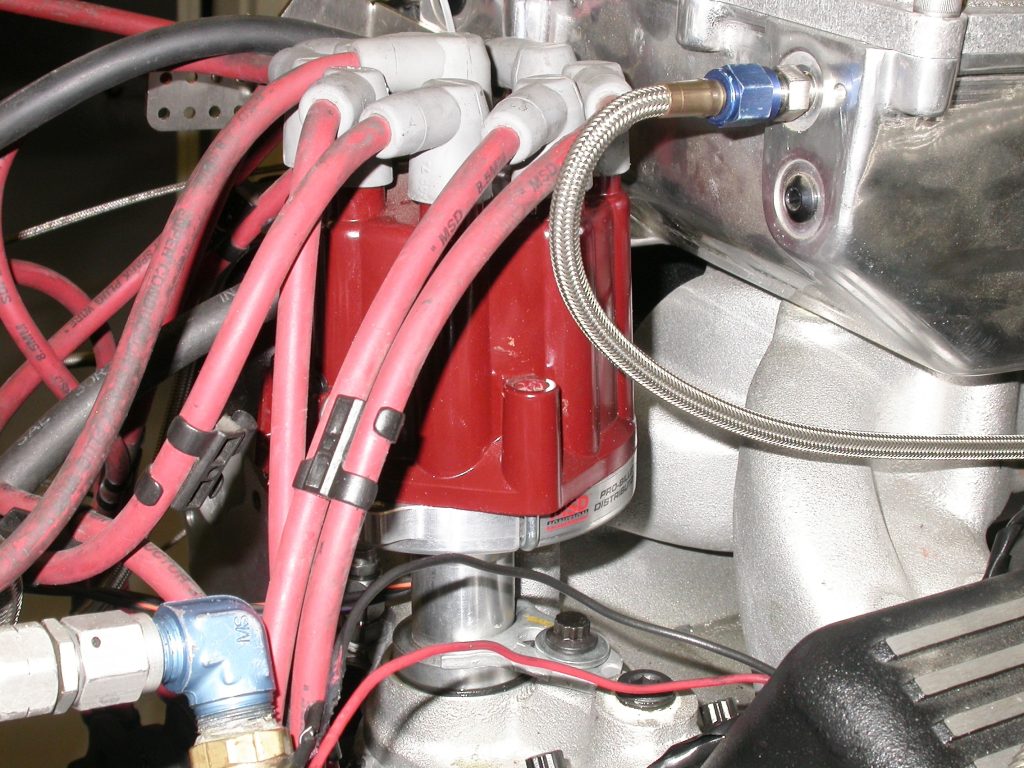

The impressive AFR heads offered enough flow to support over 600 horsepower, much more than our NA 383 was likely to produce. The AFR heads were teamed with an Edelbrock Performer RPM Air Gap intake and Barry Grant 850 Mighty Demon carb. The finishing touches included an MSD ignition system, Moroso valve covers, and an ATI Super Damper.

Sure, a single-plane Victor Jr. Intake would likely make more peak power than the RPM Air Gap, but we wanted solid average power from this combo and that is exactly what it delivered.

Dyno Test Results (With & Without Boost!)

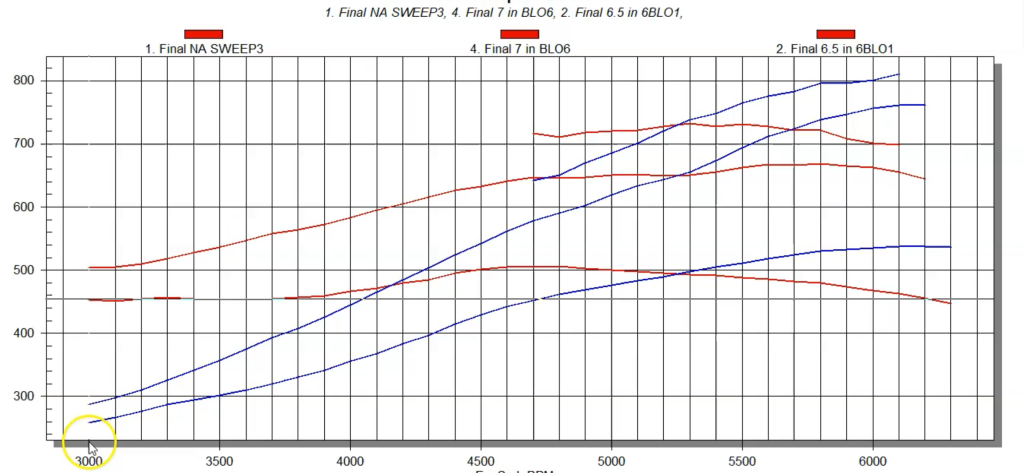

After the break in, the 383 Stroker pumped out peak numbers of 538 hp at 6,200 rpm and 506 lb.-ft. of torque at 4,800 rpm. With the healthy 383 Stroker now making power, we were off to a good start, but things were about to get serious!

A 500+ hp 383 is good, but how do we make it even better? How about increasing the power output by 50% or more?

So…How do you add 50% more power to an already healthy 383 Stroker? Easy, the answer is boost!

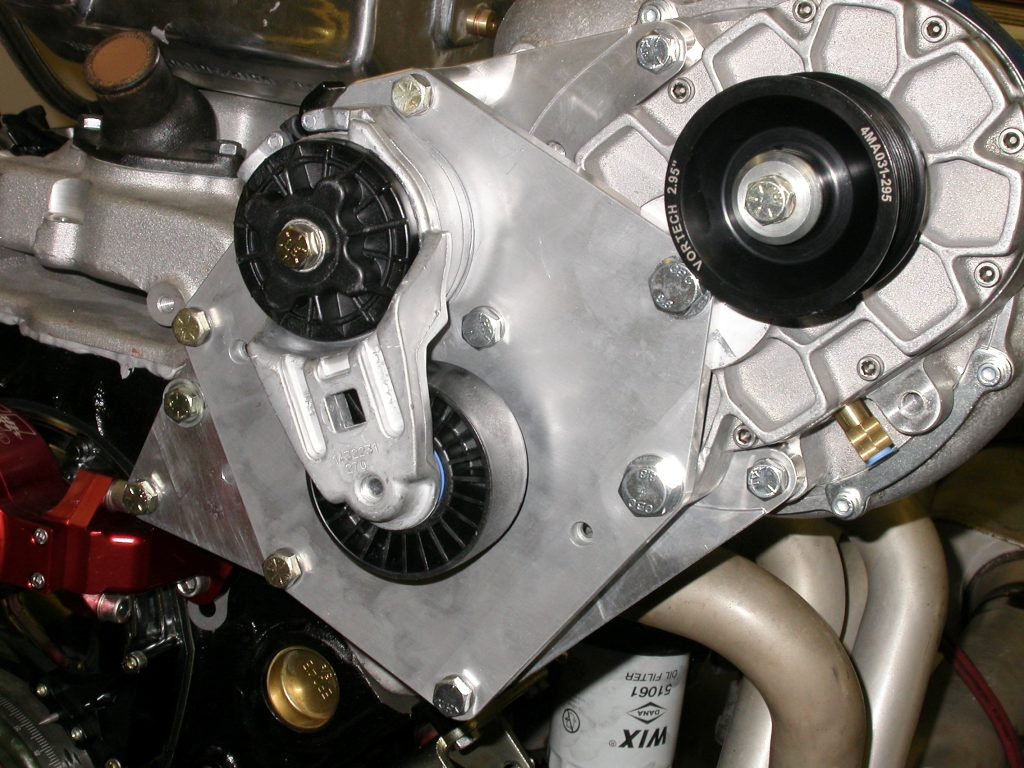

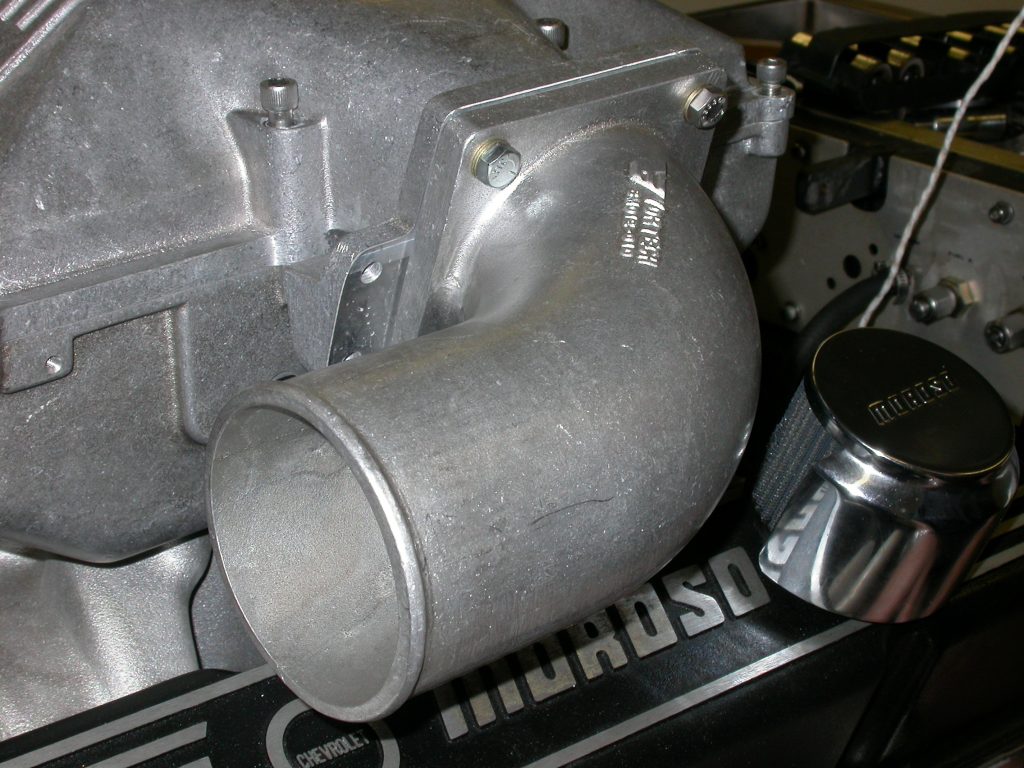

In this case, boost came from a Vortech centrifugal supercharger. We installed the Vortech kit, complete with a 2.95 inch blower pulley and 6.5 inch crank pulley. Equipped with this pulley combo, the T-Trim Vortech supercharged pumped out a maximum of 7.3 psi at 6,200 rpm.

Designed specifically for a carbureted application, the Vortech kit included a dedicated carb enclosure to house a standard (non-blow-through) four-barrel carb. For our test, we ran a 750 Race Demon carb.

We made sure to run a boost reference line to the fuel pressure regulator to ensure that the carb always had seven psi of fuel pressure above the boost pressure. Run in this manner, the Vortech supercharged 383 produced 762 hp and 668 lb.-ft. of torque at a peak boost reading of 7.3 psi. After replacing the 6.5 inch crank pulley with a 7.0 inch pulley, the boost jumped to 9.3 psi and the supercharged combo belted out 811 hp and 732 lb.-ft. of torque.

The T-trim blower had more rpm and flow to offer, and our 383 had plenty of strength, but it was here we called it a day. Imagine what this thing would be like with the Victor Jr. Intake running under boost at 7,000 rpm!

Unless I missed it, the compression ratio was not in the article.

Concur.

Id like this done to my 1984 corvette. Is there a way to make it happen?

Seen it on u tube..